Simulation method for residual stress prediction of micro-milling nickel-based superalloy

A technology of nickel-based superalloy and simulation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc. It can solve the problems that cutting parameters cannot be considered and simulation results are consistent, so as to save manpower, realize prediction and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention is described in detail below in conjunction with technical scheme and accompanying drawing, use finite element calculation software ABAQUS, carry out three-dimensional finite element simulation to micro-milling nickel-base superalloy processing process, predict surface residual stress distribution and size, concrete simulation steps are as follows:

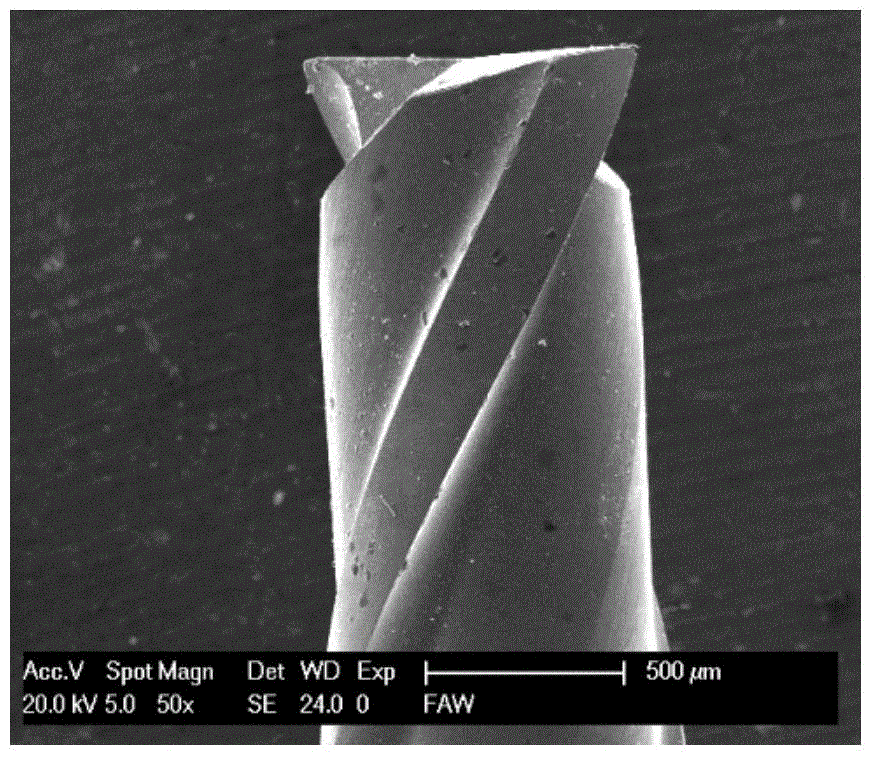

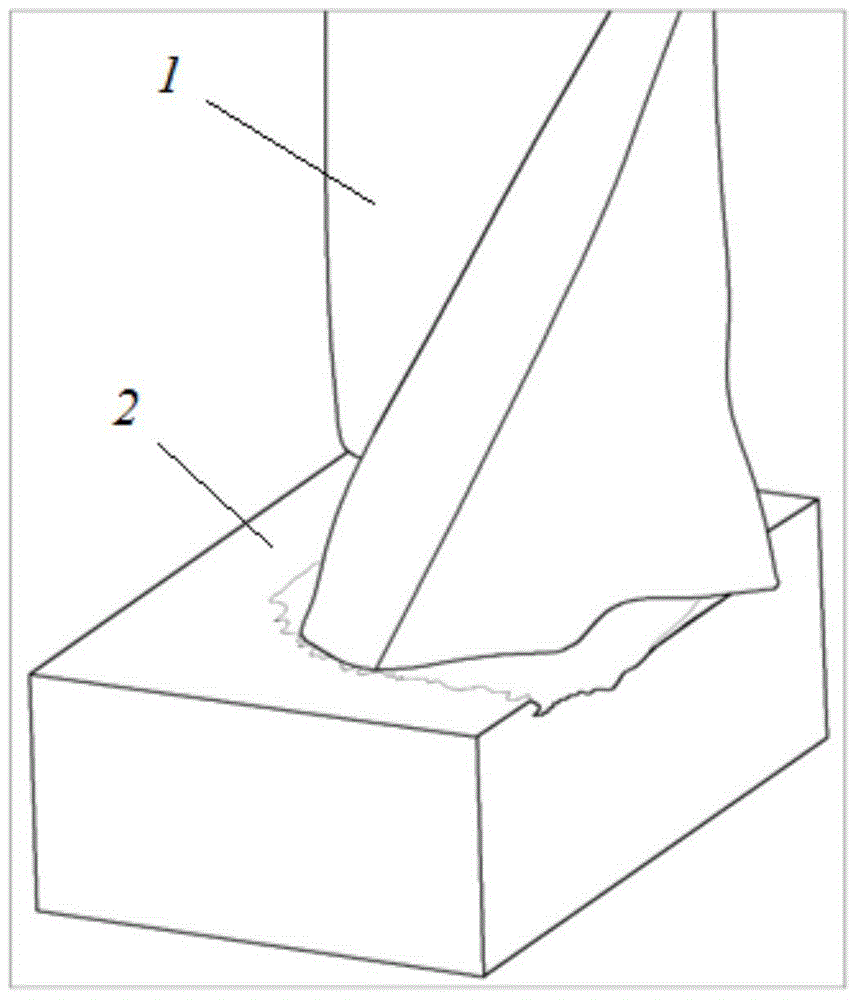

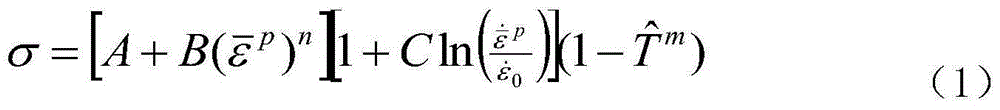

[0026] (1) In the three-dimensional finite element simulation, the tool model is a micro milling cutter MX230 produced by Japan NS Company, the tool diameter D = 1mm, the edge arc radius is 0.002mm, the helix angle β = 30°, and the edge length L = 2mm. According to the scanning electron microscope to take pictures of the micro milling cutter, such as figure 1 shown. The plan view of the rotating edge of the micro-milling cutter was drawn by AutoCAD software. Then import the CAD two-dimensional drawing into the Pro / E three-dimensional modeling software, start from the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com