Side-by-side package separating device and method

A separation method and separation device technology, applied in the direction of transportation and packaging, sorting, conveyor objects, etc., can solve problems such as unresolved identification and subsequent separation and disposal, difficulty in meeting on-site processing requirements, unfavorable single code scanning, etc., to achieve reduction The effect of manual input, reduction of operation intensity and workload, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

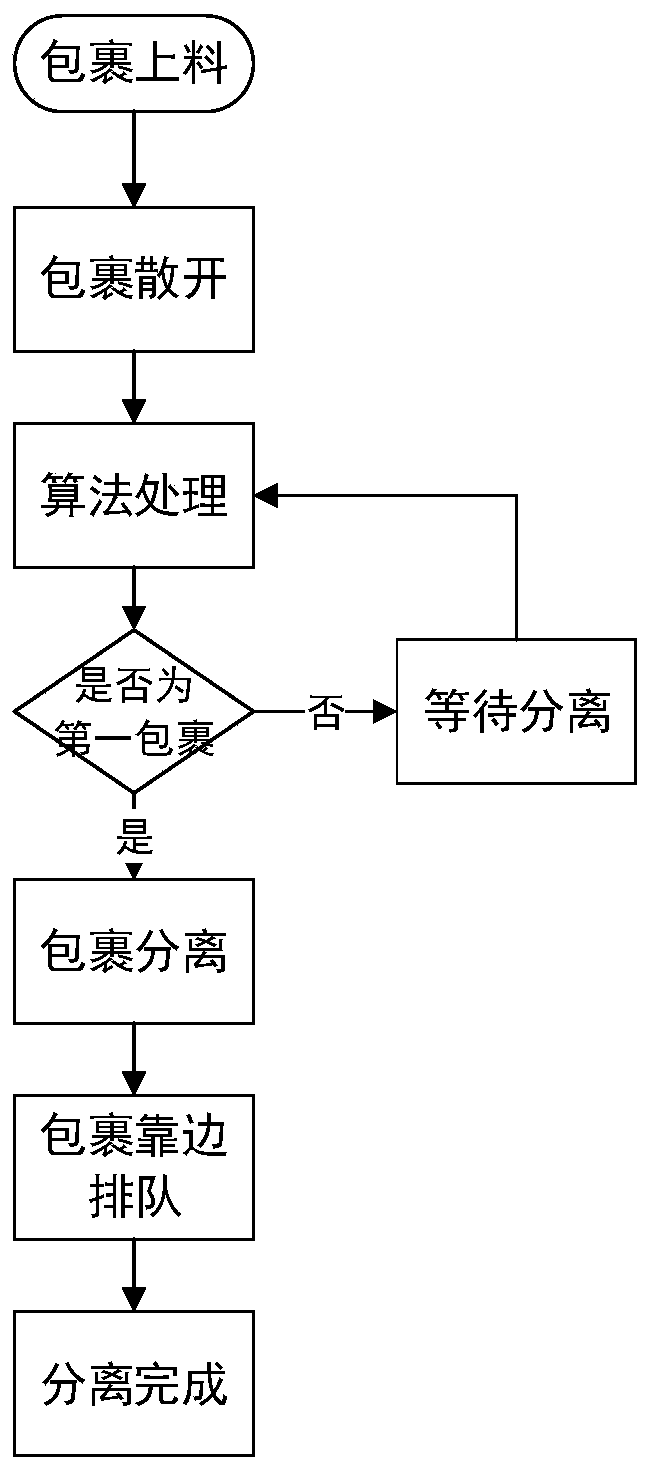

[0047] Embodiment 1, the separation method of side-by-side parcels described in this application, includes the following implementation steps:

[0048] 1) scattered

[0049] The parcels arriving at the dispersing device from the conveying line are dispersed through the angle difference in the conveying direction, leaving gaps between adjacent parcels;

[0050] 2) Detection and identification

[0051] The visual identification device is installed along the vertical direction of the package delivery direction, and the visual identification device includes a 3D camera;

[0052] Take photos and identify the detected packages through the visual recognition device, and obtain the three-dimensional size and real-time location data of each package;

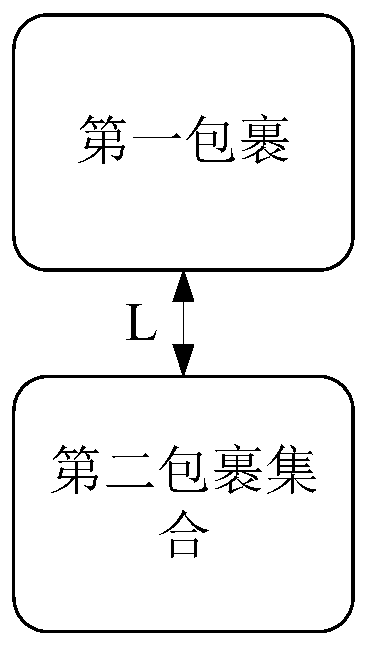

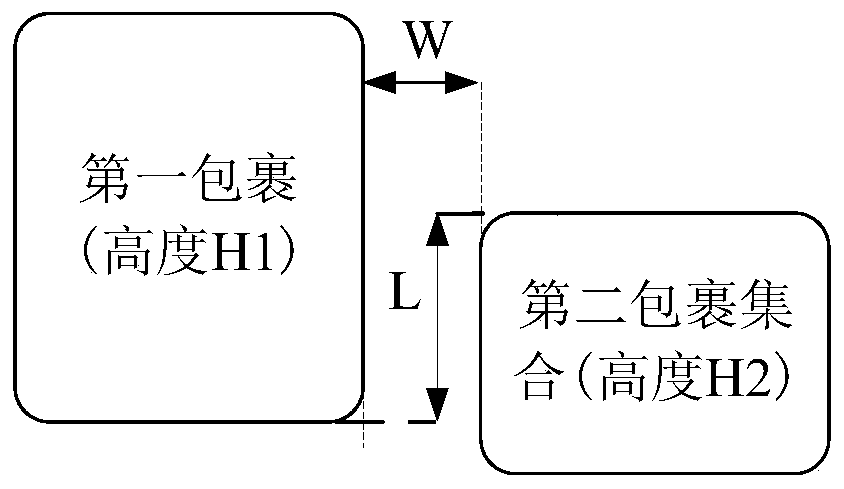

[0053] The visual recognition device performs edge detection on the package image according to the image recognition algorithm, and screens out the three-dimensional coordinates and position information of the package corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com