Composite wall body

A composite wall and exterior wall panel technology, which is applied to building components, applications, household appliances, etc., can solve problems such as poor bonding of walls, cumbersome construction, and inability to meet thermal insulation requirements, so as to improve performance in all aspects and manufacture The effect of convenient construction and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

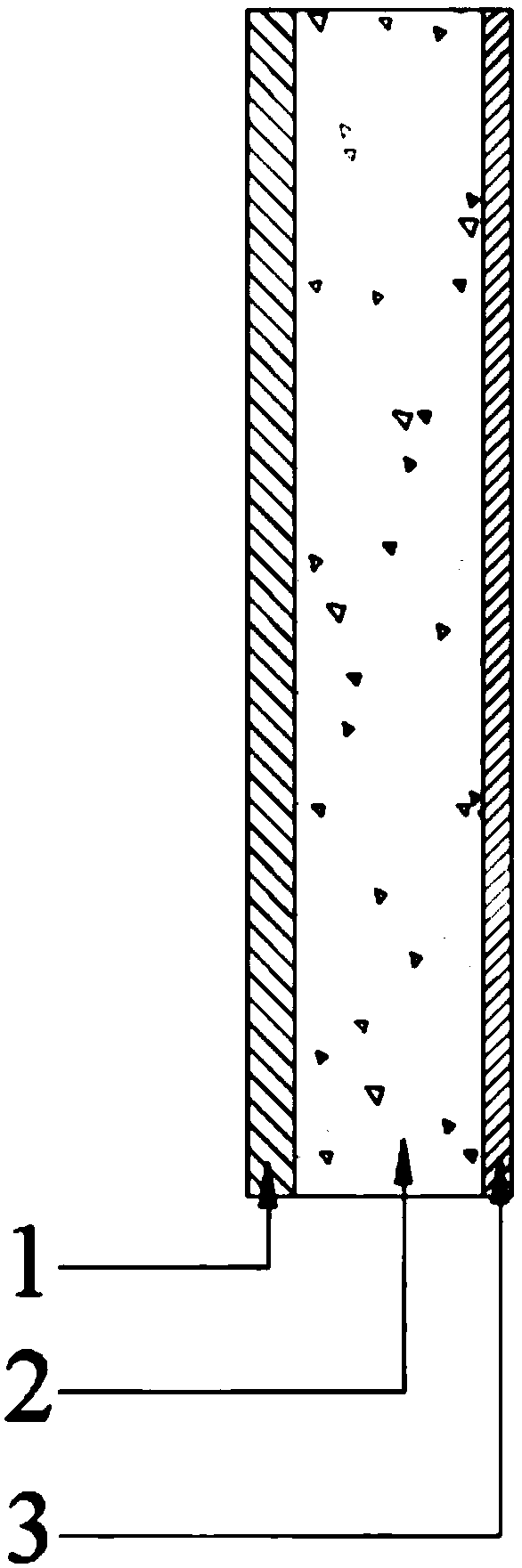

[0024] Such as figure 1 As shown, the composite wall body of the present embodiment comprises: exterior wall panel 1, interior wall panel 3, steel skeleton ( figure 1 ) and filling layer 2, the bottom of the steel skeleton is fixed on the ground or on the base and base on the bottom surface, the outer wall panel 1 is connected (installed) on the outer side of the steel skeleton, and the inner wall The board 3 is connected (installed) inside the steel skeleton, and the filling layer 2 is a foam material filled (cast) between the outer wall board 1 and the inner wall board 2 .

[0025] The exterior wall panel 1 is a flat prefabricated wall panel, its thickness is usually 2.5cm to 5cm, and its material is a high-strength fiber cement board. The composition of the material includes: cement, mine waste, lignocellulose, straw powder, and water reducer , Alkali-resistant glass fiber and concrete waterproofing agent, the material ratio (by mass) is: 1 cement, 1-2.5 mine waste, 0.0045...

Embodiment 2

[0035] The material ratio of the exterior wall panel 1 in this embodiment is: 1 cement, 1.5 mine waste, 0.005 lignocellulose, 0.2 straw powder, 0.005 water reducer, 0.005 alkali-resistant glass fiber, 0.03 concrete waterproofing agent, 0.45 water.

Embodiment 3

[0037] The material ratio of the exterior wall panel 1 in this embodiment is: 1 cement, 2.5 mine waste, 0.0055 lignocellulose, 0.22 straw powder, 0.01 water reducer, 0.01 alkali-resistant glass fiber, 0.05 concrete waterproofing agent, 0.5 water.

[0038] The composite wall of the present invention includes exterior wall panels, interior wall panels, steel skeletons and filling layers, all parts are tightly combined, and the material properties are excellent, so that the composite wall has better firmness, stability, water resistance, and fire resistance. , thermal insulation and sound insulation, prolong the service life of the composite wall, and the construction is convenient and fast, environmentally friendly and energy-saving. Therefore, the performance of this composite wall is better than that of the prior art in all aspects, and it is easy to popularize and use .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com