Dynamic bioabsorbable fastener for use in wound closure

a bioabsorbable and dynamic technology, applied in the direction of surgical staples, prostheses, osteosynthesis devices, etc., can solve the problems of viscoelastic quality or polymer creep of thermoplastic polymers used in typical bioabsorbable staples, and achieve the effect of increasing the lateral pressure of the bioabsorbable fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

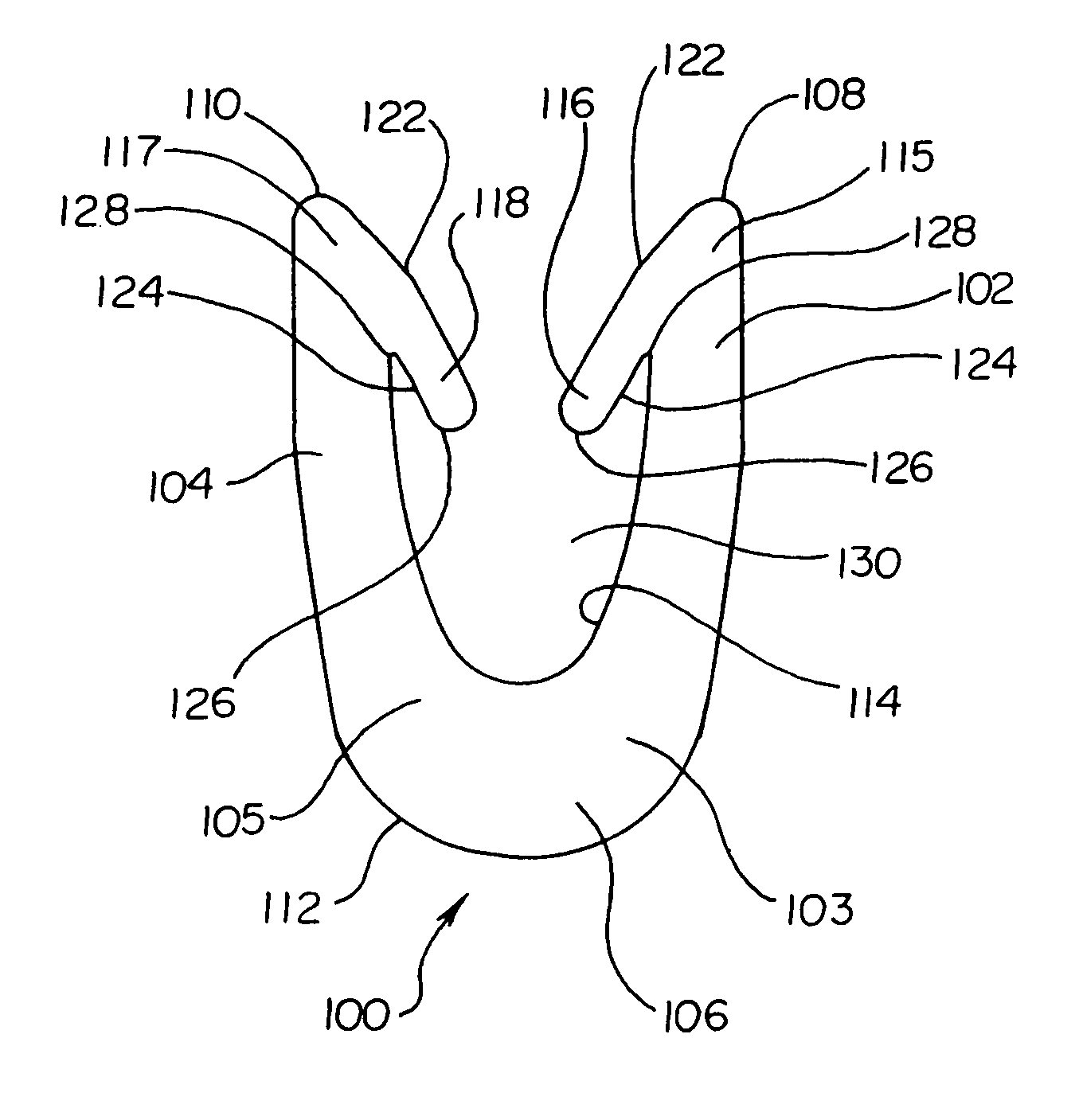

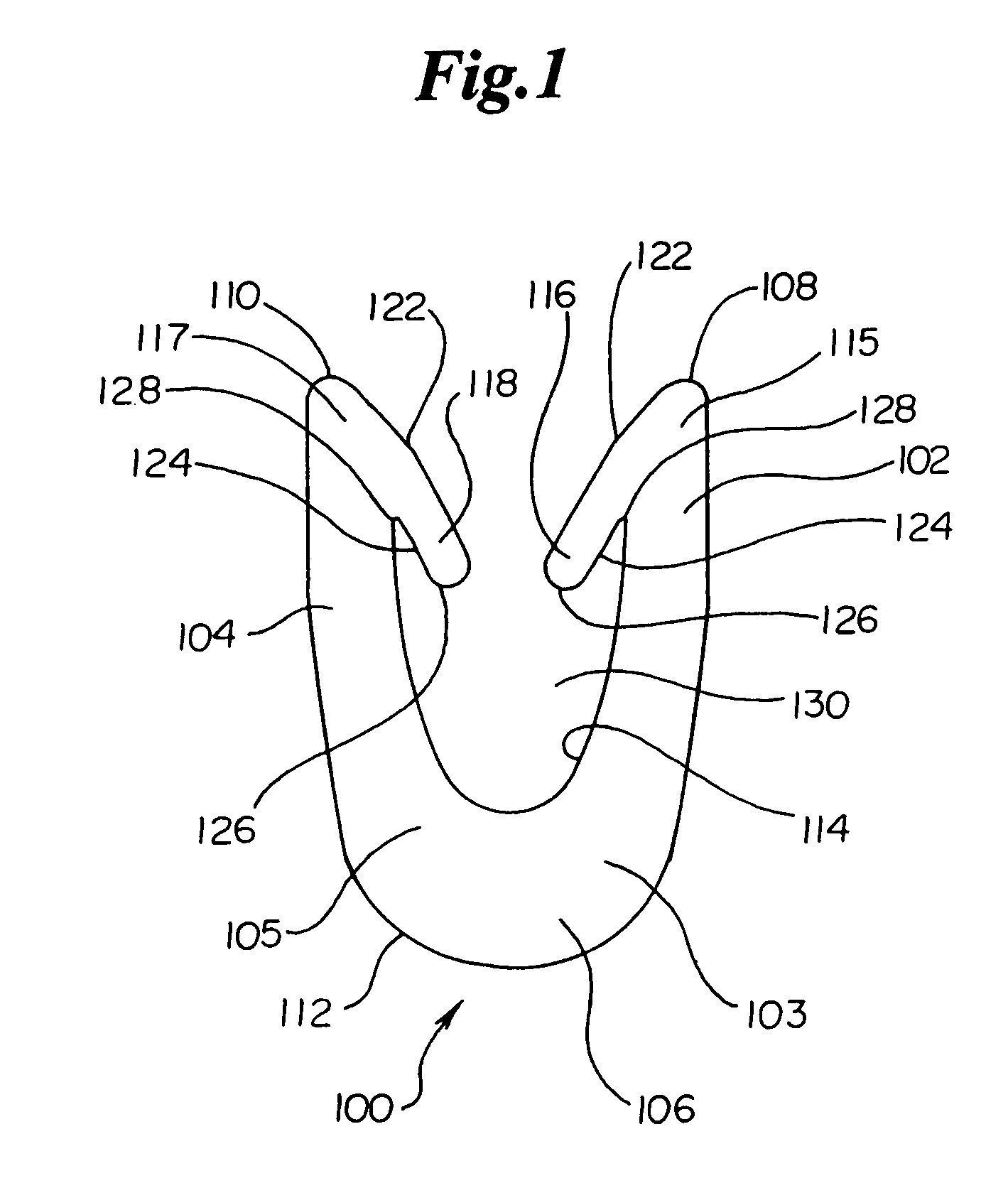

