Nut shell breaking and screening equipment for food processing

A technology of food processing and screening equipment, which is applied in the directions of filtering, shelling, application, etc., which can solve the problems of low work efficiency, time-consuming and labor-intensive cracking of nut shells, etc., and achieve the effect of improving work efficiency and facilitating collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

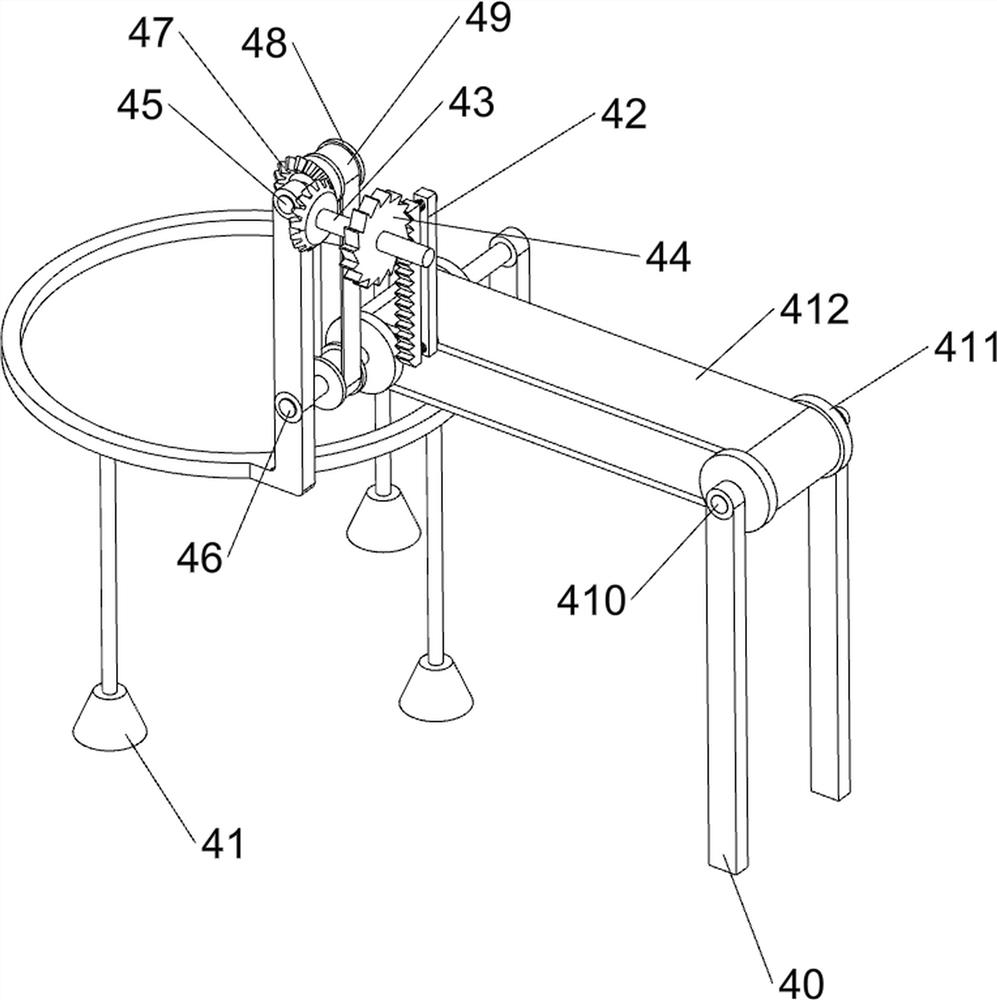

[0025] A kind of nut shell screening equipment for food processing, such as figure 1 , figure 2 and image 3 As shown, it includes a base plate 1, a servo motor 2, a shell breaking mechanism 3 and a transmission mechanism 4. A servo motor 2 is provided at the rear of the top left side of the base plate 1, and a breaker is provided between the top left side of the base plate 1 and the output shaft of the servo motor 2. The shell mechanism 3 is provided with a transmission mechanism 4 on the left side of the top of the bottom plate 1. The shell breaking mechanism 3 includes a first support rod 30, a first rotating shaft 31, a second rotating shaft 32, a first bevel gear 33, a turntable 34, and a connecting rod 35 and extruding rod 36, the front and rear sides of base plate 1 top left side are all provided with first support rod 30, and the first support rod 30 top of rear side is provided with the first rotating shaft 31 in rotation, on the output shaft of servo motor 2 There...

