Titanium and titanium alloy component arc welding adding material remanufacturing method

A remanufacturing, titanium alloy technology, applied in the field of remanufacturing engineering, can solve the problems of large heat input, low material utilization rate, poor gas protection regulation, etc., to achieve the effect of reducing heat input and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

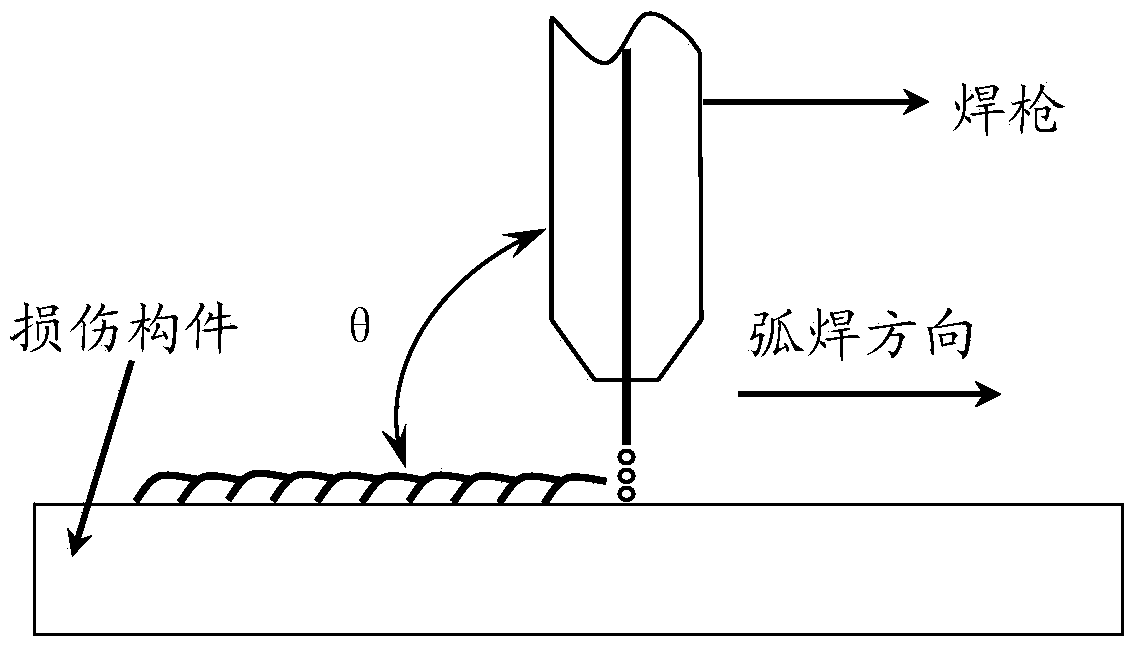

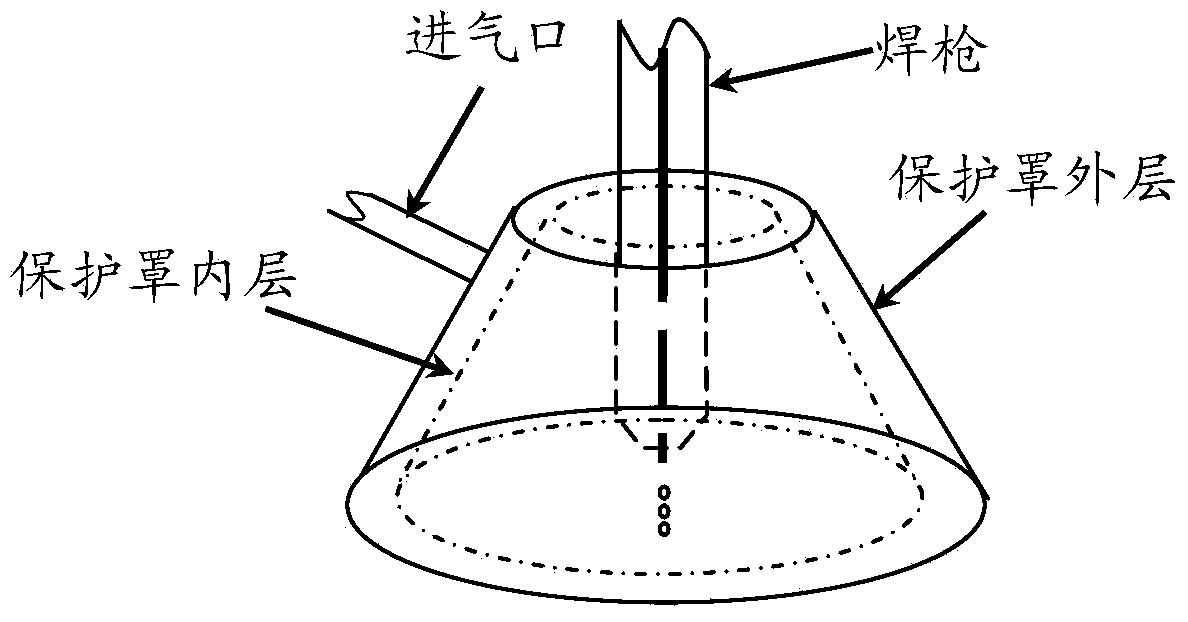

Embodiment 1

[0027] Using the invented titanium and titanium alloy arc welding additive remanufacturing method, the spot wear was repaired (the length of the maximum wear part is 10mm, and the depth is 1.1mm). The arc welding robot adopts the IRB2400 arc welding robot with a maximum load of 16kg and welding wire The grade is TC4, the diameter of the welding wire is 1.0mm, and the bell type gas shielding structure is adopted; the angle between the welding torch and the welding seam is 105°, the angle between the welding torch and the component substrate plane is 95°, the wire feeding speed is 12.0m / min, and the welding speed is 15mm / s, inductance correction +3%, arc length correction 2.6, the protective gas used in the micro-area of the molten pool is helium-argon mixed gas, the volume ratio of helium and argon is 9.5:0.5, the flow rate is 28L / min, the weld micro-area The protective gas used is argon-helium mixed gas, the volume ratio of argon to helium is 9.5:0.5, the flow rate is 35L / mi...

Embodiment 2

[0030]Using the invented titanium and titanium alloy arc welding additive remanufacturing method, the repair of linear wear (wear length 70mm, maximum wear width 3.0mm) is carried out. The arc welding robot adopts IRB2400 arc welding robot, the maximum load is 16kg, and the welding wire grade is