A hydraulic liquid plastic expanding mandrel fixture

A technology of expanding mandrel and hydraulic fluid, applied in the field of hydraulic fluid-plastic expanding mandrel fixture, to achieve the effects of high processing efficiency, reduced deformation of parts, high precision and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

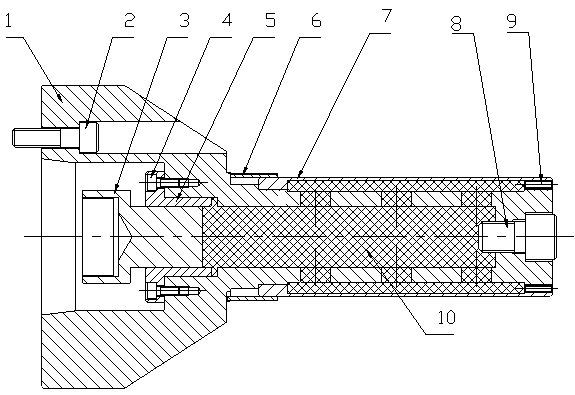

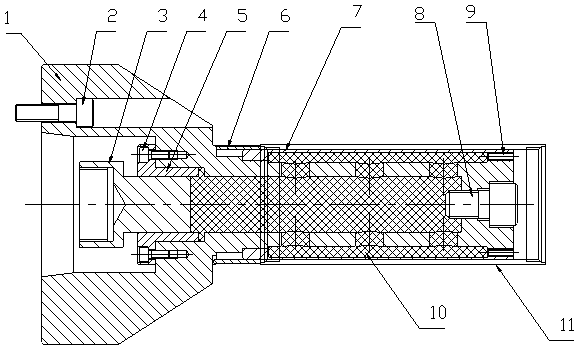

[0031] Such as figure 1 As shown, the hydraulic liquid plastic expansion mandrel clamp of the present invention includes a clamp body 1 made of ductile iron material, and the clamp body 1 includes a connecting part connected with a machine tool and a tensioning part for tensioning the cylinder. An assembly screw 2 is fixed on the connecting portion of the fixture body 1 , and the fixture body 1 is fixed on the machine tool through the assembly screw 2 . A cavity 10 is provided inside the clamp body 1, and the cavity 10 runs through the connection part and the tightening part. The cavity 10 has an axisymmetric structure.

[0032] A connecting sleeve 5 is fixedly arranged in the cavity in the connecting portion of the fixture body 1 by fastening screws 4 , and the connecting sleeve 5 is coaxial with the fixture body 1 . The inner wall of the connecting sleeve 5 is slidably connected to the pull rod 3 , and the pull rod 3 is coaxial with the connecting sleeve 5 . The cavity 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com