Embodiment 2

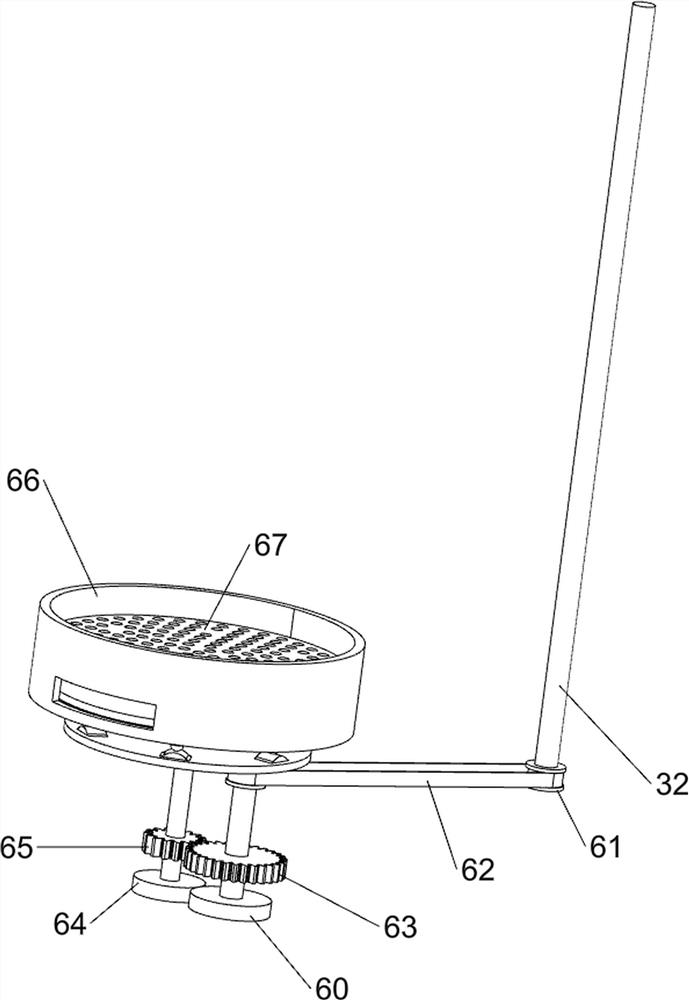

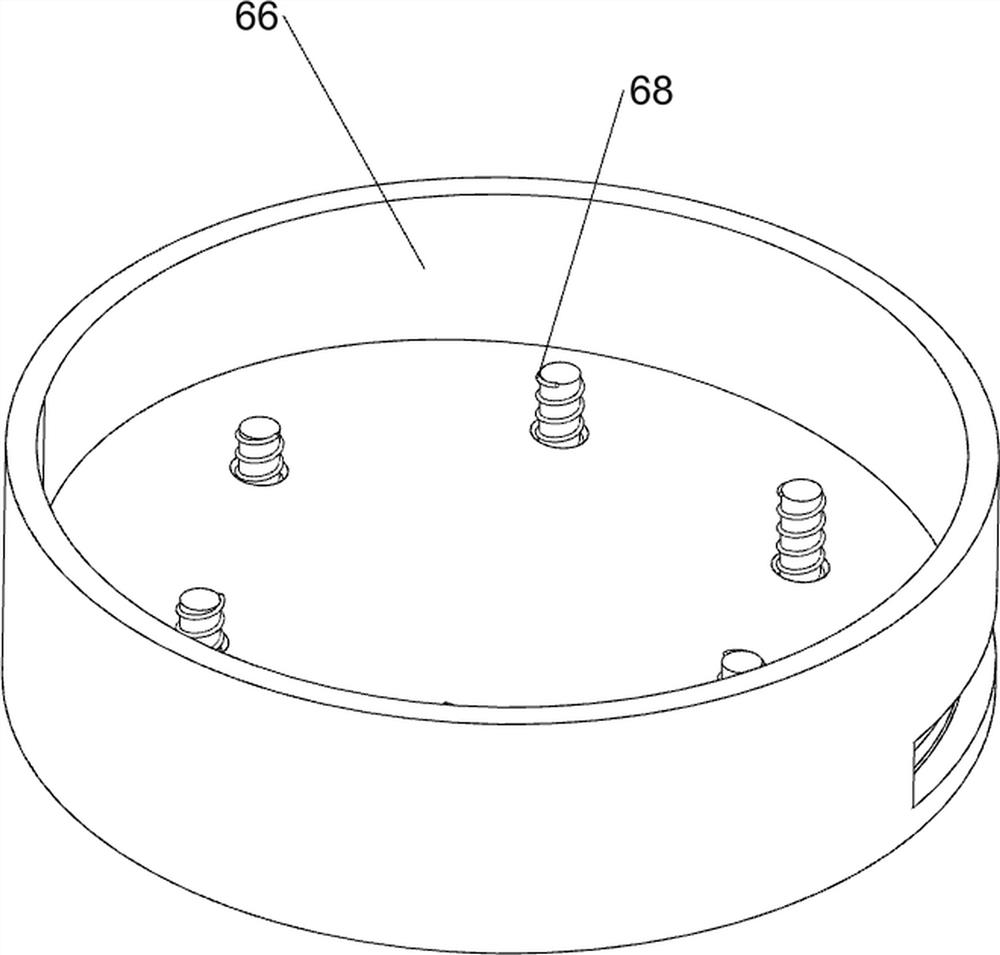

[0029] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, also includes feeding mechanism 5, and feeding mechanism 5 includes the 4th support rod 50, support block 51, the 3rd bevel gear 52, the 7th rotating shaft 53, the 3rd roller 54, the 3rd belt 55, cam 56. Top block 57, first spring 58 and lower hopper 59, bottom plate 1 top left front part is rotatably provided with fourth support rod 50, and the fourth support rod 50 rotates between the middle part of first support rod 30 on the front side There is a supporting block 51 in the formula, the third bevel gear 52 is provided on the front side of the sixth rotating shaft 410 and the upper part of the fourth supporting rod 50, and the third bevel gears 52 are meshed with each other. Rotating shaft 53, the middle part of the seventh rotating shaft 53 and the top of the fourth support rod 50 are provided with a third roller 54, a third belt 55 is wound between the third rollers 54, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com