Press fitting device for guide pipe and seat retainer of engine cylinder head

A technology for an engine cylinder head and a press-fitting device, applied in the field of press-fitting devices, can solve the problems of unsuitability for mass production, low press-fitting efficiency, low press-fitting accuracy, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

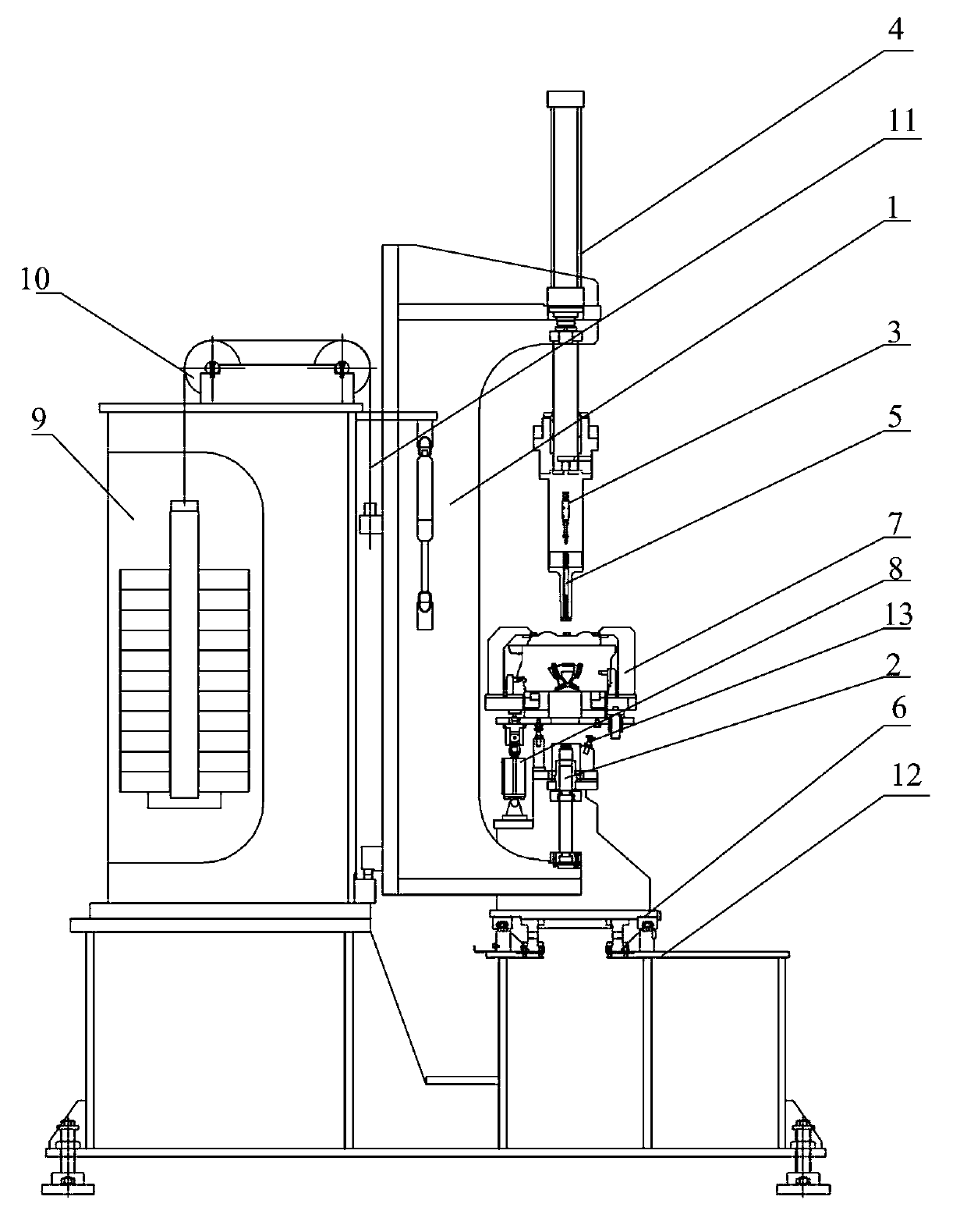

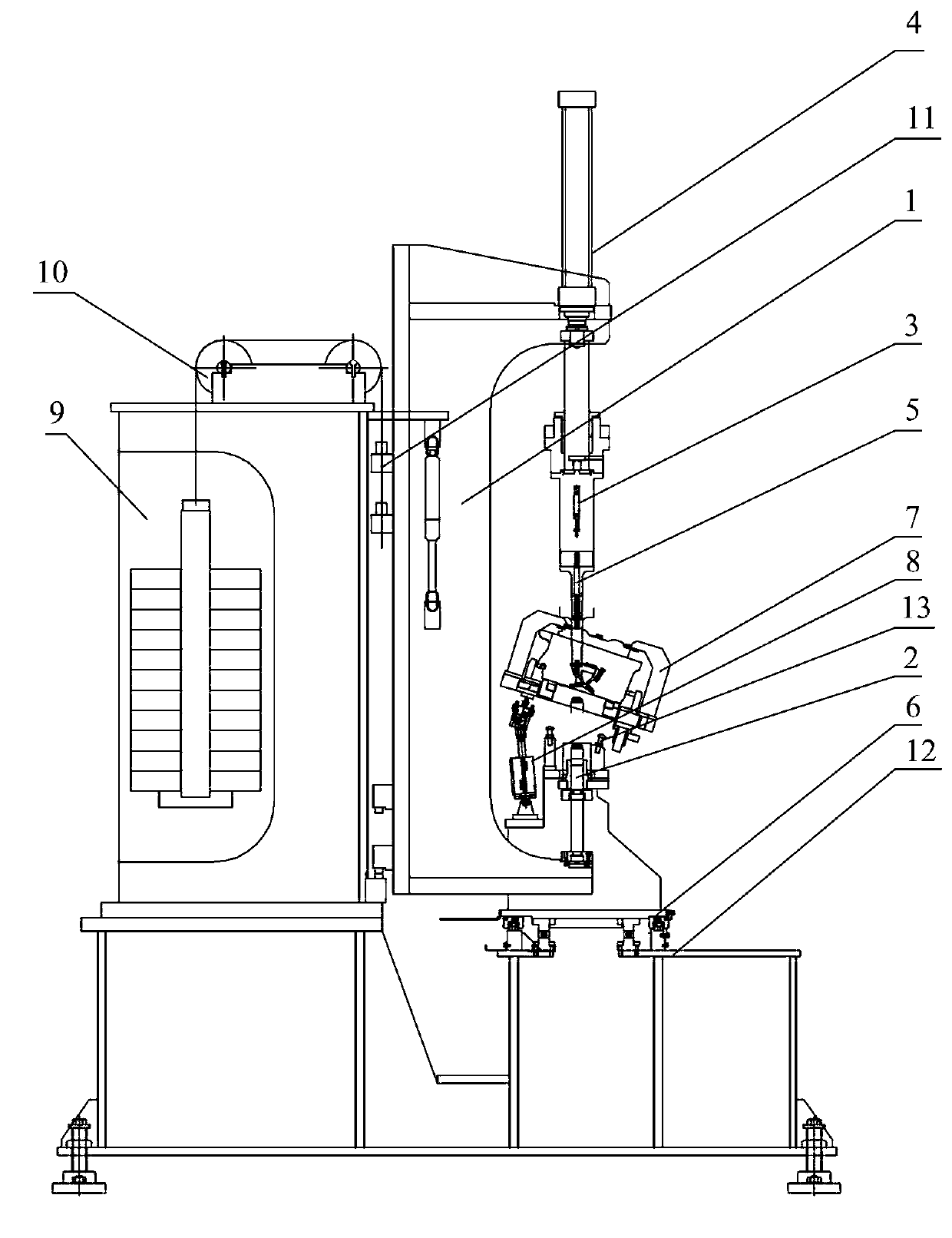

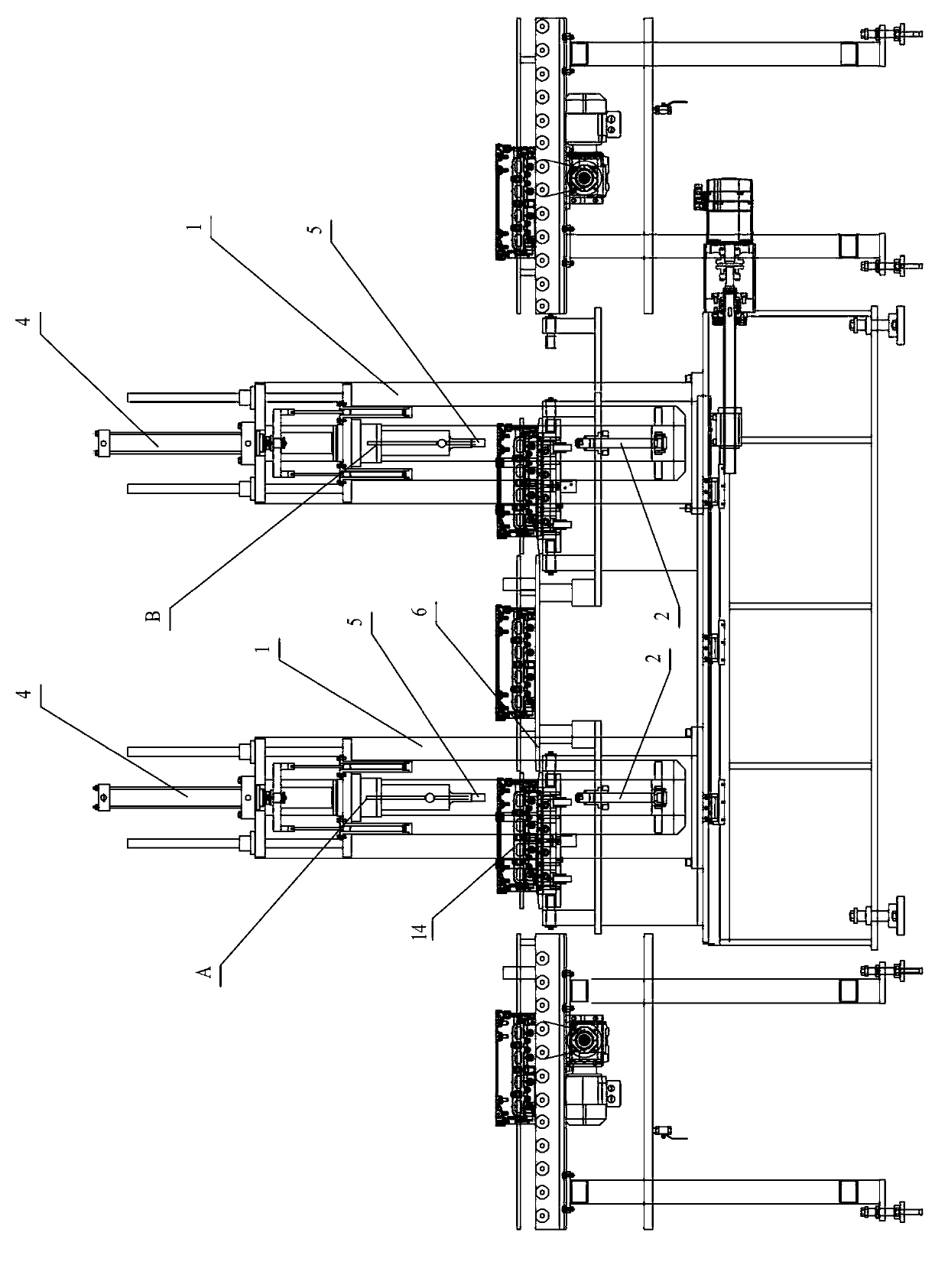

[0025] The engine cylinder head conduit that this embodiment relates to, the seat ring press-fitting device, its structure is as follows figure 1 , figure 2 Shown: including: a conveying clamping mechanism controlled by the main control unit, a press-fit mechanism, and a fixed support mechanism for supporting the press-fit device.

[0026] The conveying and clamping mechanism is used to transport the engine cylinder head 14 to the press-fitting station, and clamps the engine cylinder head 14, including a moving slide 6 slidably arranged on the support 12, the moving slide Under the control of the main control unit, the table 6 can slide on the support 12 through the promotion of the horizontal cylinder. On the movable slide table 6, a fixed fixture 7 is provided with a convertible angle, which is used to clamp the engine cylinder head 14. The work is controlled by the main control unit. In order to ensure that the fixing fixture 7 is just aligned with the press-fitting sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com