Shear-and-low-temperature coupling experimental device and method for through cracks

An experimental device and fissure technology, applied in the field of fracture mechanics and rock mechanics, can solve the problem of no relevant introduction, etc., and achieve the effect of easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

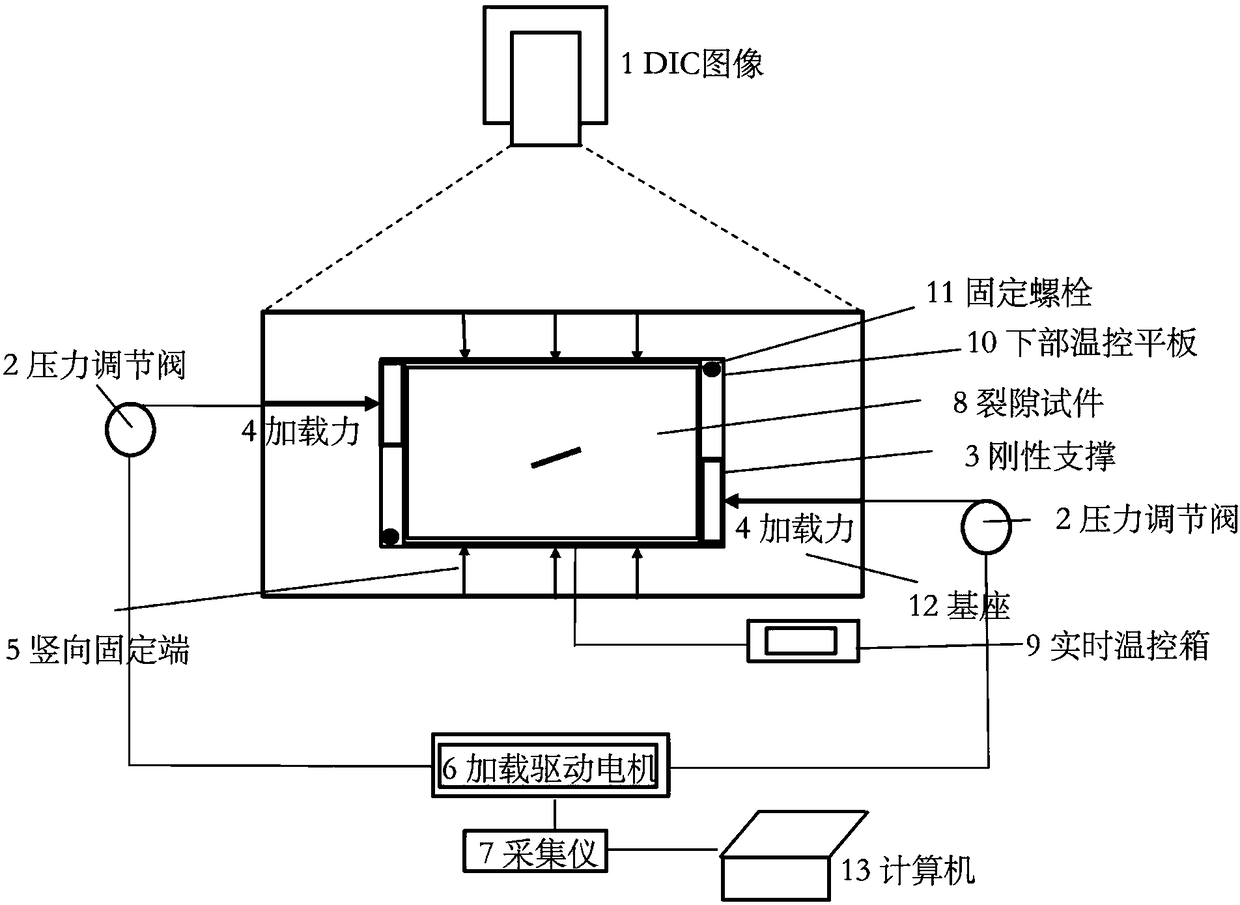

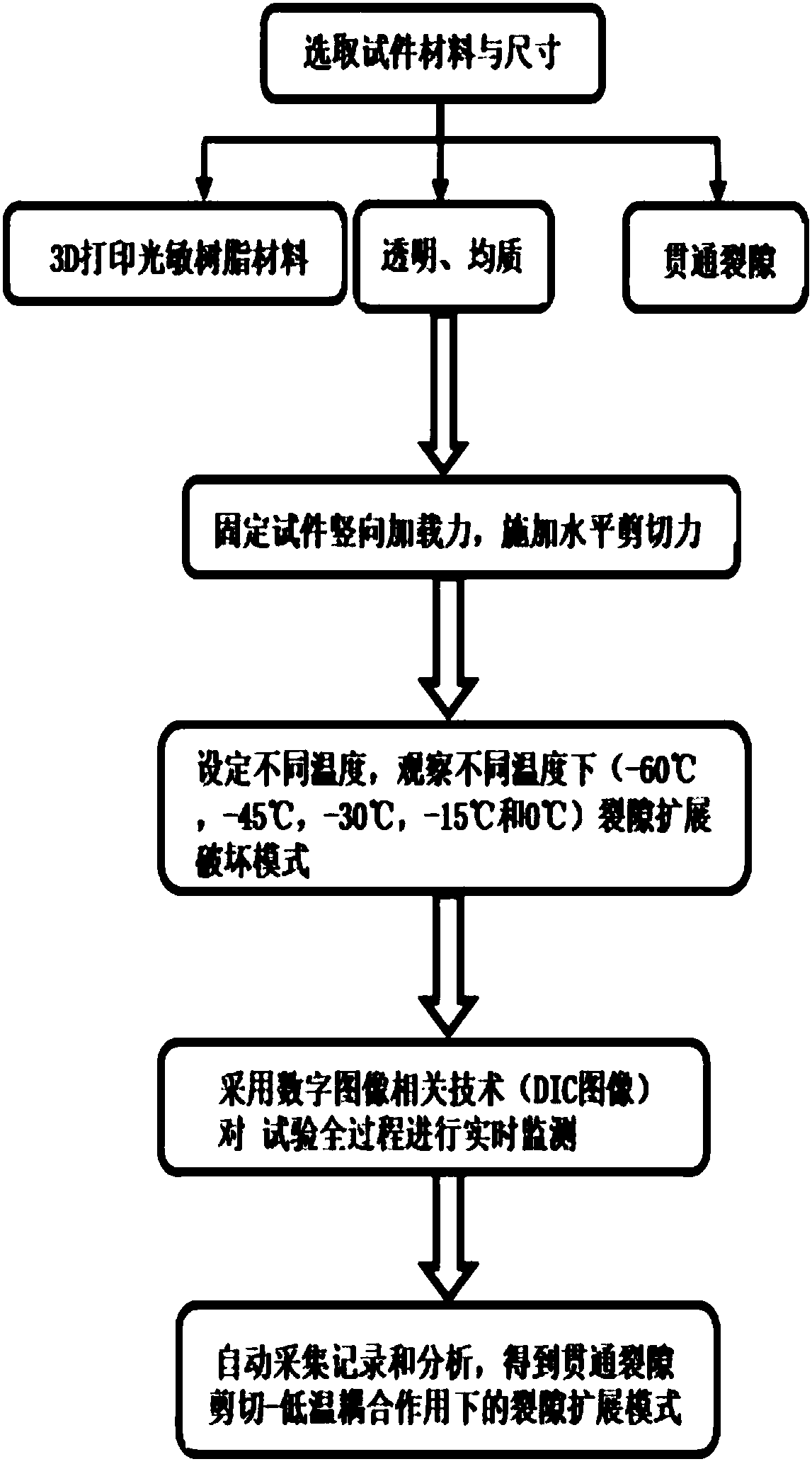

[0030] In this embodiment, 3D printing technology is used to prepare a crack specimen of photosensitive resin material. The length and width of the specimen are both 10 cm, and the height of the specimen is 6 cm; the length of the crack is 4 cm, and the shape is a cuboid structure. When carrying out the test, the lower temperature control panel 10 is placed above the base, and the lower temperature control panel 10 is connected to the real-time temperature control box 9, so as to ensure that the temperature at the bottom is transmitted to the test piece in real time, and the real-time temperature control box 9 can be intuitively See the temperature and time settings. Then place the crack test piece above the lower temperature control plate 10, the crack test piece is vertically fixed end 5, apply vertical force to the vertical fixed end, and then the two X-direction loading heads can be loaded in the horizontal direction , the size of the horizontal loading force given by each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com