Normalization anneal treatment resistant heat-resistant steel wire solder and use method thereof

An annealing, heat-resistant steel technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of increasing welding material cost, production process, complex production process, etc., and achieve low cost and composition design. Simplicity, the effect of reducing material consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

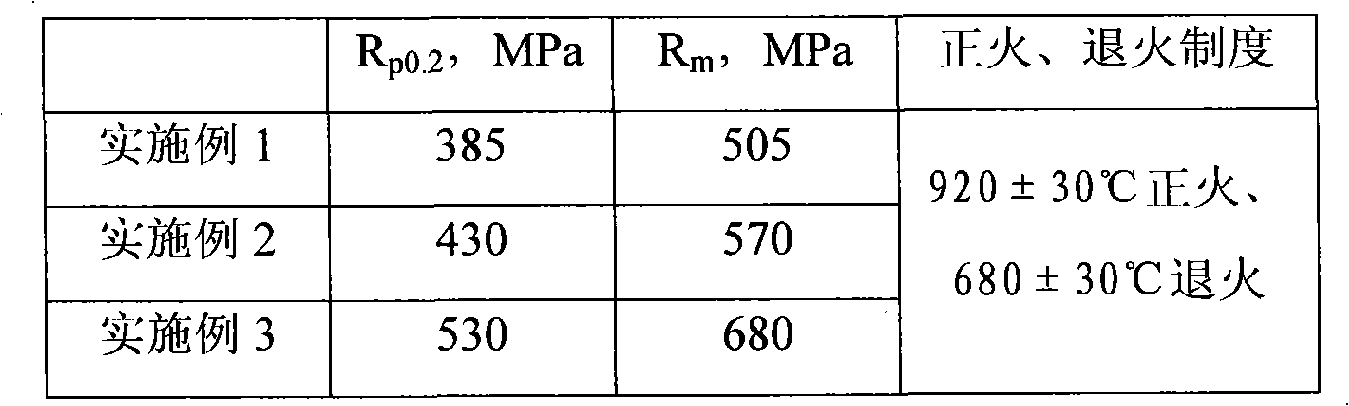

Examples

Embodiment Construction

[0035] The coating composition of the present invention is listed in Table 5. The diameter of the welding core H08A or H08E is Φ4mm.

[0036] Table 5: Drug skin composition by weight

[0037]

Dali

stone

ferro-titanium

Medium carbon ferromanganese

iron

iron

Soda ash

water

Glass

glass

Example 1

40

20

6.5

11

3

3

2.5

4.5

1.5

2

3

Example 2

45

19.5

7

12

5

2.5

3

6

1.0

2

0

Example 3

60

18

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com