Flux-cored wire for nickel base alloy

A technology of flux-cored welding wire and nickel-based alloys, which is applied to welding media, welding equipment, metal processing equipment, etc., and can solve problems such as welding process deviation and poor stability of weld performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

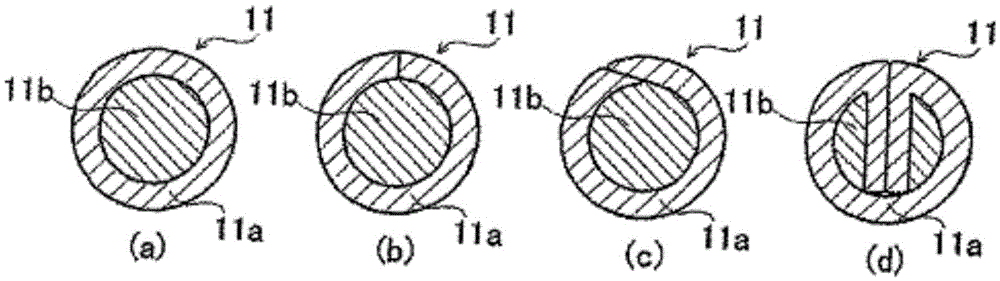

Image

Examples

Embodiment 1

[0069] Embodiment 1: Preparation of flux-cored welding wire of the present invention

[0070] The core powder is filled in the nickel-based alloy steel strip with a filling rate of 18%, and the mass percentage of the contained core powder is as follows: 10% metal chromium powder, 35% metal nickel powder, 1.5% metal manganese powder, 17% rutile, 2% ferrosilicon, 1% ferrotitanium, 6% feldspar, 5% quartz, 2% rare earth fluoride, 1% cryolite, 7% ferroniobium metal powder, 7% % metal ferromolybdenum powder, 3% calcium fluoride, and the rest is iron powder. After rolling, the flux-cored wire is welded with various shielding gases (100% CO2 gas, 80% Ar+20% CO2 mixed gas, and 100% Ar gas have the same welding effect, and the following others The embodiments are all the same), the chemical composition of the deposited metal after the welding of the welding wire is (main components, in parts by weight, which may also include traces of unavoidable impurities; the following embodiments...

Embodiment 2

[0072] Embodiment 2: Preparation of the flux-cored welding wire of the present invention

[0073] The drug core powder is filled in the nickel-based alloy steel strip with a filling rate of 20%, and the composition of the contained drug core mass percentage is as follows: 9% metal chromium powder, 36% metal nickel powder, 1% metal manganese powder, 17% rutile, 1% ferrosilicon, 0.5% ferrotitanium, 3% feldspar, 3% quartz, 1% rare earth fluoride, 2% cryolite, 5% ferroniobium metal powder, 6 % metal ferromolybdenum powder, 2% calcium fluoride, and the rest is iron powder. After rolling, the flux-cored wire is welded with a variety of shielding gases. The chemical composition of the deposited metal after welding is: C: 0.049, Si: 0.36, Mn: 0.27, P: 0.005, S: 0.008, Ni: 63.44, Cr: 20.34, Nb: 3.35, Mo: 8.29, Cu: 0.009, Fe: 2.85, Ti: 0.094, Co: 0.009, the weld formed by it is beautiful in appearance, and the properties of the weld metal are excellent; Seam metal has strong high te...

Embodiment 3

[0074] Embodiment 3: Preparation of flux-cored welding wire of the present invention

[0075] The drug core powder is filled in the nickel-based alloy steel strip with a filling rate of 19%, and the mass percentage of the contained drug core is as follows: 11% metal chromium powder, 34% metal nickel powder, 2.5% metal manganese powder, 16% rutile, 3% ferrosilicon, 2% ferrotitanium, 4% feldspar, 4% quartz, 1.5% rare earth fluoride, 3% cryolite, 6% ferroniobium metal powder, 8 % metal ferromolybdenum powder, 1% calcium fluoride, and the rest is iron powder. After rolling, the flux-cored wire is welded with a variety of shielding gases. The chemical composition of the deposited metal after welding is: C: 0.047, Si: 0.42, Mn: 0.30, P: 0.006, S: 0.009, Ni: 63.23, Cr: 20.94, Nb: 3.38, Mo: 8.49, Cu: 0.006, Fe: 2.87, Ti: 0.085, Co: 0.006, the weld formed by it is beautiful in appearance, and the properties of the weld metal are excellent; Seam metal has strong high temperature res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com