High-strength collagen gel and preparation method thereof

A technology of collagen gel and collagen hydrogel, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, non-effective ingredients of polymer compounds, etc., and can solve biological safety hazards, collagen denaturation, and low mechanical strength of gels, etc. problem, achieve good compatibility, high degree of cross-linking, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

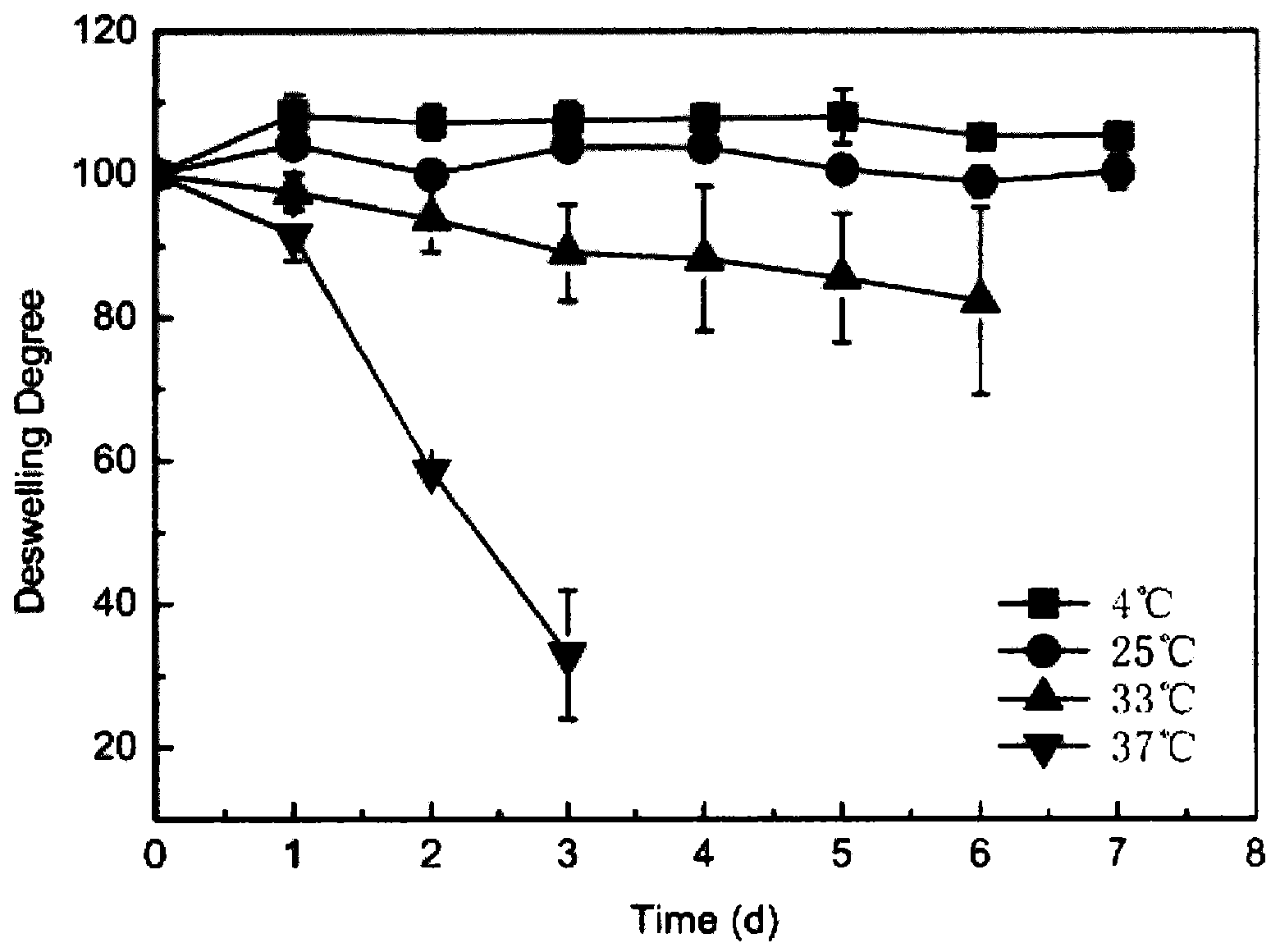

Embodiment 1

[0035] The collagen aqueous solution with a solid content of about 10% is injected into a specific mold, sealed after removing air bubbles, and irradiated with a high-energy electron beam of 25kGy to obtain an initial hydrogel with a compression modulus of 0.3MPa. When the hydrogel was immersed in water at 37°C, the gel would shrink by 40% in 24 hours, and the compressive modulus was 0.8MPa, which was 2.67 times that of the initial hydrogel; in 72 hours, the gel would shrink by 80%, and the compressive modulus was 1.5MPa, which increased to 5 times the size of the initial hydrogel.

