Laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects

A laser scanning imaging and non-destructive testing technology, applied in the field of metallurgy, can solve the problems of inability to realize surface and near-surface defect morphology detection, difficult to identify scaly iron oxide scale, inability to detect defect depth information, etc., to improve the continuous casting process technology. , the effect of avoiding loss expansion and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The detection method of the present invention comprises the following steps:

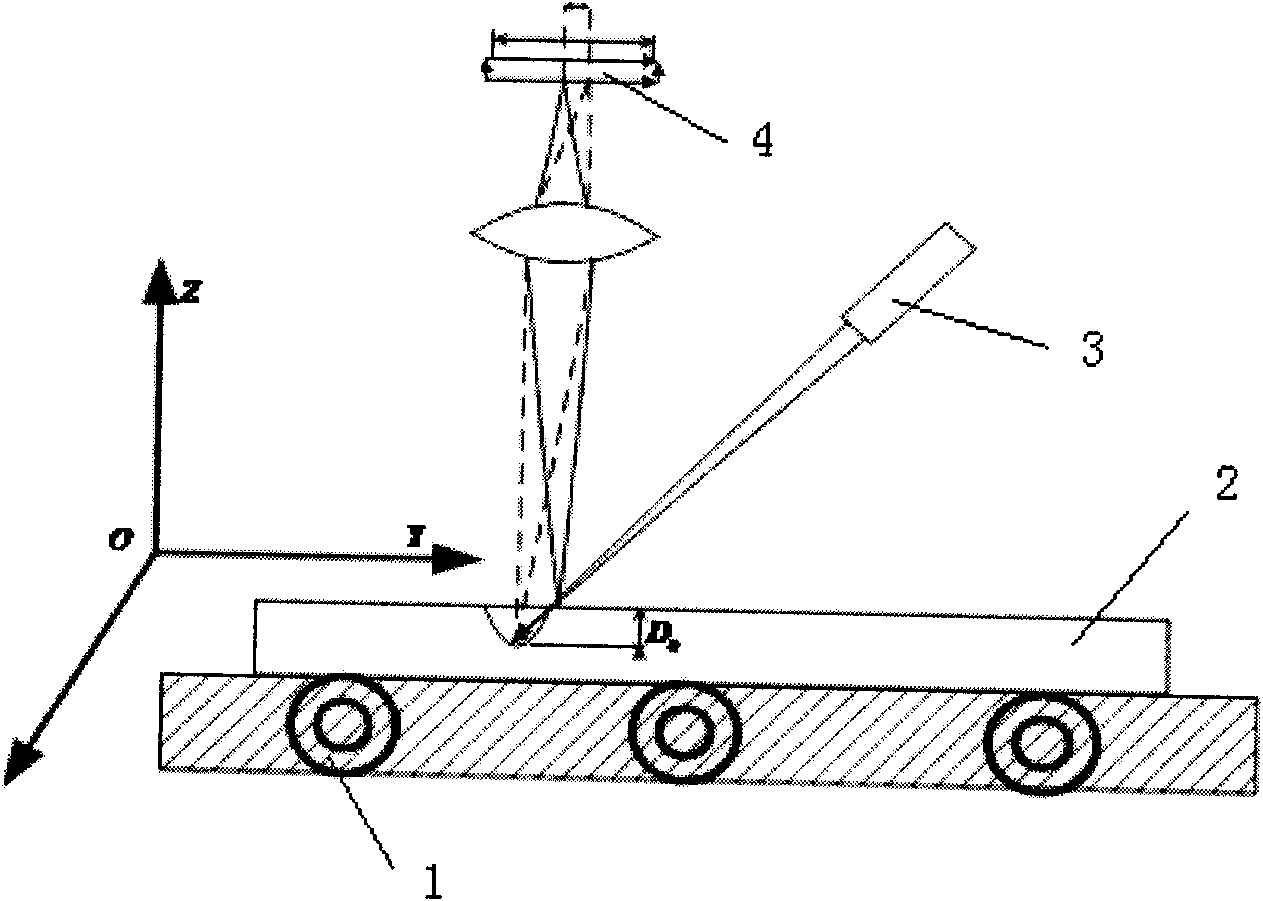

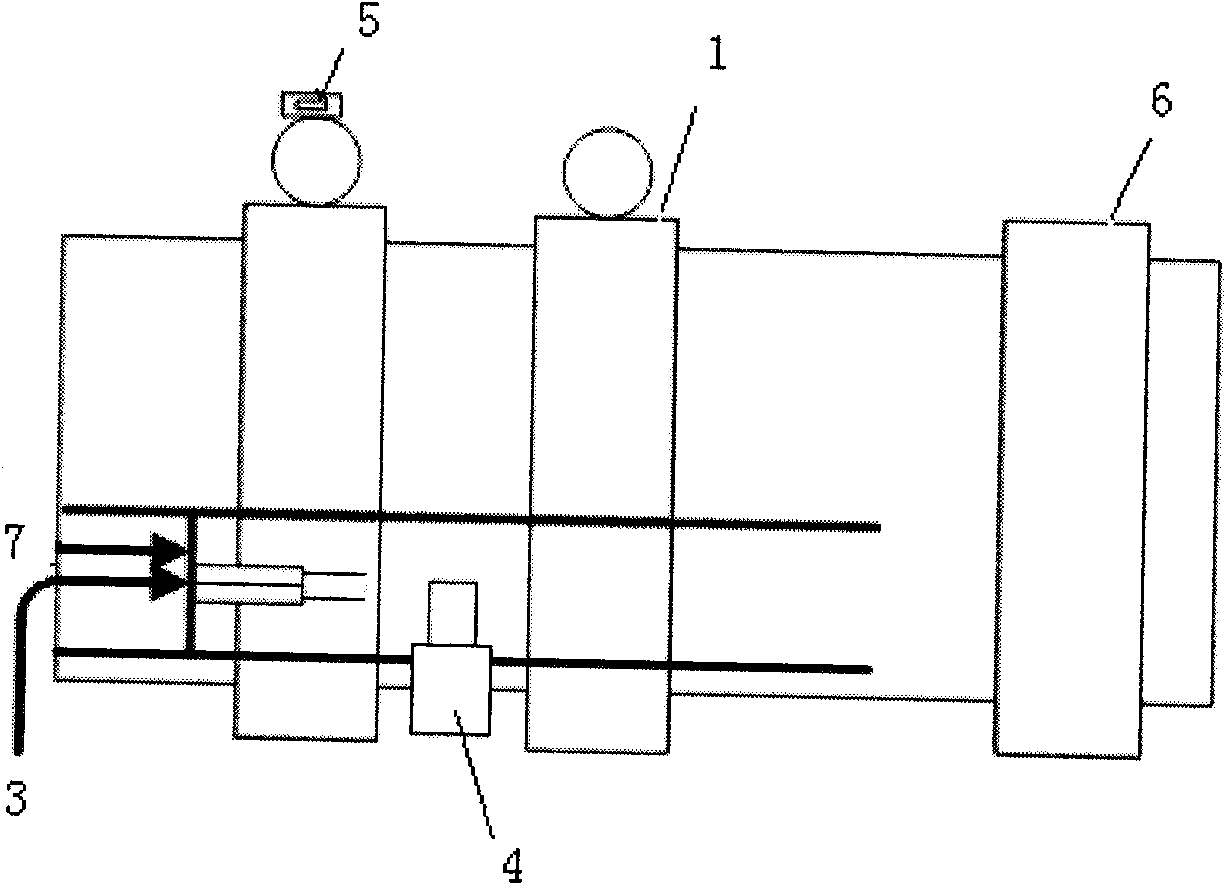

[0022] 1) Install a linear laser emitter above the high-temperature continuous casting slab. The linear laser emitter is installed in a high-temperature protective cover. The linear laser emitter irradiates the slab with laser light in the transverse direction according to a certain emission angle, thereby generating a horizontal line of the slab. (narrow) laser beams;

