Method for rapidly detecting micro-structure three-dimensional dimension stereoscopic picture

A three-dimensional, three-dimensional image technology, applied in image data processing, measuring devices, instruments, etc., can solve the problems of complex operation process, low detection resolution and accuracy, and influence of detection accuracy, so as to ensure measurement accuracy and simple operation process. , the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

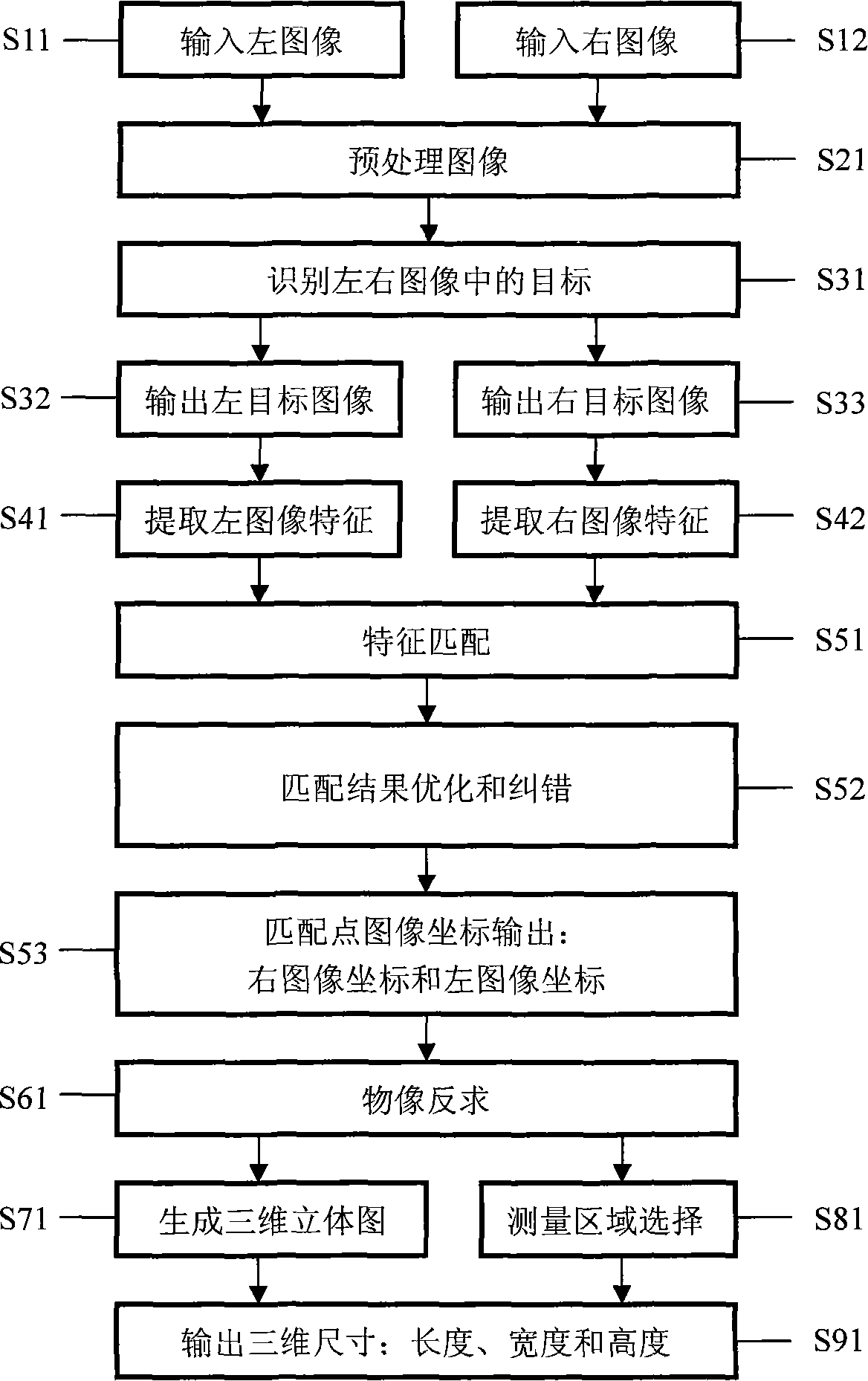

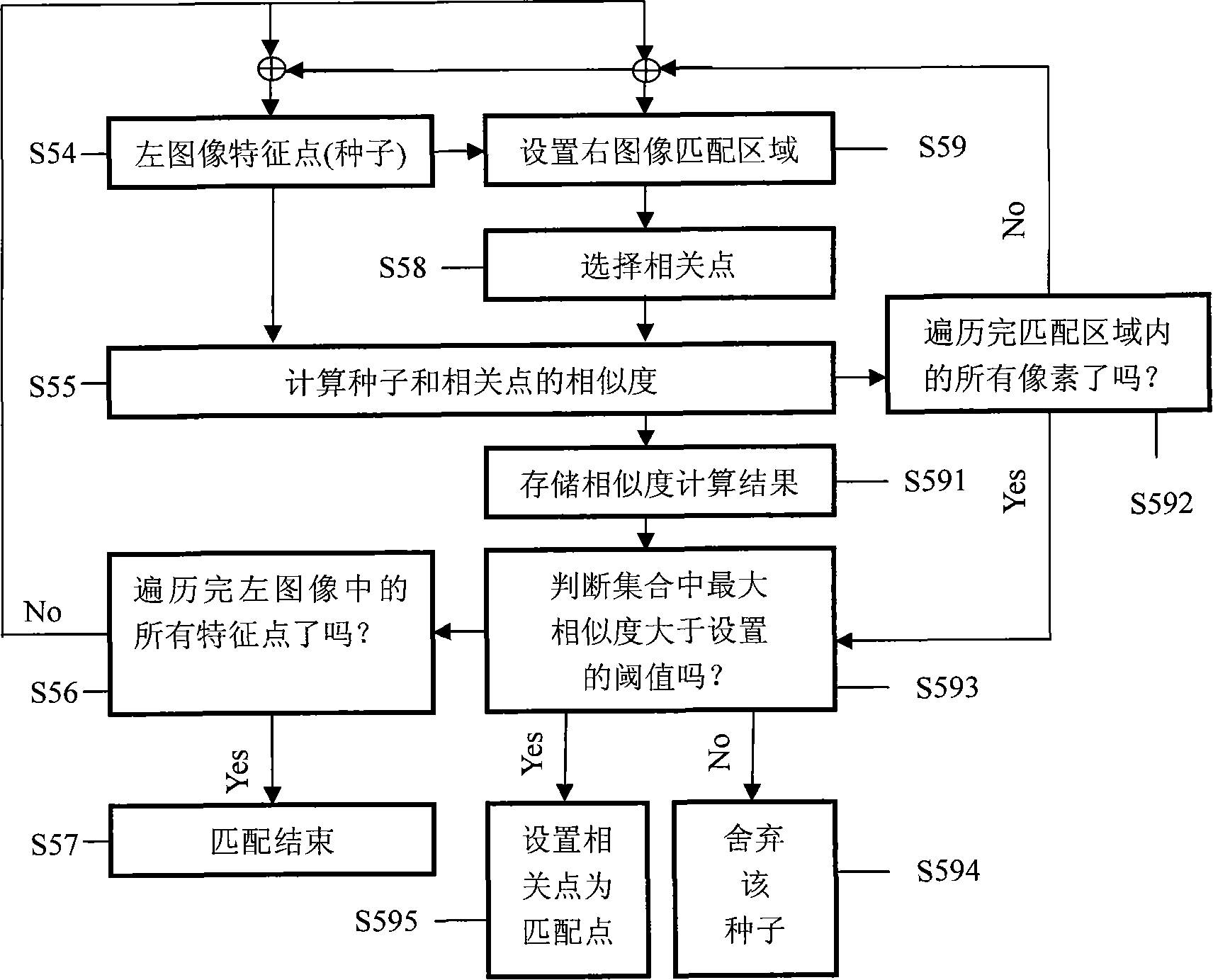

[0053] The present invention is described in further detail now in conjunction with accompanying drawing. figure 1 and figure 2 A flow chart showing the rapid detection method for three-dimensional stereoscopic images of microstructures involved in the present invention, as shown in the figure, the rapid detection method for three-dimensional stereoscopic images of microstructures includes the following steps:

[0054] 1. Preprocess the image

[0055] The left image S11 and the right image S12 are input to the computer, and the color image vector median filter method is used for filtering to obtain filtered color images IAL and IAR. Then use the following method to segment the target and the image background for the color image.

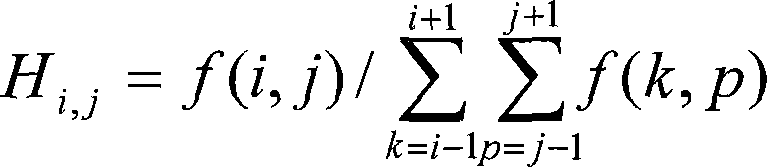

[0056](1) For all pixels in the entire color image IAL(IAR), convert the image IAL(IAR) into a grayscale image IBL(IBR). The conversion method is: the red, green and blue gray values of the pixels in the grayscale image IBL (IBR) are equal, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com