Binocular stereo vision three-dimensional measurement method based on line structured light scanning

A binocular stereo vision and three-dimensional measurement technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of cumbersome calibration process and low calibration accuracy, reduce the difficulty of matching, ensure measurement accuracy, and improve robustness and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

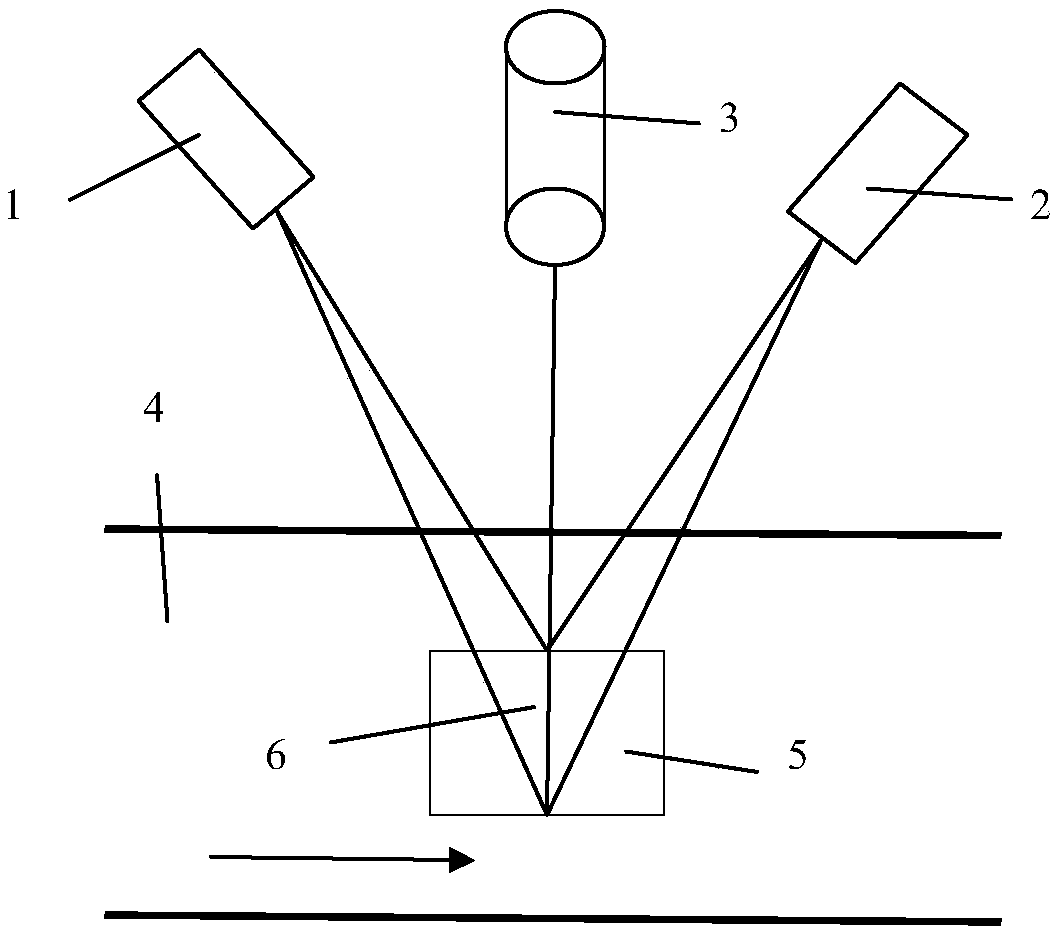

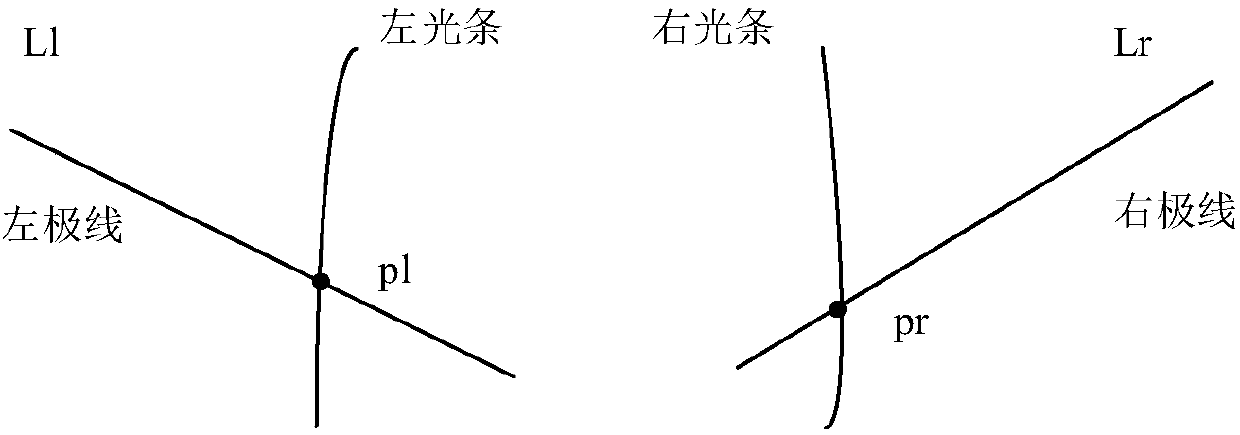

[0050] The technical solution adopted in the present invention is: use the line laser to scan the surface of the workpiece to be measured, the line laser is modulated by the three-dimensional topography of the workpiece surface and