In-situ inspection machine for CNC machining workpiece based on binocular vision

A technology for processing workpieces and binocular vision, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as secondary clamping errors, and achieve the effect of ensuring high precision and large detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

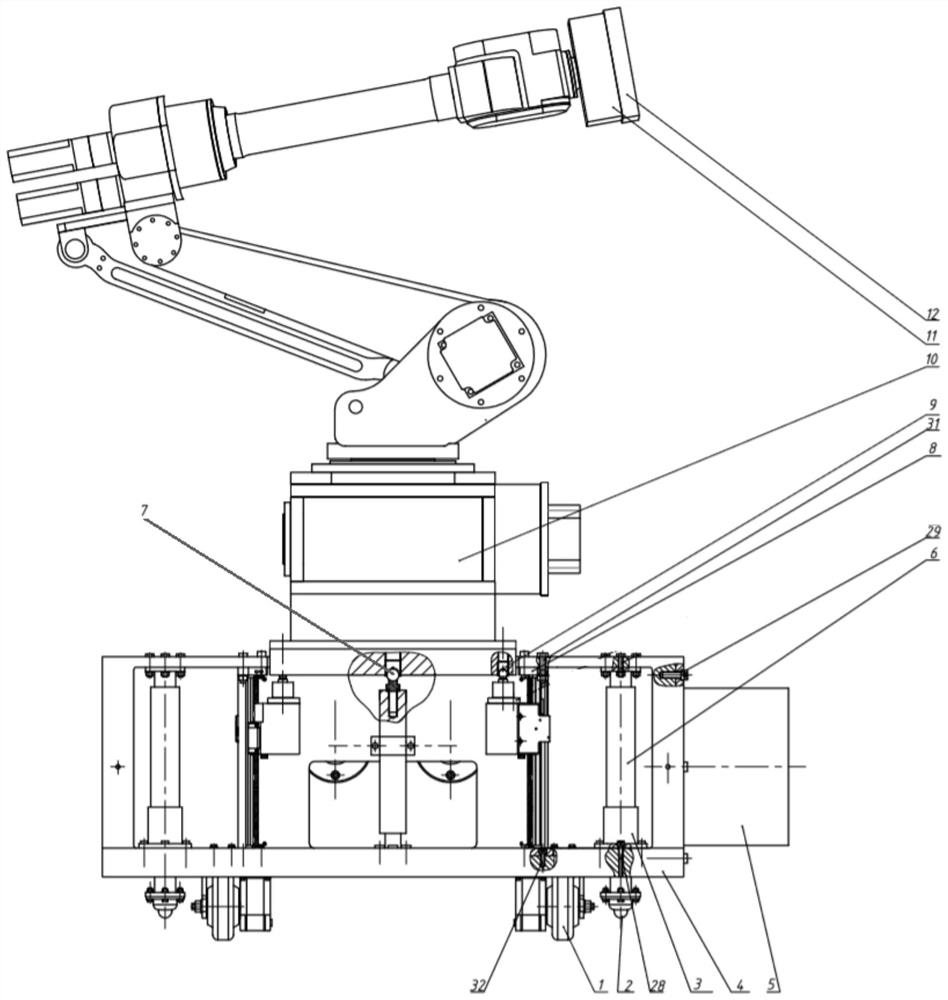

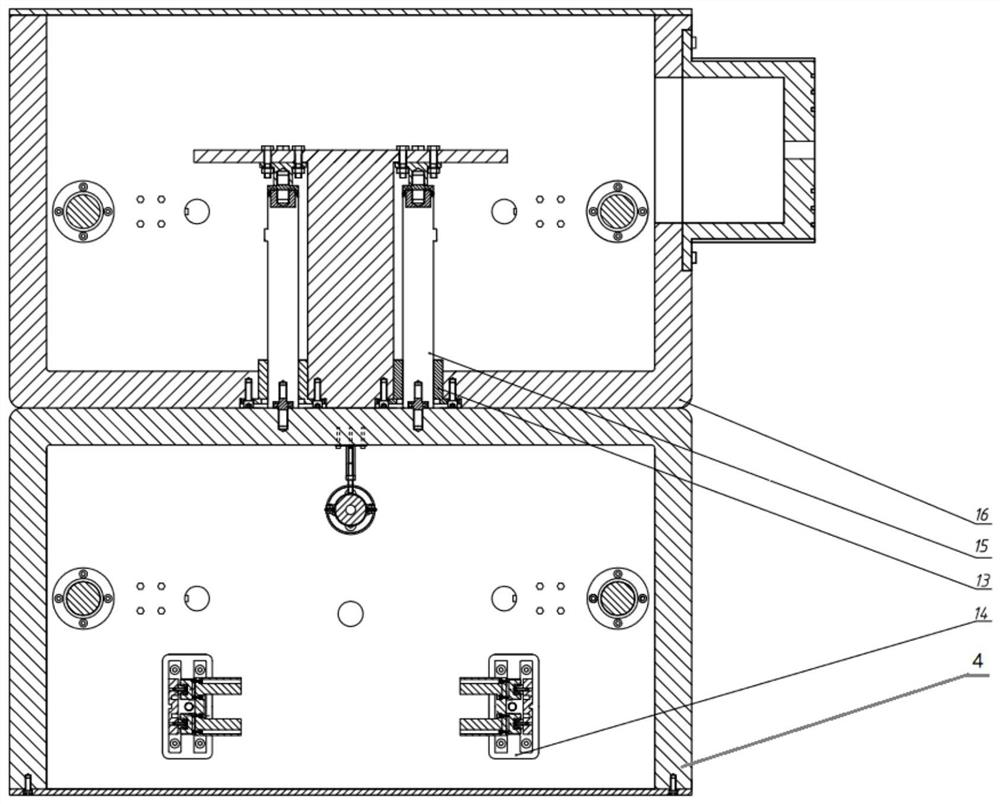

[0022] see Figure 1-5 , the present invention's binocular vision-based numerical control processing workpiece in-position detection machine is composed of a binocular detection component, a self-adjusting level device component, a positioning guide component and a base component.

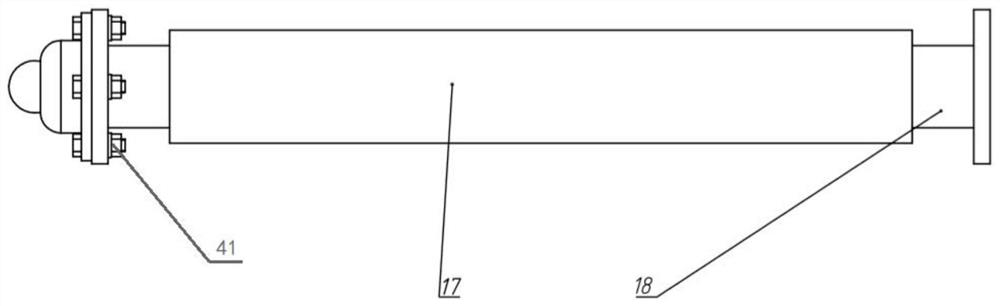

[0023] The binocular detection part includes a binocular camera shield 12, a binocular camera 11, and a mechanical arm part 10. The binocular camera 11 is connected to the execution end of the mechanical arm part 10 by screws, and the mechanical arm part 10 is connected to the self-adjusting horizontal base by screws. 24 connection, the base parts include the front body positioning base 4, the back body positioning base 16, the front and rear telescopic rod assembly 15, the guide positioning plate 13, the front and rear telescopic rod assembly 15 includes a positioning flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com