Ultrasonic automatic food cutting production line

An ultrasonic and production line technology, which is applied in the field of ultrasonic automatic food cutting production line, can solve the problems of large error, sticking knife, and unable to meet the mass production of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

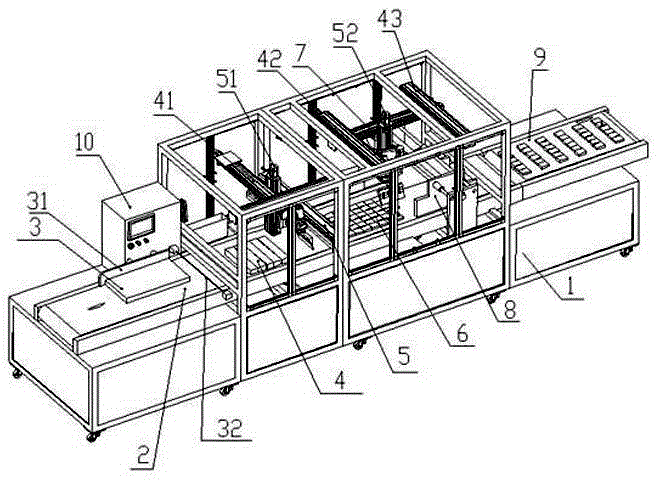

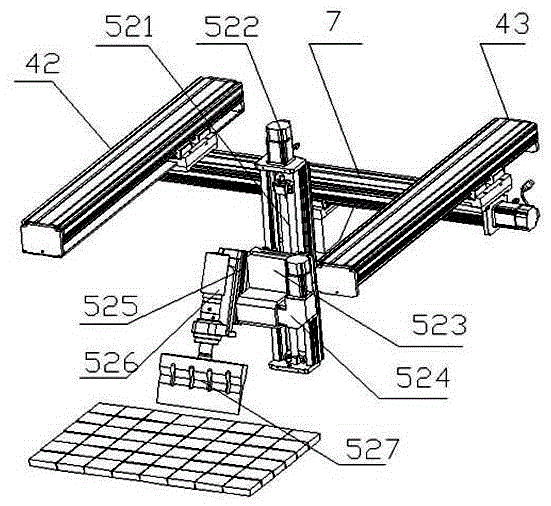

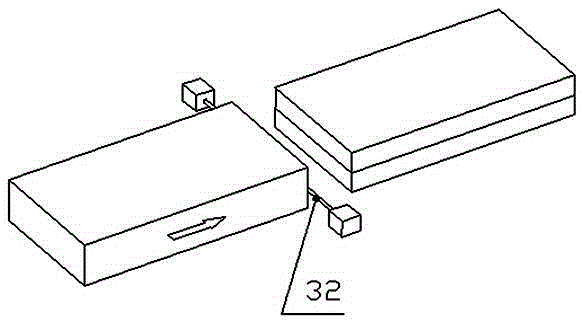

[0013] In this example, if Figure 1 to Figure 3 As shown, an ultrasonic automatic food cutting production line of the present invention is suitable for cutting foods such as bread, cheese, chocolate, cakes, nuts, etc., and includes a machine 1 and a food conveyor belt arranged on the top of the machine 1 2, and the position 3 for placing food by hand on the left end of the food conveyor belt 2, and the food positioning baffle 31 arranged on the side of the position 3 for placing food by hand, and the horizontal horizontal panel on the right side of the position 3 for placing food by hand. Cutting station 4, and the ultrasonic vibrating steel wire 32 or blade that is arranged between the food position 3 and the cross-cutting station 4, which can cut the food layer, and the first one above the cross-cutting station 4 The cross-cutting slide assembly 41, and the first ultrasonic cutting mechanism 51 connected to the first cross-cutting slide assembly 41, and the front and rear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com