Large-sized forgeable piece three-dimensional size and temperature on-line detection device

A technology for large forgings and detection devices, applied in measuring devices, optical devices, radiation pyrometry, etc., can solve problems such as the inability to reflect the three-dimensional shape information of large forgings, and achieve elimination of luminous and high temperature effects, high structural rigidity, and scanning. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

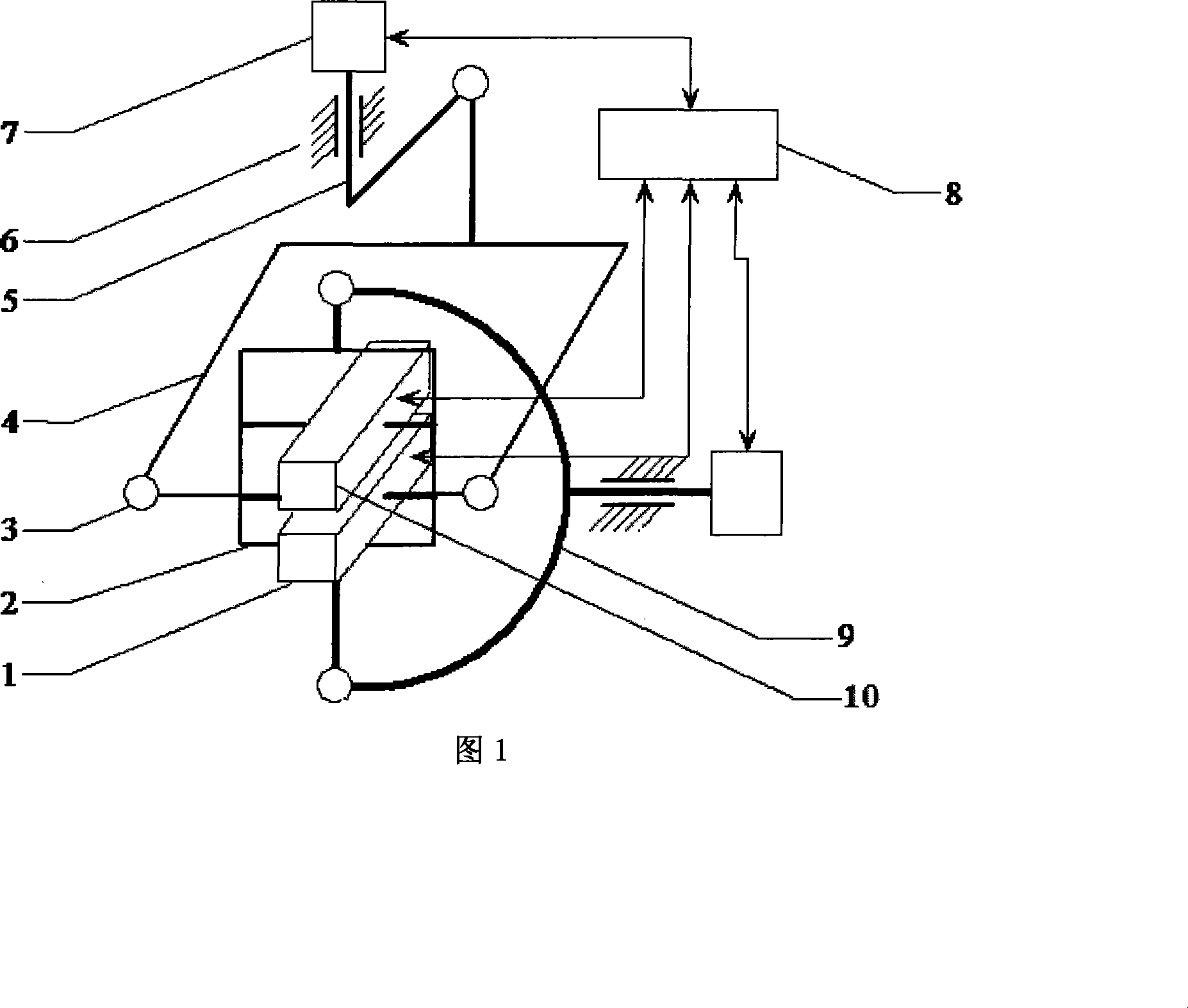

[0014] The structure of the large-scale forging three-dimensional external dimension and temperature online detection device of the present invention is shown in Figure 1, mainly including a high-temperature laser rangefinder 1, an infrared thermometer 10 and a computer 8, and adopts a two-degree-of-freedom parallel rotating scanning frame to realize three-dimensional Scan measurement. The two-degree-of-freedom parallel rotating scanning frame consists of a motion platform 2, five hinges 3, an outer frame 4, a driving rod 5, a frame 6, two motors 7 and an inner frame 9 One group of opposite sides of the moving platform 2 is connected with the inner frame 9 through two hinges 3, the inner frame 9 is connected with a motor 7 and installed on the frame 6 of the motor, the other pair of the moving platform 2 Limit is connected with oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com