In-situ detection device and method for flatness of ultra-precision grinding large-diameter optical components

A technology of optical components and detection methods, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as unsatisfactory measurement accuracy, achieve the effects of avoiding repeated processing, suppressing environmental errors, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

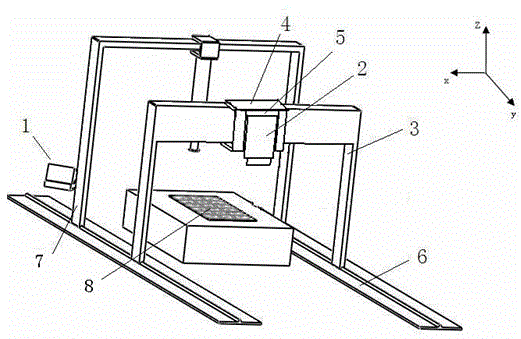

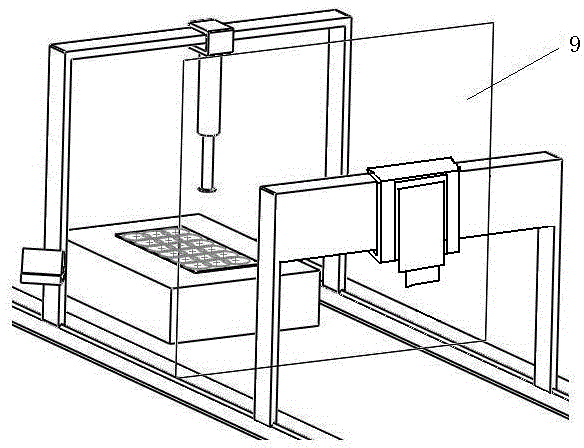

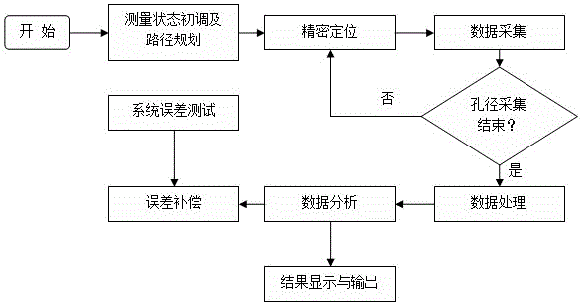

[0030] see figure 1 , an ultra-precision grinding large-caliber optical element flatness in-position detection device, including a computer 1, a dynamic interferometer 2, a main measurement stand 3, an x-direction guide rail 4, a z-direction guide rail 5, a stand guide rail 6, and an isolation device 9. The dynamic interferometer 2 is installed on the guide rail 5 in the z direction, and is used to measure each sub-aperture data of the measured surface 8, which is transmitted to the computer 1 for processing, and the main mirror of the dynamic interferometer 2 is provided with a closed cover; The main measurement platform 3 is an independent movable gantry structure, which moves along the platform guide rail 6, and the x-direction guide rail 4 and the z-direction guide rail 5 for moving the dynamic interferometer 2 horizontally are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com