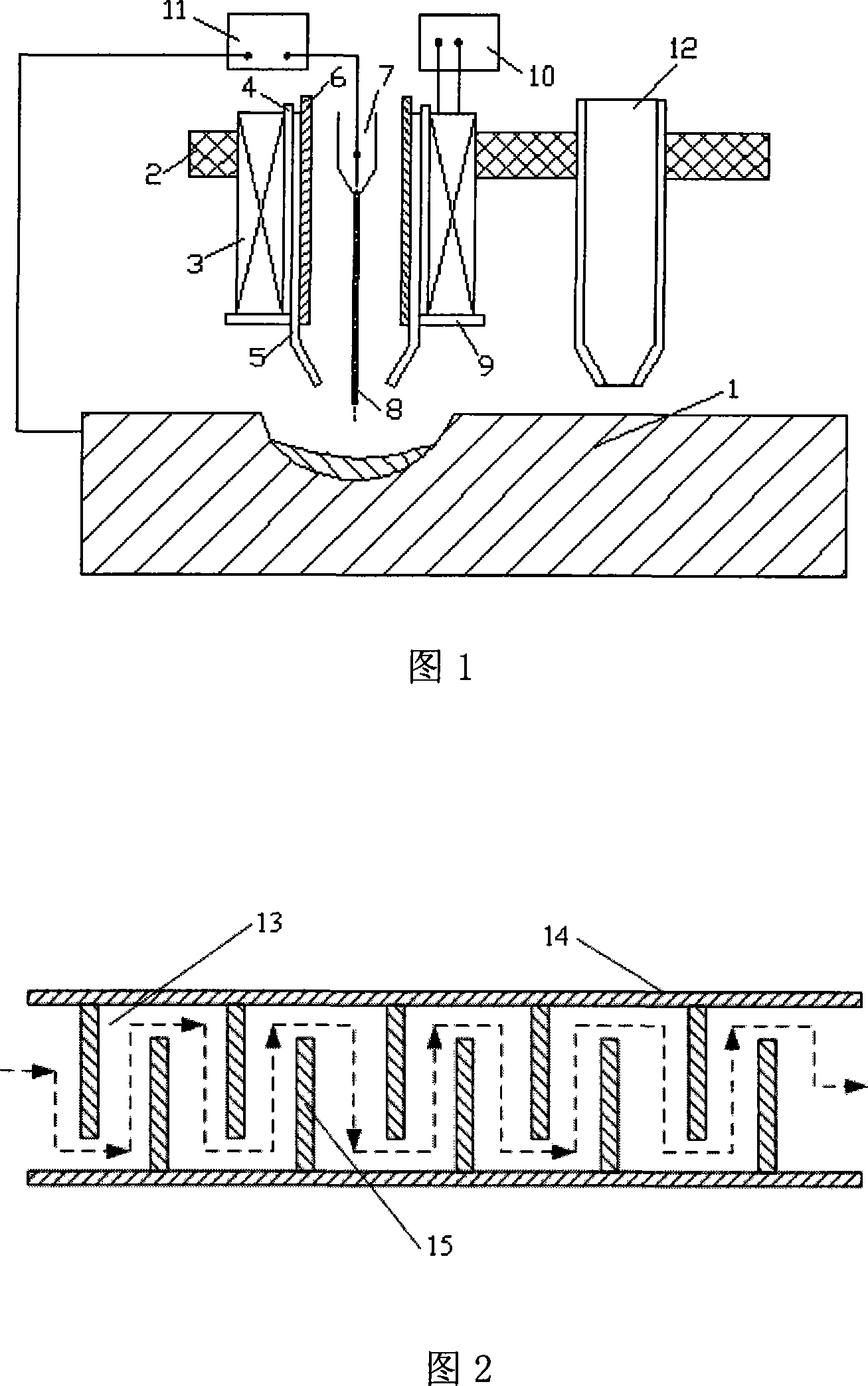

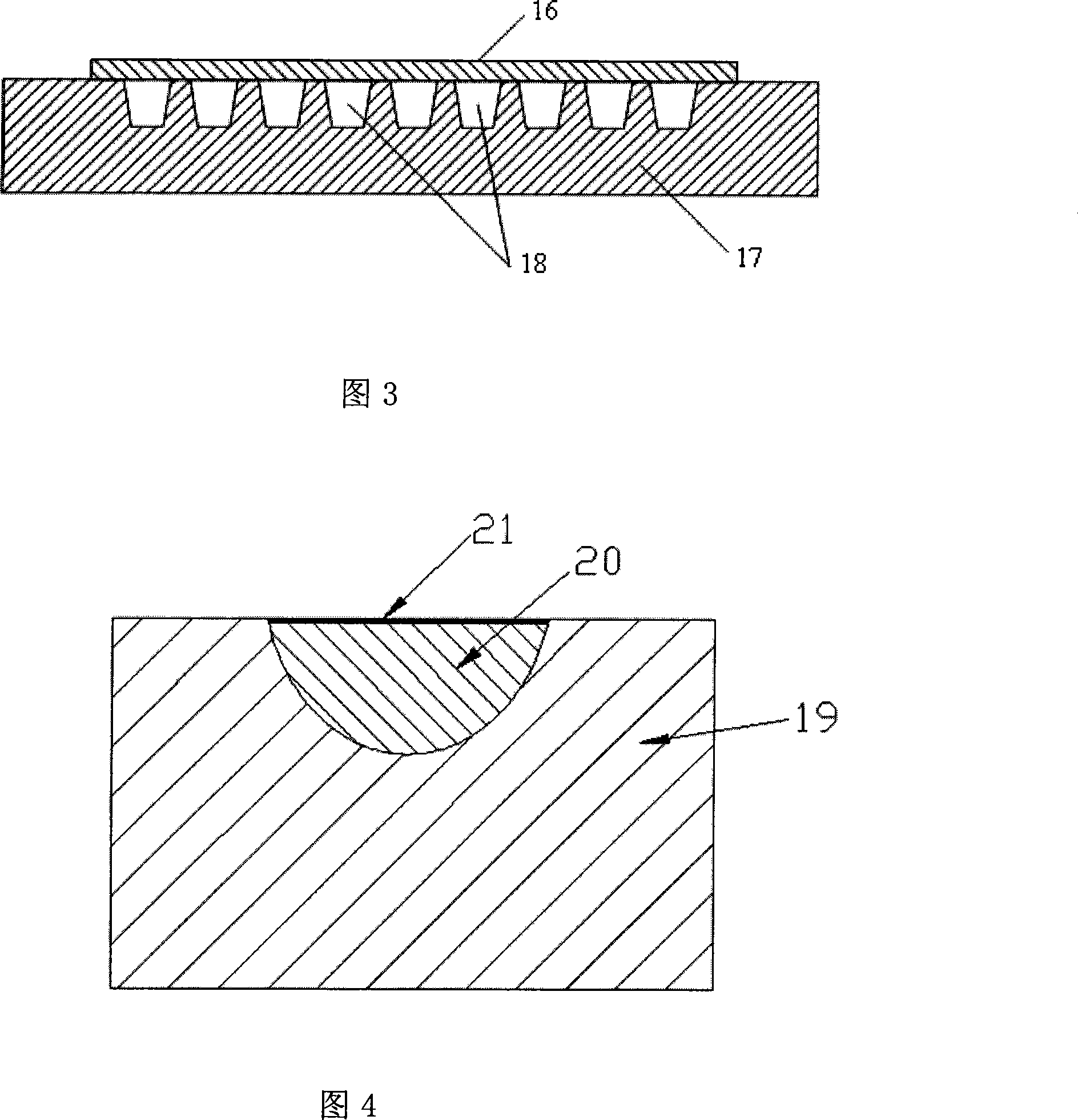

Method and equipment for waste and old mold electromagnetic weld deposit repair and surface modification

A surface modification and mold technology, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high deposition rate and low dilution rate, high toughness, low toughness and plasticity, and limited performance improvement. Achieve the effects of reducing the sensitivity of pores, improving toughness and plasticity, and improving crystallization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: Overlay welding H13 steel functional layer on the waste mold, its overlay welding process parameters are: pulse peak welding current: 350A, pulse base value welding current: 240A, pulse time: 8ms, shielding gas: 95% Ar+CO2 , Wire extension length: 20mmm, excitation current: 3A, excitation frequency: 5Hz, wire diameter: 1.2mm.

Embodiment 2

[0077] Example 2: Surfacing Ni-based and Cr-W-based gradient functional layers on No. 45 steel waste molds. The welding process parameters are: pulse peak welding current: 400A, pulse base value welding current: 260A, pulse time: 10ms , Shielding gas: 95% Ar+O2, wire extension length: 18mmm, excitation current: 2A, excitation frequency: 3Hz, wire diameter: 1.6mm.

[0078] According to the actual surfacing object and mold material composition, comprehensively consider the joint form, surfacing functional layer, surfacing material composition and surfacing process parameters, and systematically optimize the surfacing process to ensure high-quality surfacing remanufacturing mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Overhang | aaaaa | aaaaa |

| Overhang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com