An In-Situ Detection Method of Inner Cavity Surface Roughness Based on Two-point Rotational Friction

A technology of surface roughness and rotational friction, applied in mechanical roughness/irregularity measurement, electrical/magnetic roughness/irregularity measurement, electromagnetic measurement device, etc. High requirements and other problems, to achieve the effect of simple structure, low cost and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

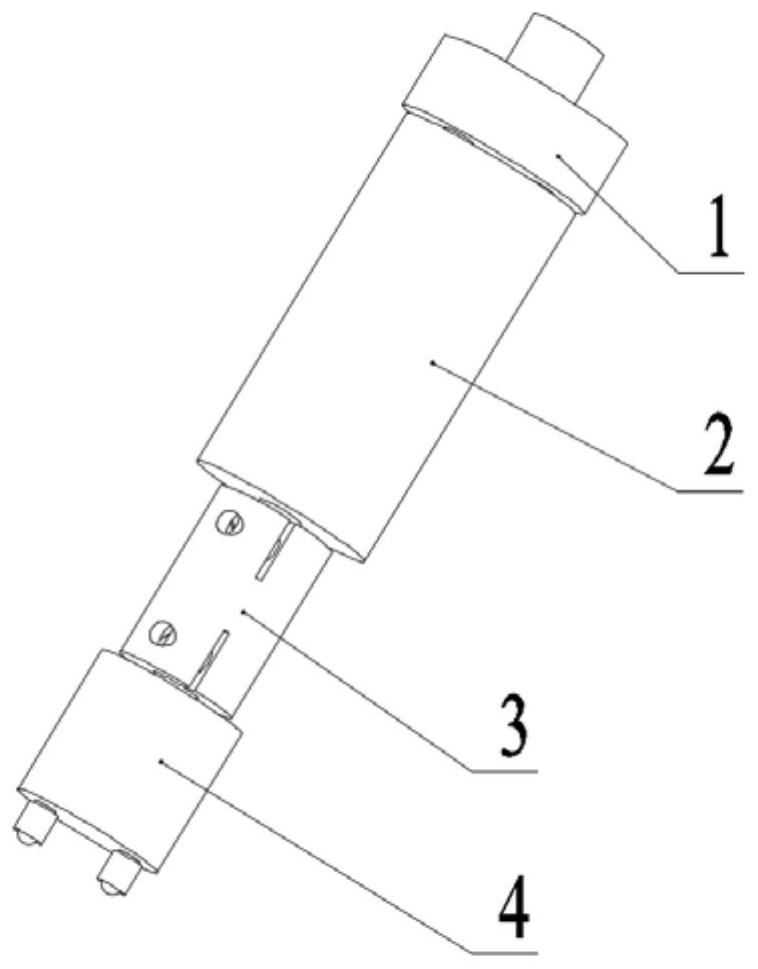

[0046] like figure 1 , 2 As shown, an in-situ detection method for the surface roughness of the inner cavity based on two-point rotating friction uses a finger probe for measurement, and the finger probe includes a pressure sensor 1, a miniature brushless DC motor 2, an elastic coupling 3. Friction assembly 4. DC power supply and oscilloscope.

[0047] The pressure sensor 1 is connected between the miniature brushless DC motor 2 and the mechanical arm by screwing, so as to realize the monitoring of the normal pressure of the friction assembly 4 .

[0048] The diameter of the miniature brushless DC motor 2 is on the order of millimeters, which drives the friction assembly 4 to rotate on the measurement surface to generate frictional motion.

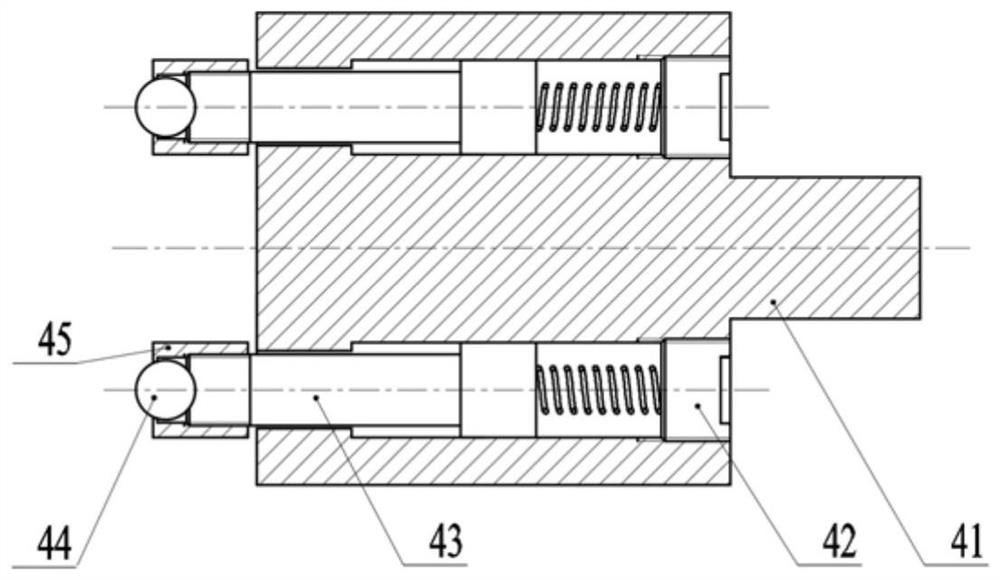

[0049] The friction assembly 4 includes a jacket 41, a spring assembly 42, a guide rod 43, a friction ball 44, and a through-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com