Flexible clamp based on phase-change material

A technology of phase-change materials and flexible fixtures, which is applied in clamping, manufacturing tools, workpiece clamping devices, etc., can solve problems such as difficult clamping of irregular-shaped parts, high quality requirements for combined components, and high-tech assembly and debugging requirements. The effects of long fixture life, simple structure, and easy remanufacturing and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

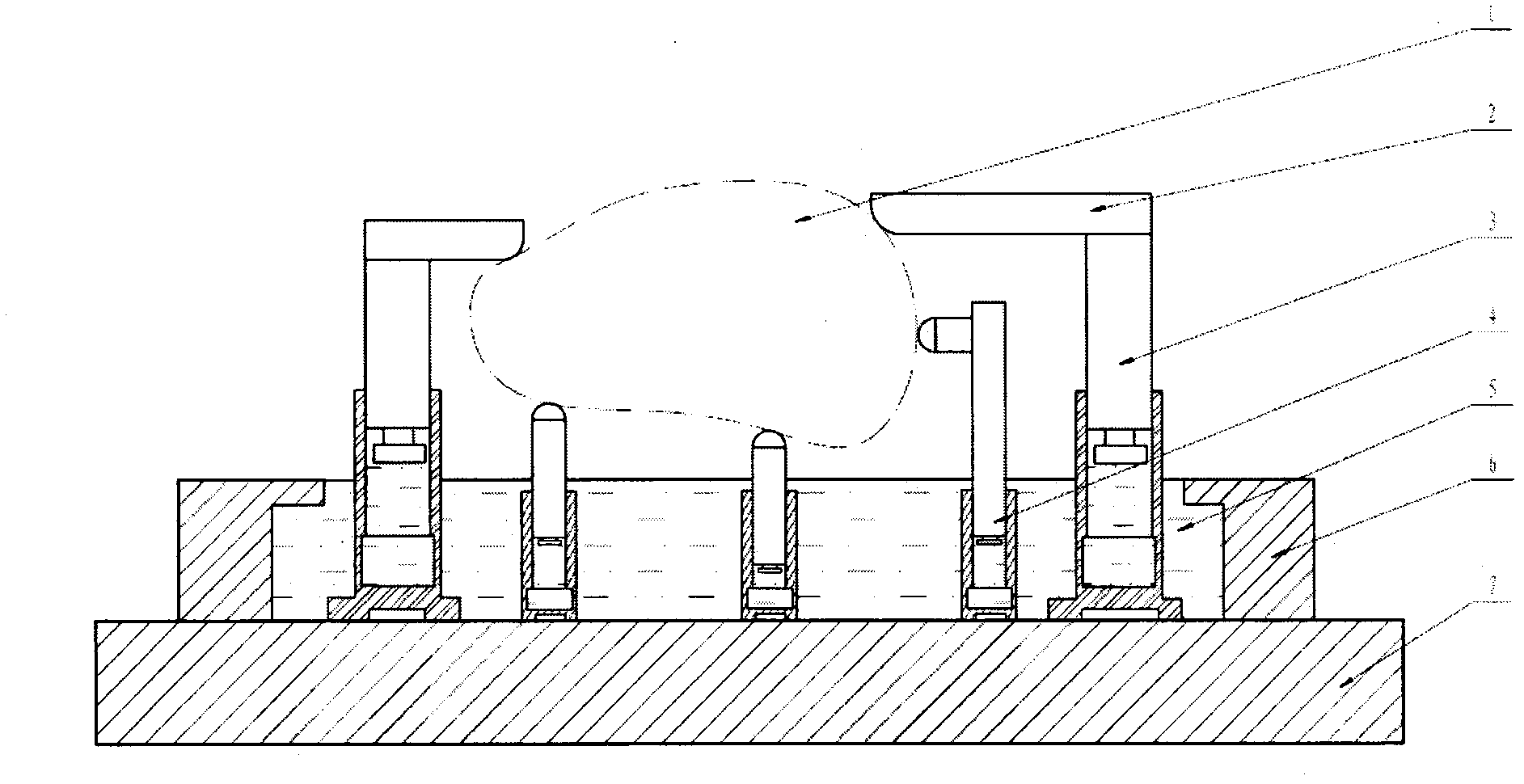

[0029] The first step is to determine the positioning position and clamping position according to the workpiece processing or assembly requirements, determine the adjustment length of each positioning body and clamping body, and determine the series of fixtures;