TC4, the diameter of the welding wire is 1.2mm, and the boat-shaped gas shielding structure is adopted; the angle between the welding torch and the welding seam is 85°, the angle between the welding torch and the component substrate plane is 85°, the wire feeding speed is 6.5m / min, and the welding speed is 8mm / s. , inductance correction -3%, arc length correction -2.6, the protective gas used in the micro-area of the molten pool is helium-argon mixed gas, the volume ratio of helium and argon is 8.5:1.5, the flow rate is 22L / min, the weld micro-area The protective gas used is argon-helium mixed gas, the volume ratio of argon to helium is 9.0:1.0, the flow rate is 12L / min, the gas prote...

Embodiment 3

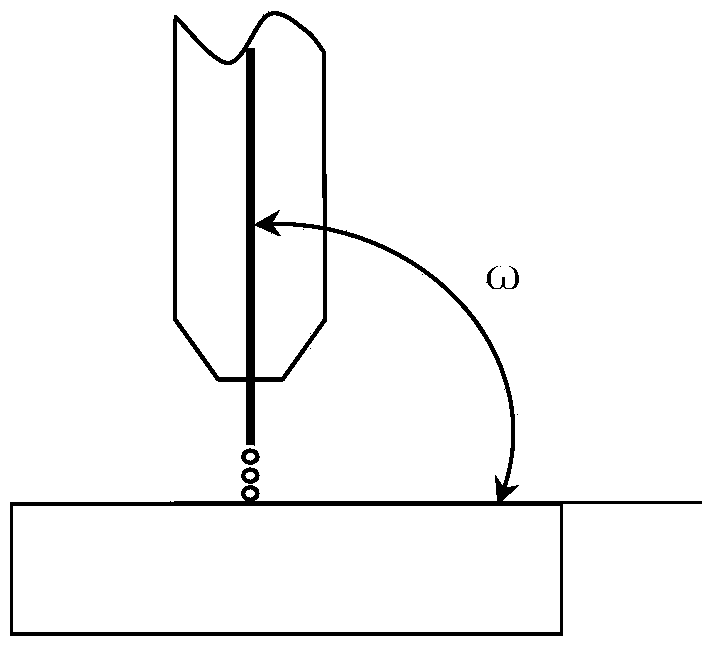

[0033] Using the invented titanium and titanium alloy arc welding additive remanufacturing method, the repair of arc-shaped wear (the maximum curvature radius is 15mm) is carried out. The arc welding robot adopts IRB2400 arc welding robot, the maximum load is 16kg, the welding wire grade is TC4, and the welding wire The diameter is 0.8mm, the bell type gas shielding structure is adopted, the angle between the welding torch and the welding seam is 95°, the angle between the welding torch and the component substrate plane is 95°, the wire feeding speed is 10m / min, the welding speed is 12mm / s, and the inductance correction is -3 %, the arc length correction is 2.6, the protective gas used in the molten pool micro-area is helium, the flow rate is 28L / min, the protective gas used in the weld micro-area is argon, the gas flow rate is 30L / min, the gas protection is started 10 seconds in advance, and then start Arc; keep the position of the torch unchanged after the arc is extinguished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com