deformed, and the line laser light strip is extracted and thinned by the binocular industrial camera imaging system, and based on the Line constraints and light strip position constraints are used to match and reconstruct light strips, so as to obtain the three-dimensional shape of the workpiece to be measured.

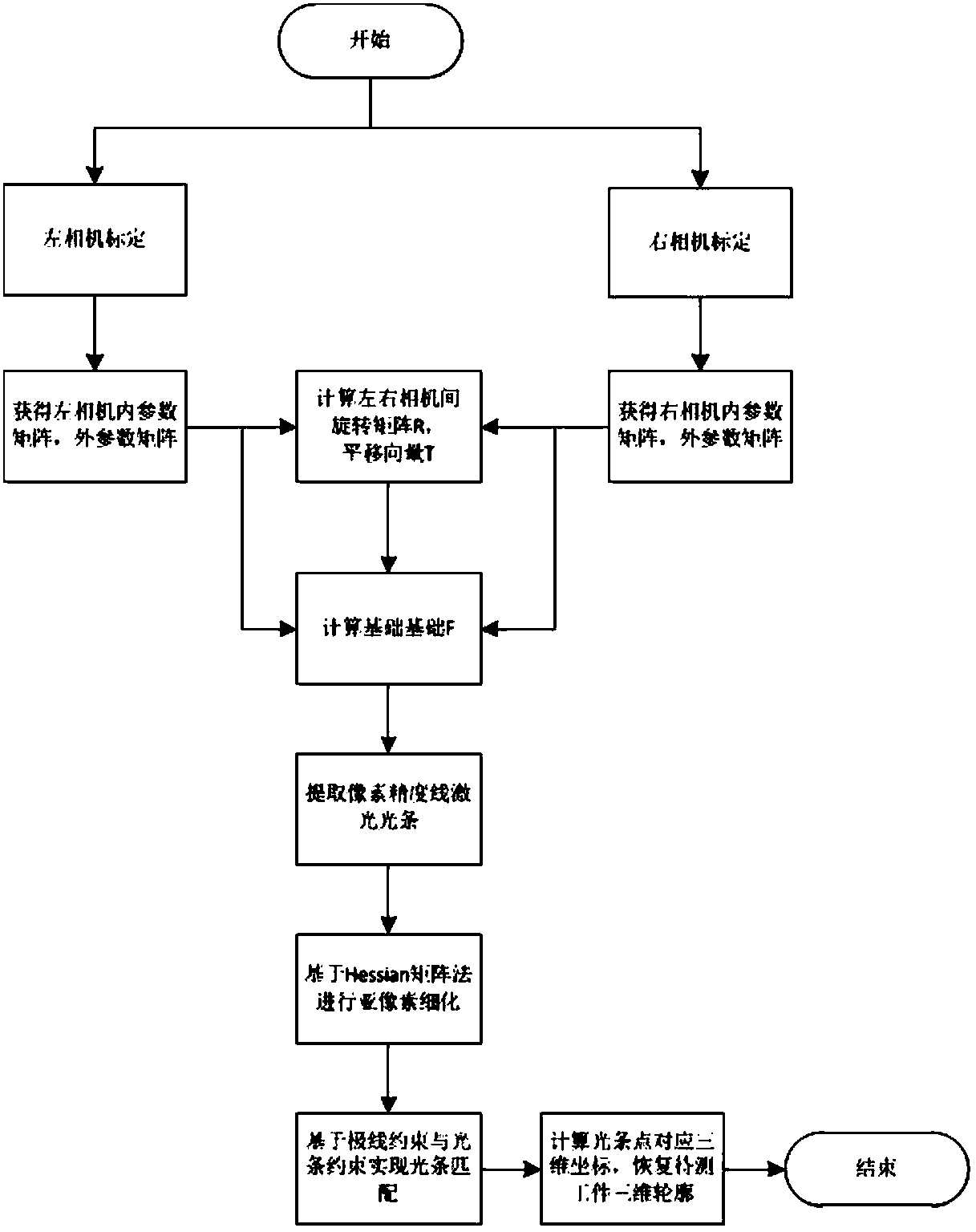

[0051] The three-dimensional measuring method described in the present invention comprises the following steps:

[0052] 1) Use the left camera and the right camera to capture the checkerboard calibration target images at different positions at the same time, extract the sub-pixel-level corner coordinates in the image, and perform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com