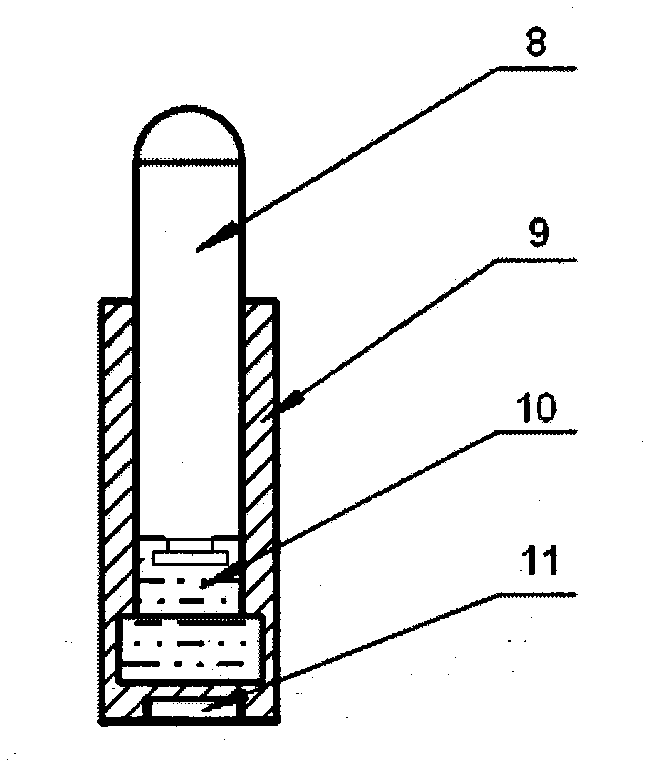

[0030] The second step is to adjust the special fixed-length tool to the required length, install the positioning head (8) into the positioning seat (9), put it into the tool, and inject the low melting point alloy phase change material (10) under pressure, and at the same time, the auxiliary The cooling device cools the phase change material, and takes out the positioning body (4) after cooling and solidification; the same method is used to make other positioning bodies;

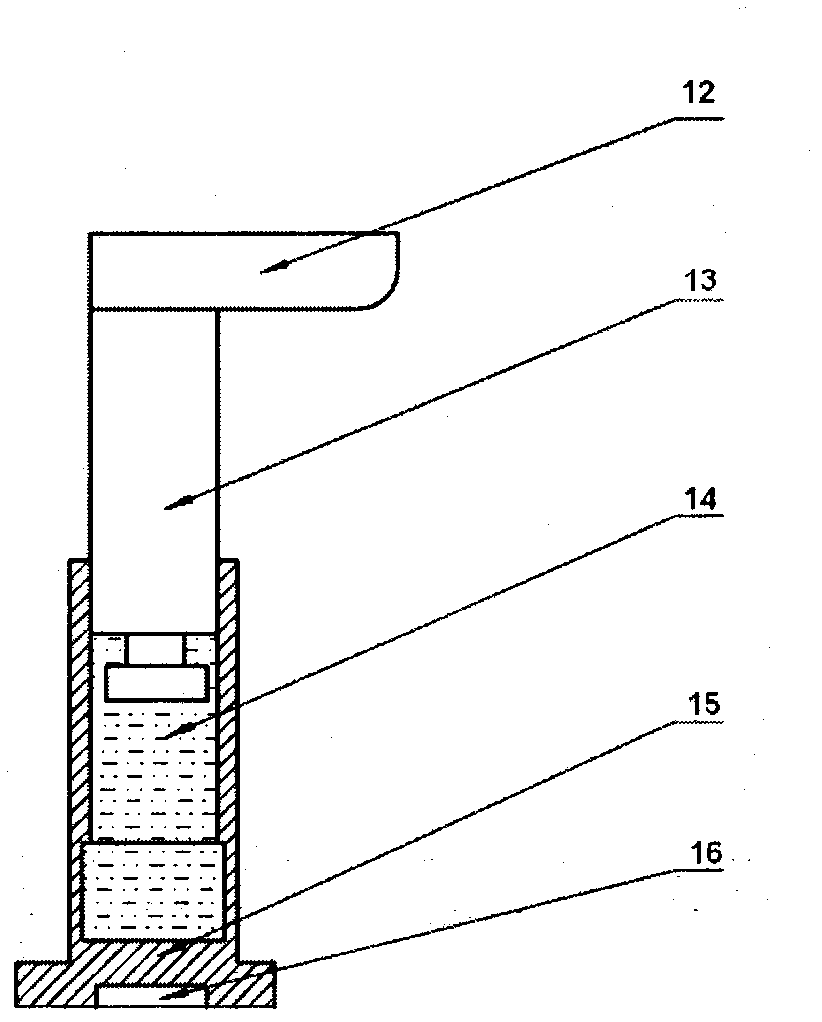

[0031] The third step is to adjust the special fixed-length tool to the required length of the clamping body, then install the clamping height adjustment body (13) into the clamping seat (15), then put it into the tool, and inject the melted low M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com