Laser line scanning feeler geometric transformation calibration and curved face interpolation correcting method and apparatus

A technology of geometric transformation and scanning probe, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex relationship mapping, large difference in accuracy, and difficulty in guaranteeing interpolation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

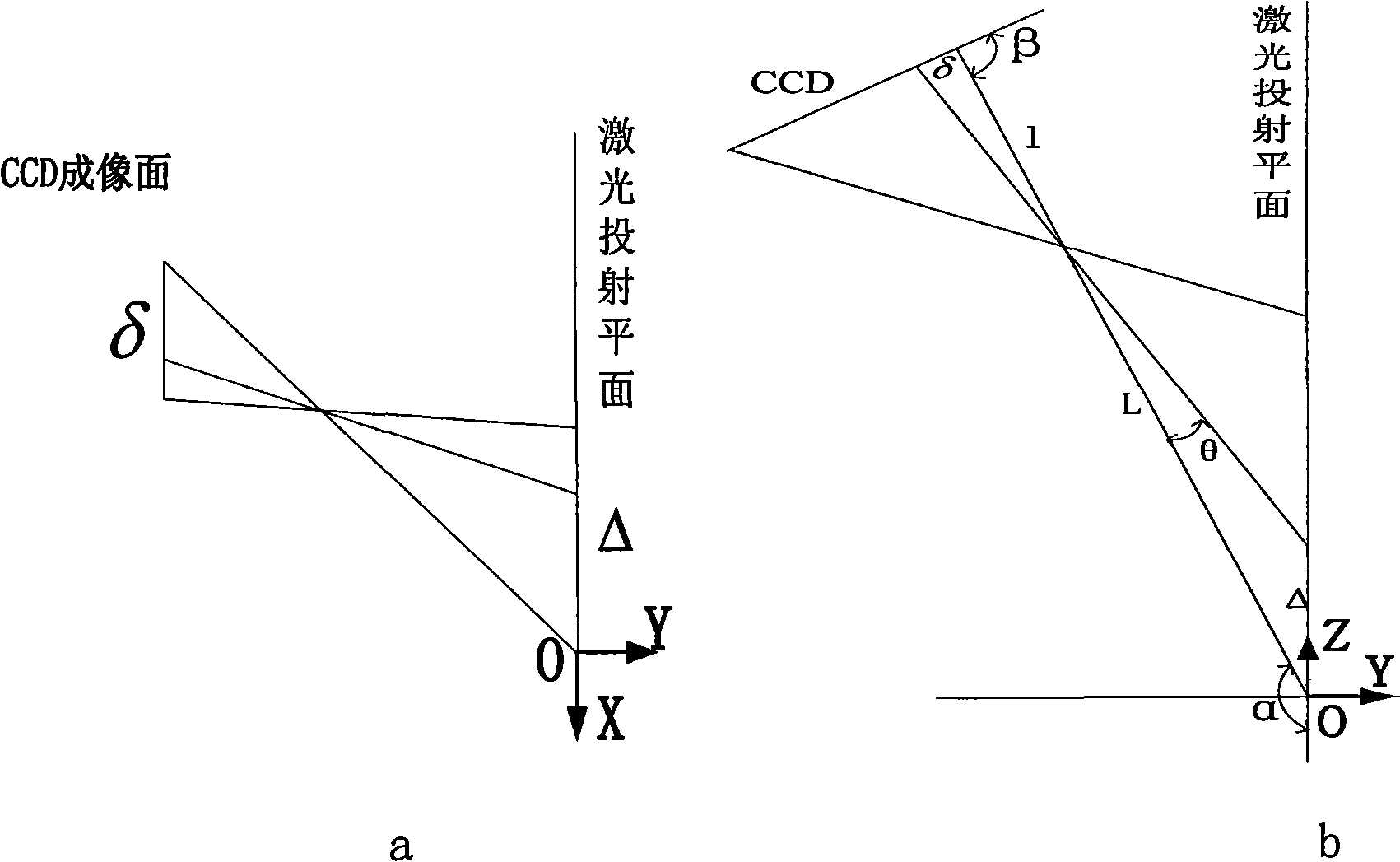

[0041] see figure 1 , and the two figures respectively show the principle of laser line scanning geometric triangulation imaging in the XOY plane and YOZ plane when the laser is vertically incident. Such as figure 1 As shown in a, ideally, in the XOY plane, the image triangle and the object triangle form a similar triangle, and the corresponding side lengths are proportional, so the spatial displacement in the XOY plane of the measured point is proportional to the image displacement of the corresponding imaging point relation.

[0042] And in the YOZ plane, such as figure 1 As shown in b, there is a nonlinear relationship between spatial displacement and image displacement. According to the triangular sine principle, the relevant parameter relationship can be obtained as follows:

[0043] Δ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com