Process cartridge remanufacturing method

一种处理盒、再制造的技术,应用在仪器、应用电荷图形的电记录工艺的设备、光学等方向,能够解决显影剂耗尽等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

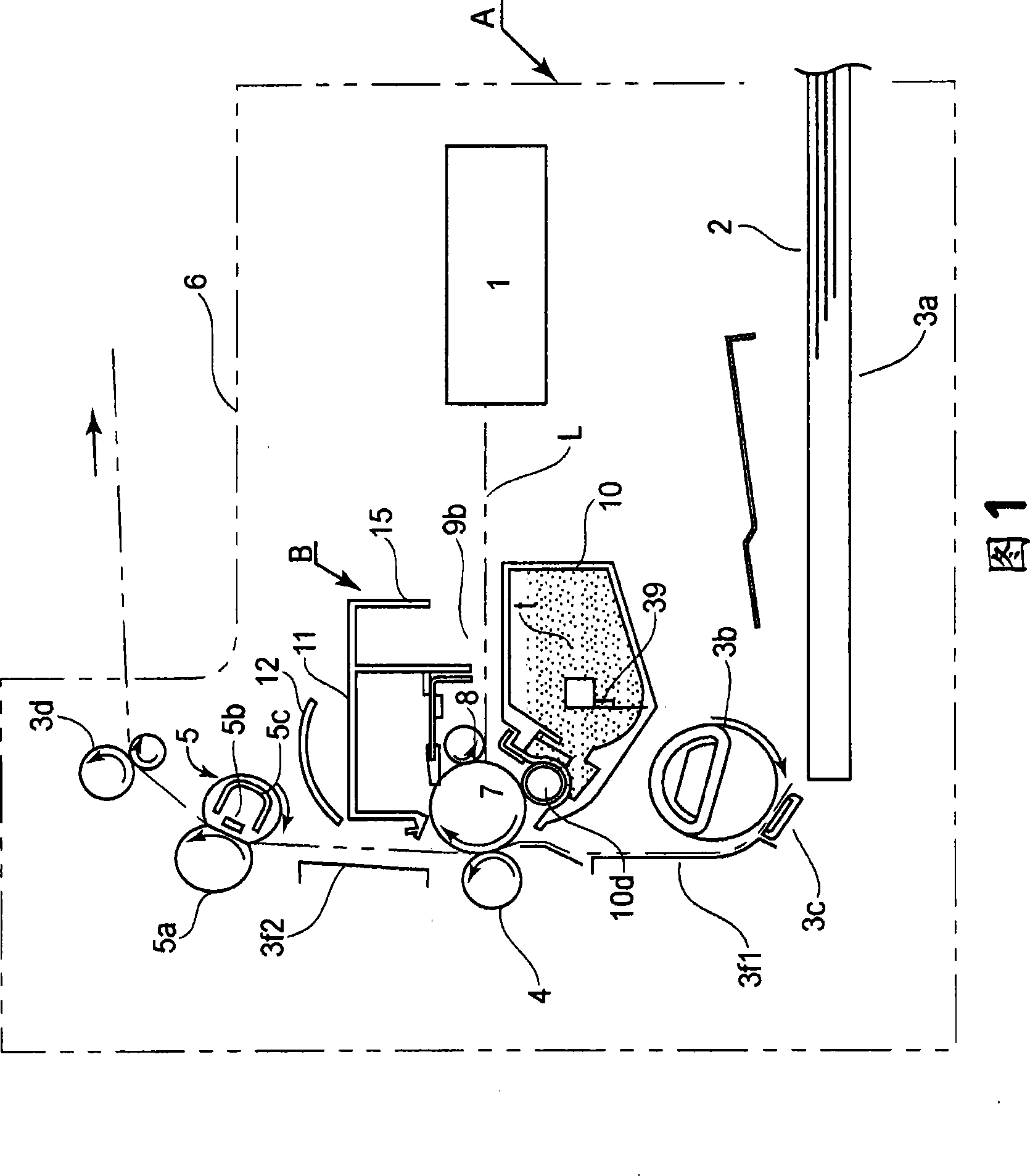

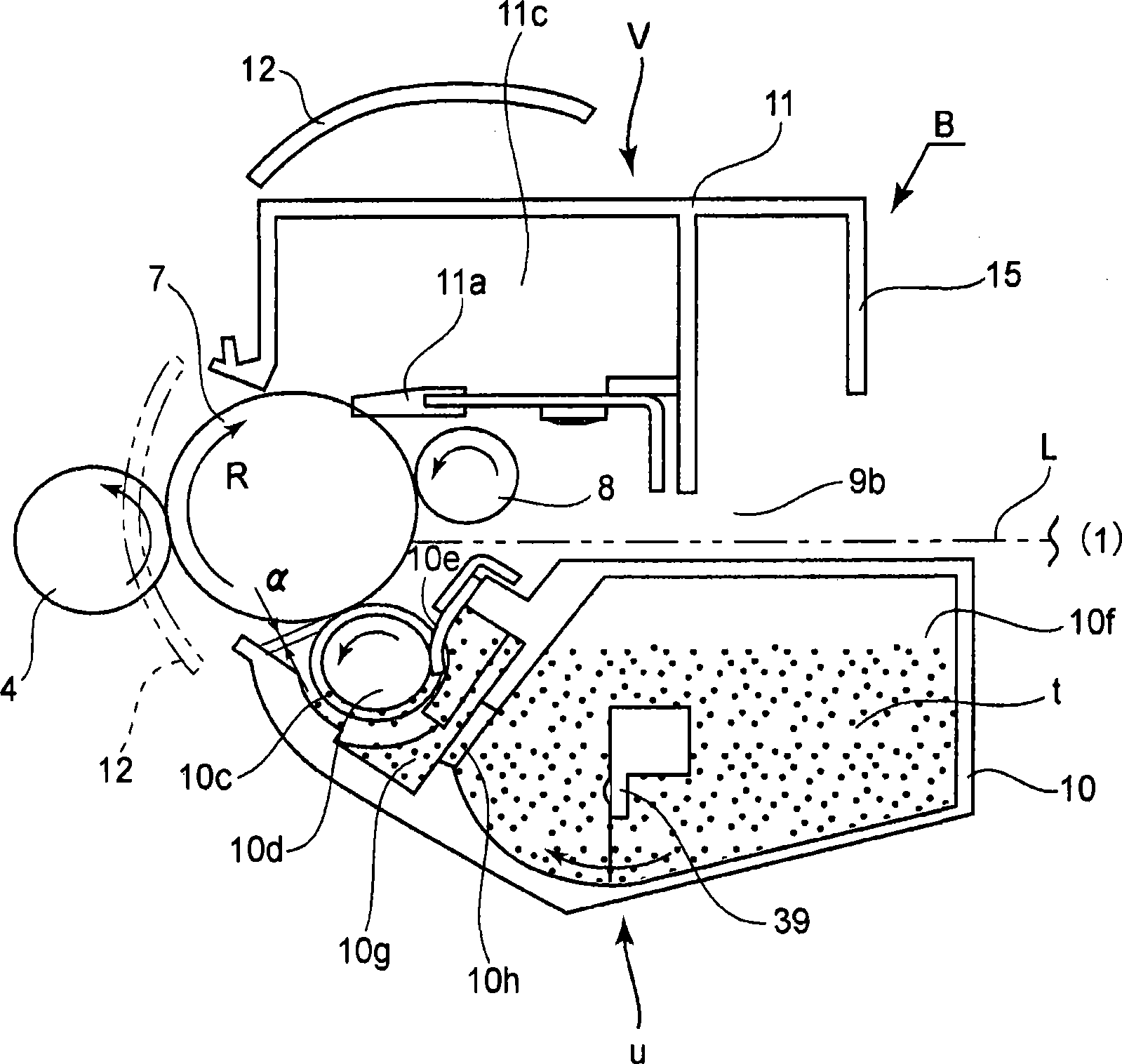

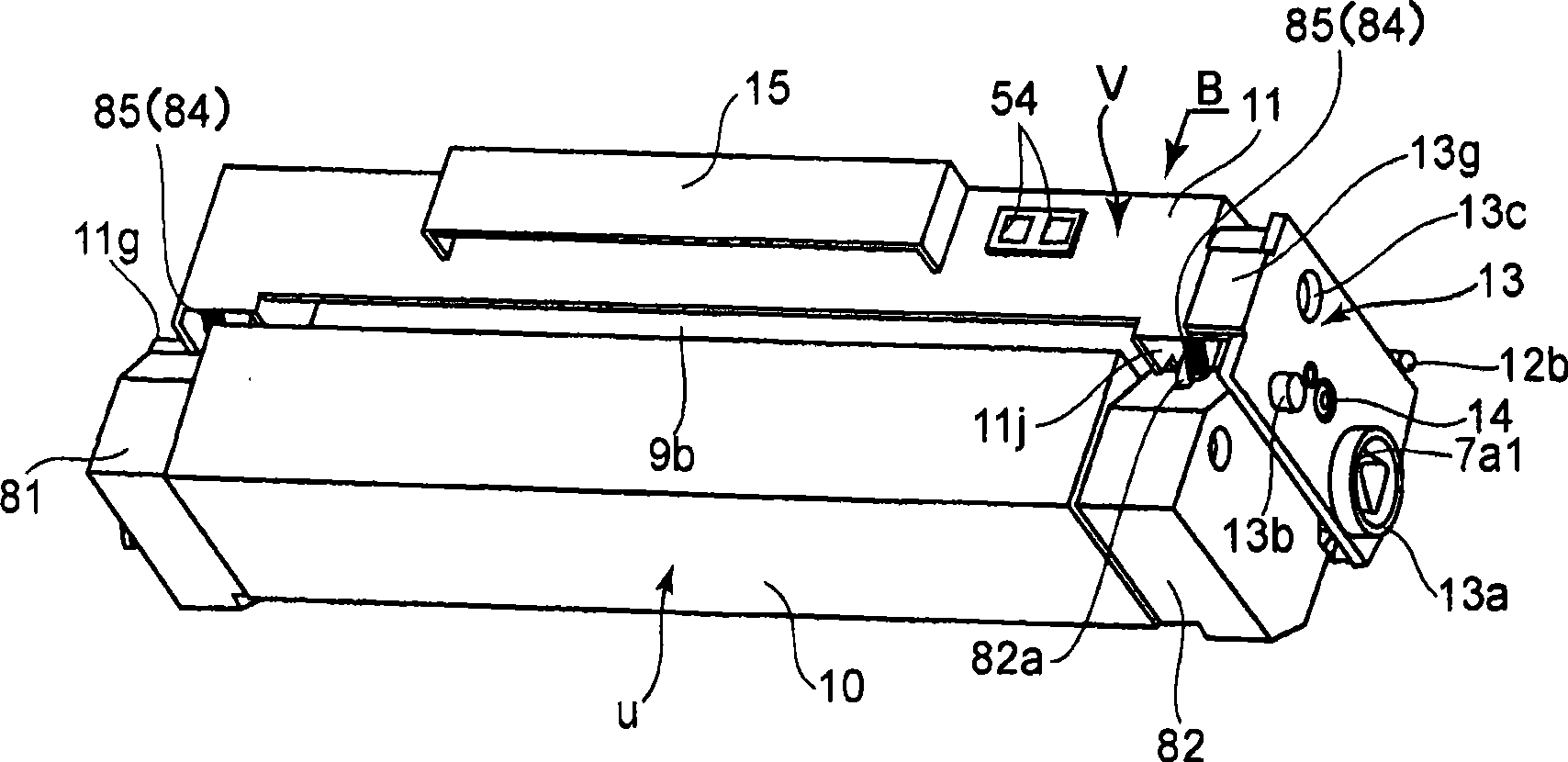

[0045] First, a process cartridge to which the process cartridge manufacturing method according to the present invention is preferably applied and an electrophotographic image forming apparatus in which the process cartridge is detachably mounted will be described with reference to the accompanying drawings.

[0046] (General Description of Electrophotographic Imaging Devices)

[0047] First, referring to FIGS. 1 and 2, the general structure of a typical electrophotographic image forming apparatus will be described. Fig. 1 is a schematic sectional view of an electrophotographic image forming apparatus after a process cartridge to which the present invention is applied is mounted in a main assembly A of the apparatus. figure 2 is an enlarged view of the process cartridge portion of FIG. 1. FIG.

[0048] In the following description of the preferred embodiments of the present invention, the process cartridge will be simply referred to as a cartridge. The main assembly of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com