Milling forming production method of dental all-ceramic restoration

A manufacturing method and restoration technology, applied in dentures and other directions, can solve the problems of reducing the long-term stability and reliability of restorations, too thin and cracked restorations, restoration failures of restorations, etc., so as to improve the smoothness of the outer surface and the uniform and coherent structure of the restoration. , The effect of improving the processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

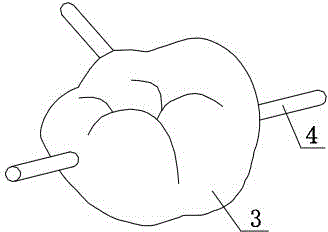

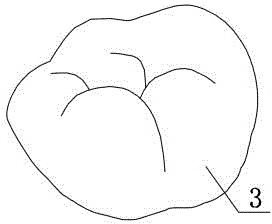

[0057] According to the case and the restoration plan: the posterior teeth are large-area dental defects, and the posterior teeth zirconia single crown all-ceramic restorations are made.

[0058] A method of milling and forming dental all-ceramic restorations, as attached image 3 As shown, including the following steps:

[0059] Step 1: Perform conventional tooth preparation according to the tooth preparation standards of zirconia all-ceramic restorations: occlusal surface grinding 1.5mm~2.0mm, axial surface grinding 1.0~1.5mm, neck shoulder width 0.5~0.8mm, Axial surface polymerization degree is 6~8℃, each point angle and line angle are round and smooth.

[0060] Step 2: Use the 3Shape intraoral scanner TROIS to directly scan the upper and lower dentition to obtain an optical model of the dentition.

[0061] Step 3: Take the optical model of the dentition obtained in step 2 as the data source, and use the dental restoration design software 3Shape dental CAD system DentalDesigner TM...

Embodiment 2

[0069] According to the case and the restoration plan: the posterior teeth were large-area dental defects, and the posterior teeth zirconia-alumina composite single-crown all-ceramic restorations were made.

[0070] Step 1: Perform conventional tooth preparation according to the tooth preparation standard of all-ceramic restorations: occlusal surface grinding 1.5mm~2.0mm, axial surface grinding 1.0~1.5mm, neck shoulder width 0.5~0.8mm, axial surface The degree of polymerization is 6~8℃, and the angles of each point and line are round and smooth.

[0071] Step 2: Make the upper and lower dentition impressions clinically, use the 3Shape desktop scanner D810 to directly scan the dentition impressions, and use the dental restoration design software 3Shape dental CAD system DentalDesigner TM Converted into an optical model of dentition.

[0072] Step 3: Take the optical model of the dentition obtained in step 2 as the data source, and use the dental restoration design software 3Shape de...

Embodiment 3

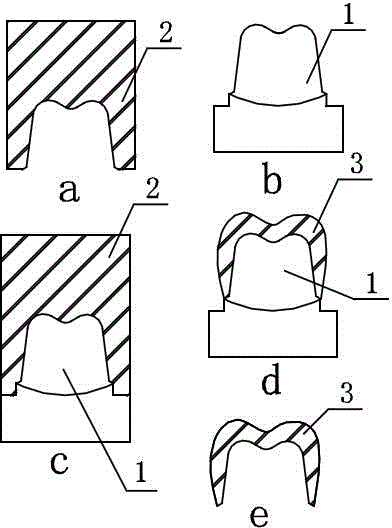

[0080] According to the case and the restoration plan: the posterior teeth were large-area dental defects, and the posterior teeth zirconia-alumina composite single-crown all-ceramic restorations were made.

[0081] A method of milling and forming dental all-ceramic restorations, as attached Figure 4 As shown, including the following steps:

[0082] Step 1: Perform conventional tooth preparation according to the tooth preparation standards of all-ceramic restorations: occlusal surface grinding 1.5mm~2.0mm, axial surface grinding 1.0~1.5mm, neck shoulder width 0.5~0.8mm, axial surface The degree of polymerization is 6~8℃, and the angles of each point and line are round and smooth.

[0083] Step 2: Make the upper and lower dentition impressions clinically, use the 3Shape desktop scanner D810 to directly scan the dentition impressions, and use the dental restoration design software 3Shape dental CAD system DentalDesigner TM Converted into an optical model of dentition.

[0084] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com