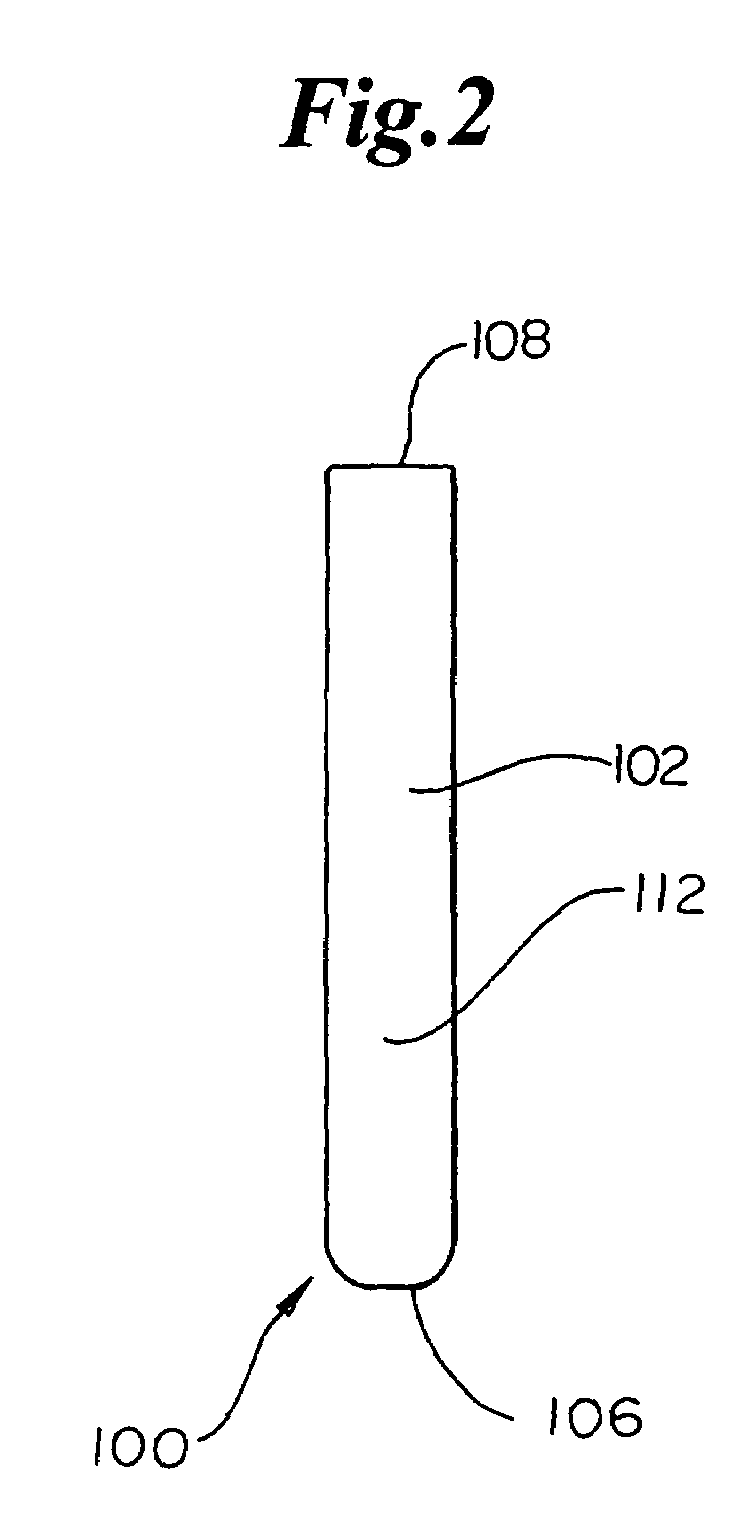

[0048]Depicted in FIGS. 1–3 is a preferred embodiment of a dynamic, bioabsorbable fastener 100 of the present invention. Generally, fastener 100 comprises a pair of arms102, 104 being operably connected with a common backspan 106 at shoulder portions 103 and 105, also depicted in FIG. 5, respectively. Arms 102, 104 each preferably include a rounded tip 108, 110. Fastener 100 is further defined by an arcuate exterior, perimeter surface 112 and an arcuate interior surface 114. The arcuate shape of interior surface 114 functions to even out and focus staple loading forces and reduces potential rocking of fastener 100 when in place within tissue. Most typically, fastener 100 has a generally circular cross-section taken through backspan 106 that gradually tapers to a more rectangular cross-section. In order to facilitate mold removal, fastener 100 can include a plurality of distinct segments and surfaces as shown for example in FIGS. 3 and 29.

[0049]Depending from each of tips 108, 110 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com