Seal structure for modularized proton exchange film fuel cell

A proton exchange membrane and fuel cell technology, which is applied to fuel cell components, solid electrolyte fuel cells, fuel cells, etc., can solve problems such as uneven aging speed, oxygen leakage, and uneven pressure, and achieve increased performance Safety and safety, production and construction simplification, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

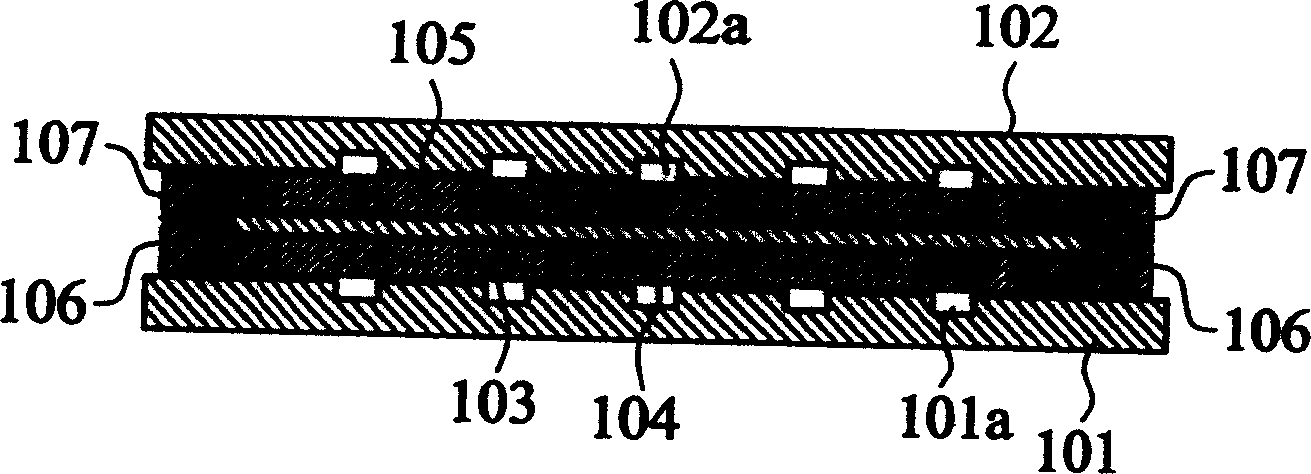

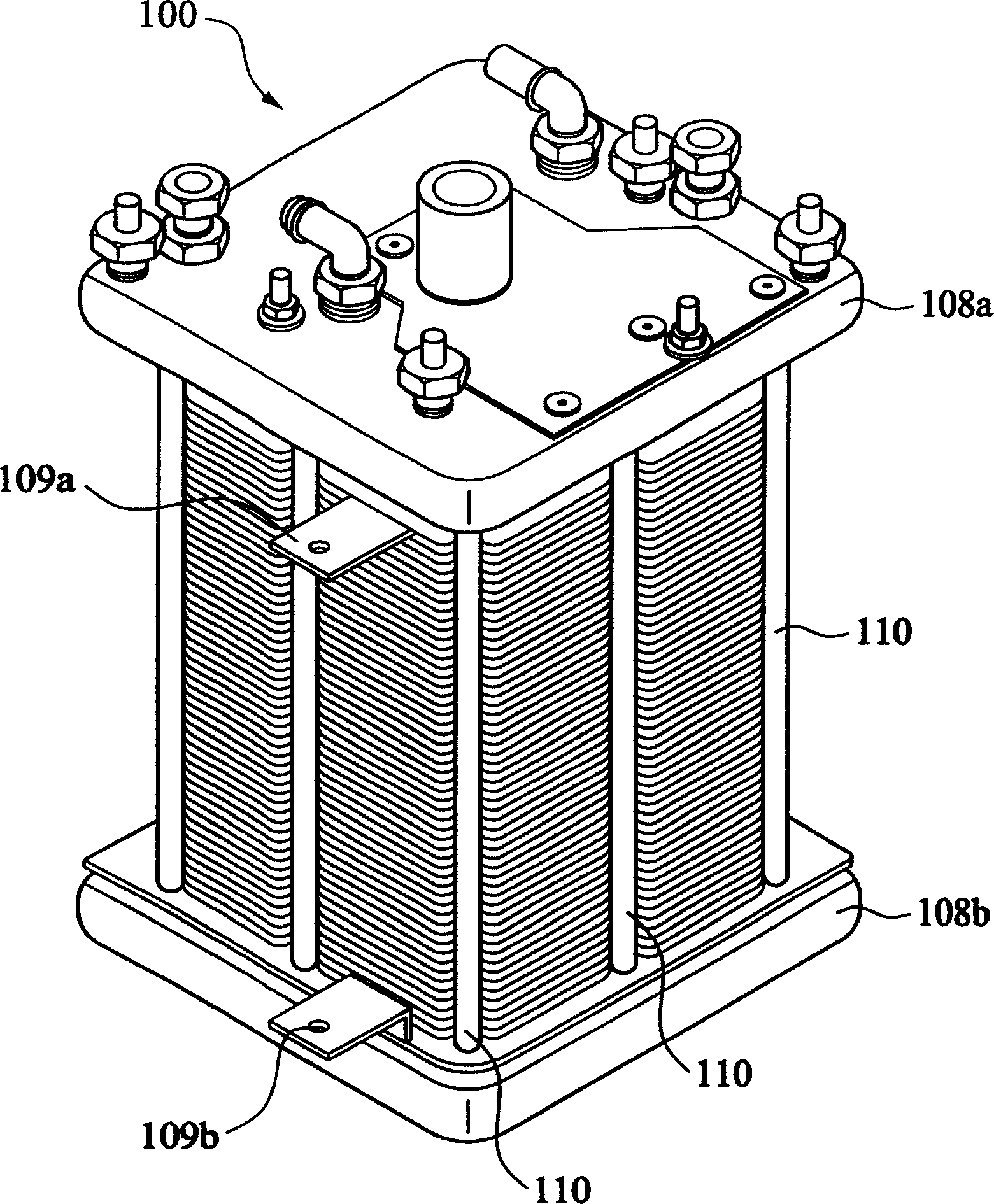

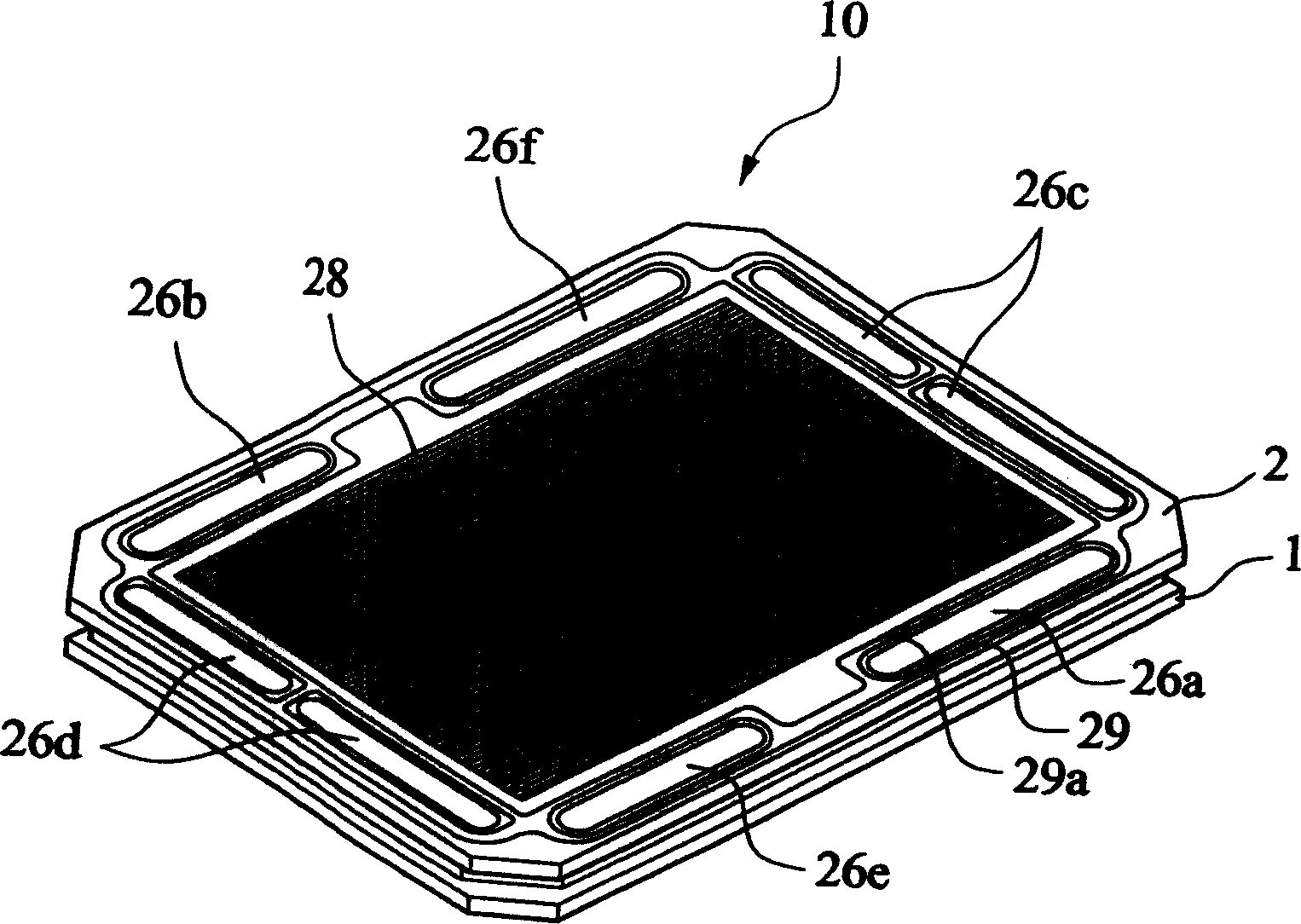

[0107] see first image 3 , which shows a perspective view of the modular fuel cell unit of the proton exchange membrane fuel cell according to the first embodiment of the present invention, Figure 4 for display image 3 The three-dimensional exploded view of each component in separation. Figure 5A for display image 3 A cross-sectional side view of each component in isolation.

[0108] The modularized fuel cell unit 10 shown in the drawings includes an anode plate 1 (Anode Plate) and a cathode plate 2 (Cathode Plate), wherein the anode plate 1 has a first surface 11, a second surface 12, a central The area 13 and a peripheral area 14, the central area 13 of the first surface 11 is provided with a plurality of anode gas channels 15 for the flow of hydrogen gas. The peripheral region 14 of the anode plate 1 is provided with a hydrogen gas inlet through hole 16a, a hydrogen gas outlet through hole 16b, an air inlet through hole 16c, an air outlet through hole 16d, a coolan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com