Embodiment 2

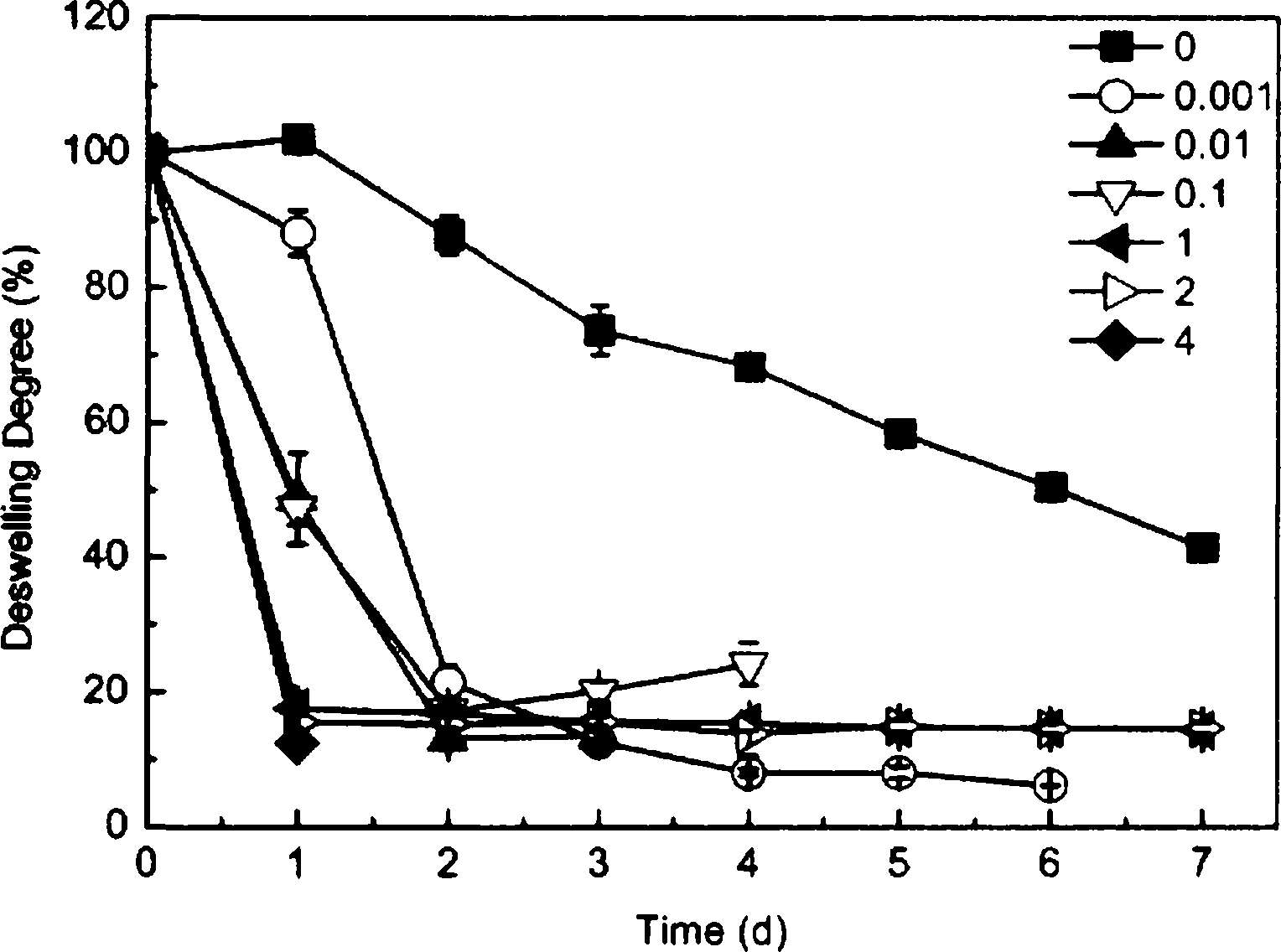

[0037] Inject an aqueous collagen solution with a solid content of about 0.3% into the mold, defoam and seal it, and use 60 Coγ-rays were irradiated with 5kGy to obtain an initial hydrogel with a compressive modulus of 0.02MPa. The gel is placed in a phosphate buffer solution at a constant temperature of 37° C. for 24 hours, that is, the shrinkage exceeds 80%, and the compressive modulus increases to 0.06 MPa, which is 3 times that of the initial hydrogel.

Embodiment 3

[0039] Aqueous collagen (solid content about 5%) and hyaluronic acid aqueous solution are made into a blend solution with a total mass fraction of 3% according to the collagen / hyaluronic acid mass ratio of 98 / 2 (ultrasonic dispersion of tricalcium phosphate β-TCP), and the mixer is fully stirred , to remove air bubbles and inject into a specific mold, and irradiate 10kGy with electron beam quickly after sealing to obtain a ternary composite hydrogel. Put an electric heating ring (37°C) of appropriate size or a ring with warm water circulating in the center of the gel, keep the temperature for a period of time to induce the middle of the gel to shrink, and obtain a dumbbell-shaped material, which can be used as a tangible scaffold for bone tissue engineering and cultivate bone marrow Stromal cells are used in bone defect repair.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com