Remanufacturing process of automobile aluminum alloy hub

A remanufacturing technology of aluminum alloy wheels, which is applied in the directions of wheels, vehicle parts, transportation and packaging, etc., can solve the problems of expensive materials of aluminum alloy wheels and hubs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

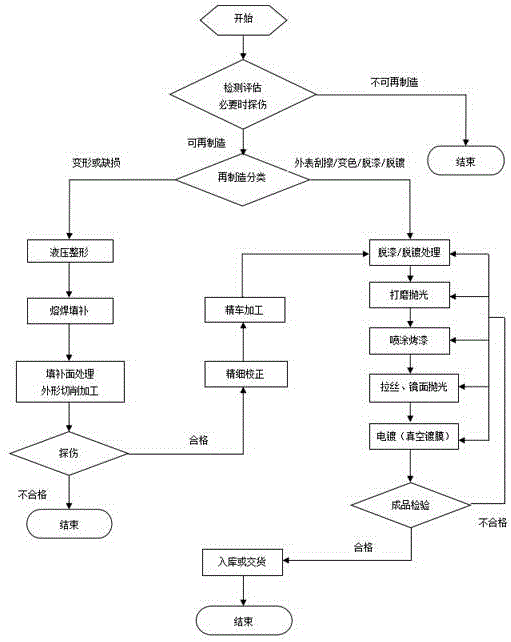

[0035] refer to figure 1 , the present invention proposes a kind of automobile aluminum alloy wheel hub remanufacturing process, comprises the following steps:

[0036] S1. Inspection and evaluation: Before remanufacturing the aluminum alloy wheel hub, it must be inspected and evaluated to determine whether the wheel hub has remanufacturing value; it can be divided into the following two situations:

[0037] 1) Damage condition

[0038] Any one of the following conditions shall be judged as having no remanufacturing value.

[0039] Spoke defects of the hub; cracks at the root of the spokes (flaw detection if necessary); the length of a single fracture at the protruding part of the wheel rim exceeds 50MM or more than 3 fractures and each fracture is greater than 20MM; other damages that are difficult to remanufacture.

[0040] 2) degree of deformation

[0041] Any one of the following conditions should also be judged as having no remanufacturing value.

[0042] The overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com