Full-automatic drilling production line and production process thereof

A production process, fully automatic technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, unable to meet large-scale production, and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

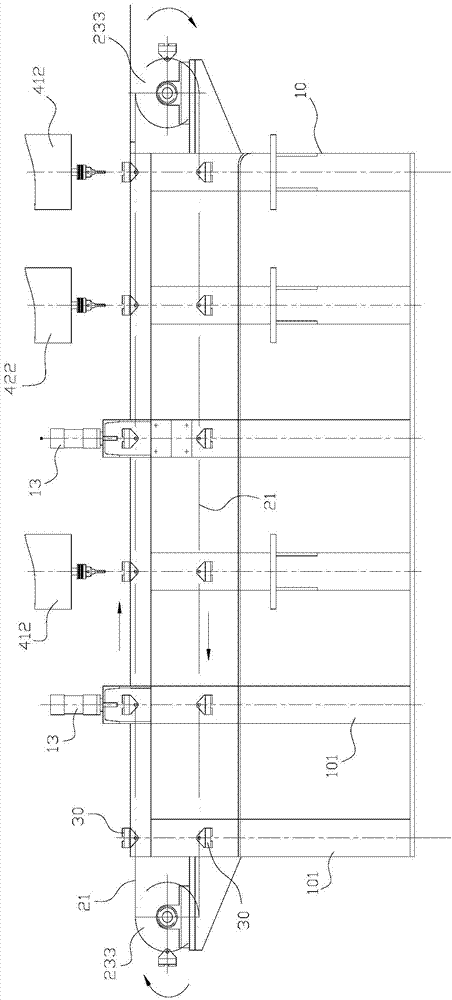

[0037] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

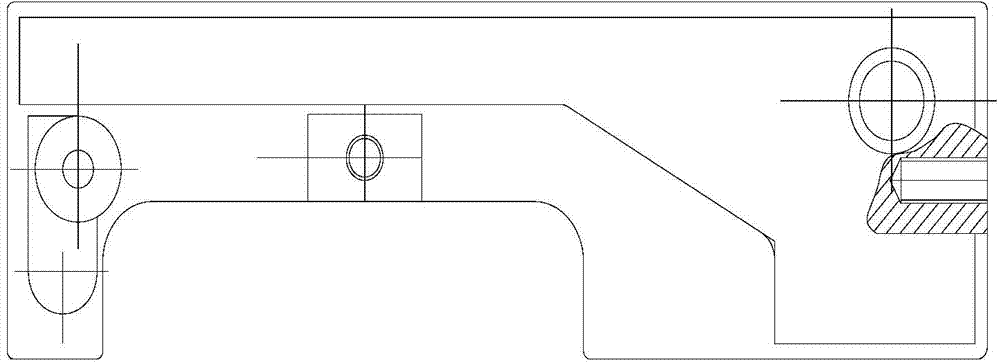

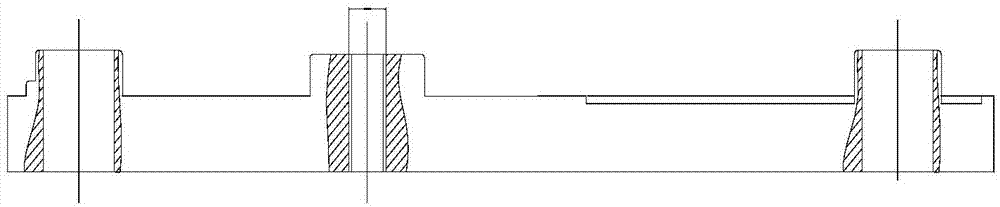

[0038] see Figure 2a , Figure 2b and image 3 , the present invention provides a fully automatic drilling production line for drilling or tapping a workpiece, which includes:

[0039] The frame 10 is provided with a bearing platform 11;

[0040] The transmission device is arranged on the frame 10, the transmission device includes a conveyor belt 21 and a stepping motor 22, and the stepping motor 22 drives the conveyor belt 21 to operate;

[0041] A plurality of carriers 30 are arranged at intervals on the conveyor belt 21 for placing workpieces;

[0042] Drilling device, which is arranged on the frame 10, for drilling the workpiece on the carrier 30, including a drilling machine 41 and a first pushing mechanism;

[0043] The tapping device, which is arranged on the frame 10 and behind the drilling device, is used for tapping the drilled workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com