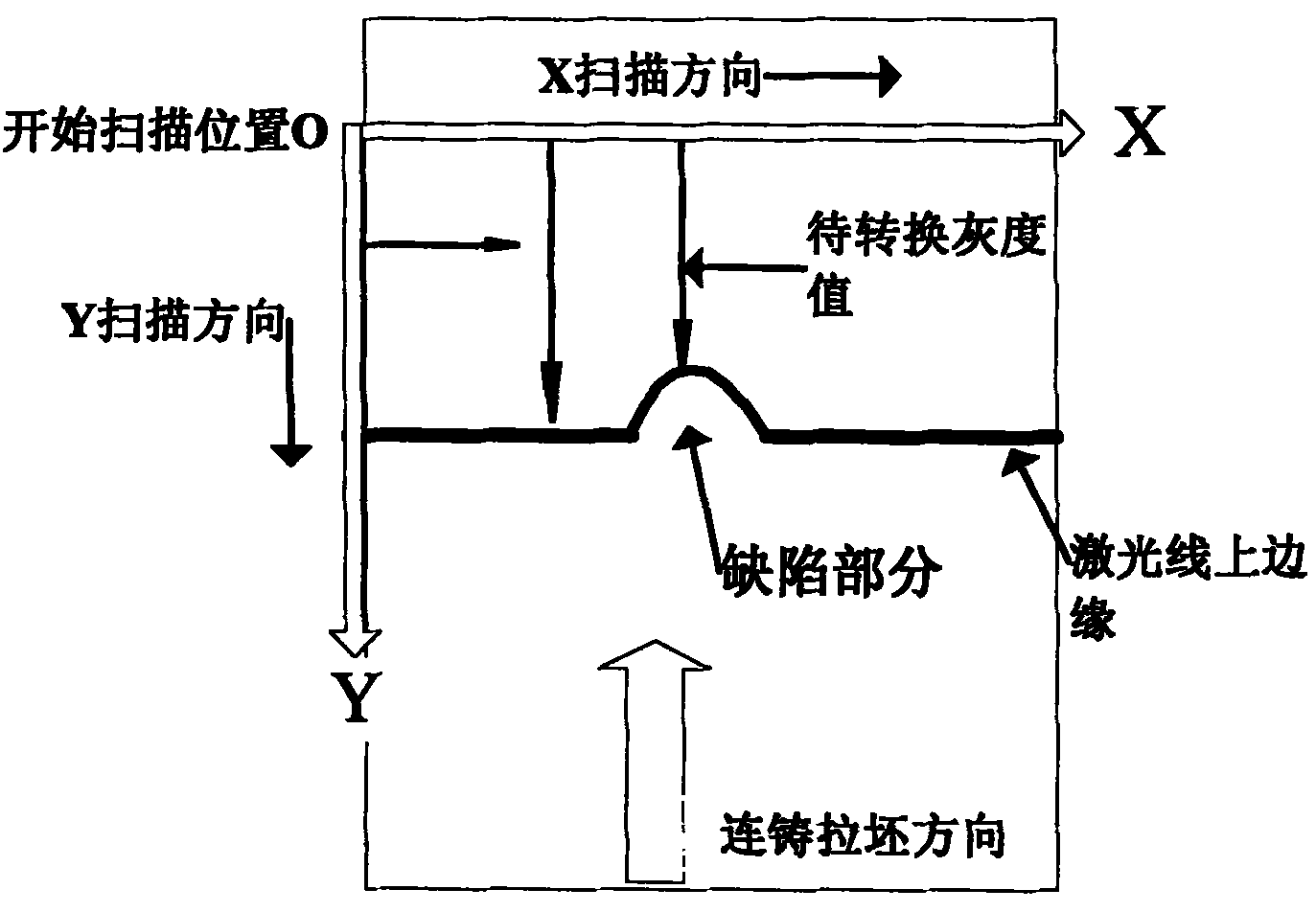

[0023] 2) The laser line beam is scanned by an area array CCD image sensor, and the scanning direction of the area array CCD image sensor is perpendicular to the surface of the high-temperature continuous casting slab and the laser line beam;

[0024] 3) Using the triangular ranging principle to extract the defect depth information represented on the scanned laser beam, the depth information corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com