Automatic riveting device

A riveting and automatic technology, applied in the field of automatic riveting equipment, can solve the problems of not being able to meet large-scale batch processing, affecting the production and processing efficiency of processed parts, and increasing product production costs, so as to save labor costs, improve production and processing efficiency, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

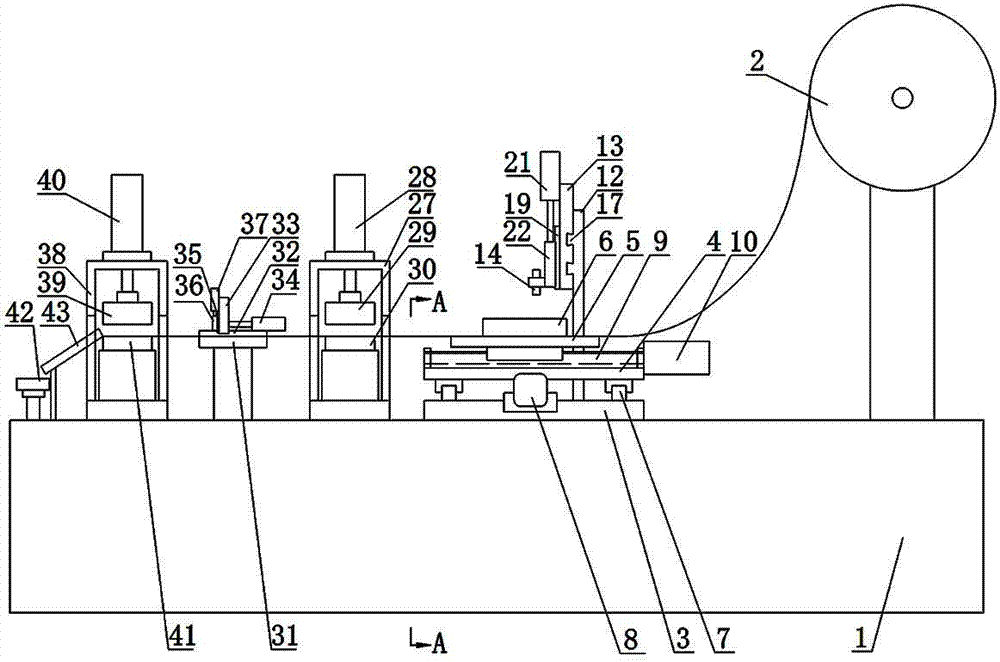

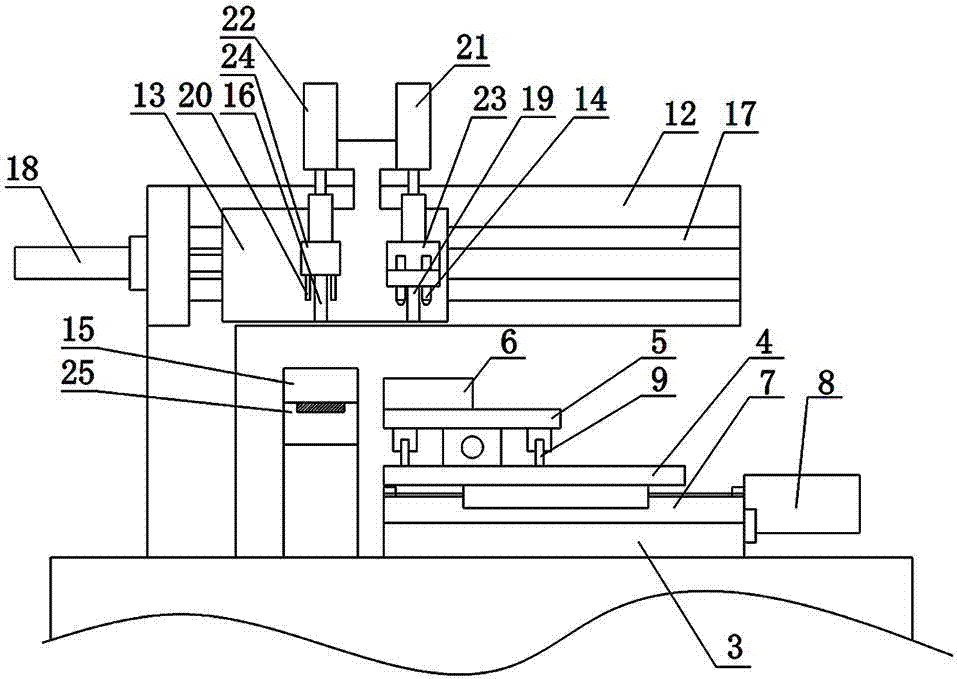

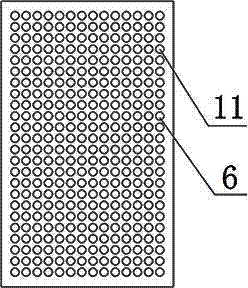

[0019] Such as figure 1 As shown, the automatic riveting equipment includes a frame 1, a tape storage tray 2 sequentially arranged on the frame 1, a rivet feeding device, a riveting device, a dragging device and a shearing device; 2 is installed on the frame 1 through the rotating shaft, such as figure 1 , figure 2 The rivet feeding device includes a rivet feeding device and a rivet installation device. The rivet feeding device includes a base 3, an X-direction slide plate A4, a Y-direction slide plate A5 and a feeding mold 6. The base 3 is fixed on the frame 1. On the surface, the base 3 is provided with an X-direction rail A7, an X-direction screw rod and an X-direction stepping motor 8, and the two ends of the X-direction screw rod are installed on the base 3 through bearings, and the X-directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com