Large-specification high-carbon silicon manganese steel and manufacturing method thereof

A carbon-silicon-manganese steel and large-scale technology, which is applied to large-scale high-carbon silicon-manganese steel and its manufacturing field, can solve the problem of poor center quality of large-scale high-carbon silicon-manganese steel, inability to effectively weld continuous casting billets, and small rolling. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the present invention provides a large-scale high-carbon silicon-manganese steel, the composition mass percentage of the high-carbon silicon-manganese steel is 0.60-1.20wt%, Si: 0.38-0.80wt%, Mn: 1.00-1.90wt%, P: ≤0.020wt%, S: ≤0.005wt%, Al: 0.02~0.06wt%, Nb: 0.020~0.050wt%, Ti: 0.01~0.04wt%, V: 0.025~0.065wt%, Cr: 0.08~ 0.31wt%, Mo: 0.10%-0.50wt%, the rest is Fe and unavoidable impurities.

[0035] Further, the mass percentage of a part of the high-carbon silicon-manganese steel is C: 0.80-1.20wt%, Si: 0.50-0.80wt%, Mn: 1.00-1.50%wt%, Cr: 0.15-0.30wt%, Mo : 0.10% to 0.35wt%.

[0036] Further, the mass percentage of a part of the high-carbon silicon-manganese steel is C: 0.65-1.00wt%, Si: 0.40-0.65wt%, Mn: 1.15-1.45%wt%, Cr: 0.10-0.28wt%, Mo : 0.18% to 0.40wt%.

[0037] Further, the mass percentage of a part of the high-carbon silicon-manganese steel is C: 0.84-1.15wt%, Si: 0.52-0.78wt%, Mn: 1.20-1.90%wt%, Cr: 0.08-0.20wt%, Mo : 0.12% to 0.42wt%.

...

Embodiment 2

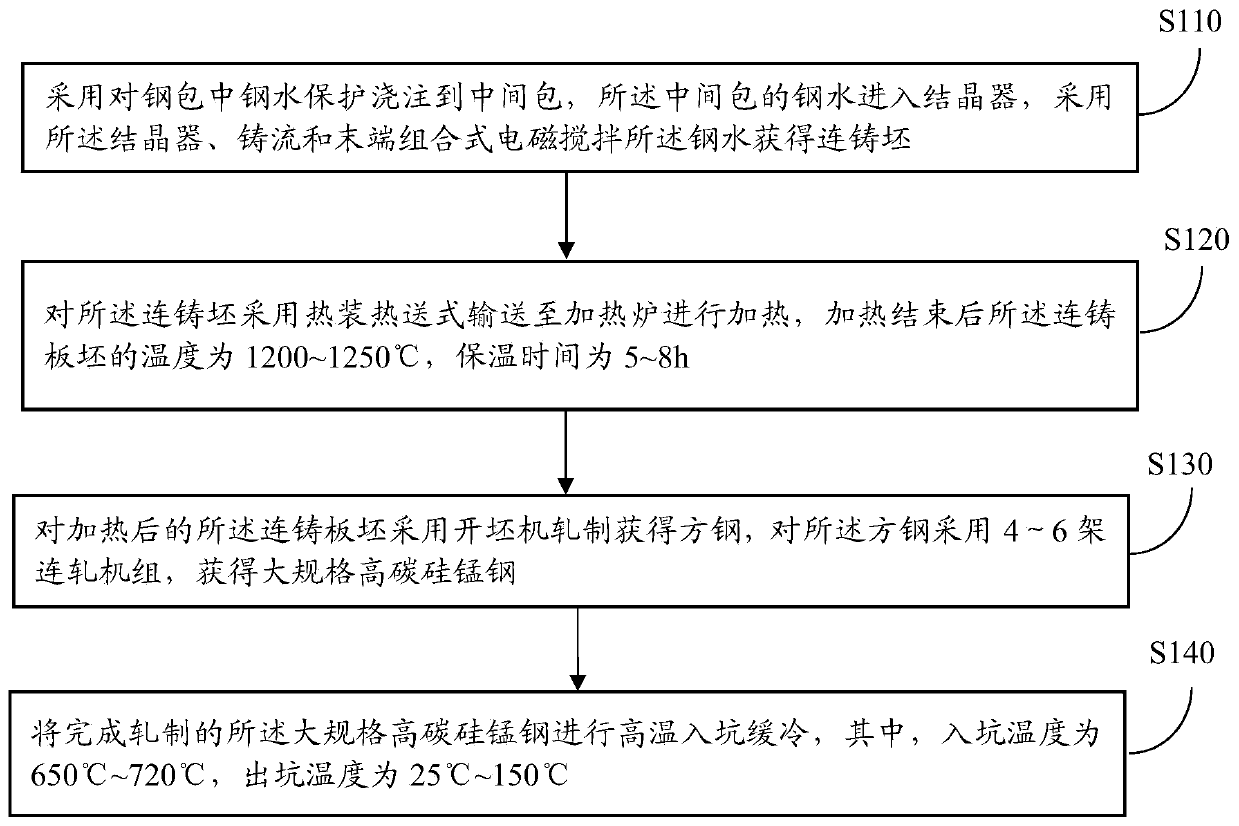

[0040] This embodiment provides a manufacturing method of large-scale high-carbon silicon-manganese steel, please refer to figure 1 , the method includes:

[0041] Step 110: The molten steel in the ladle is poured into the tundish for protection, the molten steel in the tundish enters the mold, and the molten steel is electromagnetically stirred by the combination of the mold, the strand and the end to obtain a continuous casting slab, and the continuous casting slab is obtained. The composition mass percentage of the cast slab is C: 0.60~1.20wt%, Si: 0.38~0.80wt%, Mn: 1.00~1.90wt%, P: ≤0.020wt%, S: ≤0.005wt%, Al: 0.02 ~0.06wt%, Nb: 0.02~0.05wt%, Ti: 0.01~0.04wt%, V: 0.025~0.065wt%, Cr: 0.08~0.31wt%, Mo: 0.10%~0.50wt%, the rest is Fe and unavoidable impurities;

[0042] Further, the tundish adopts double-layer protective agent. Further, the range of electromagnetic stirring current of the crystallizer is 100-400A, and the frequency is 1-5 Hz. Further, the range of electrom...

Embodiment 3

[0054] This embodiment provides a method for manufacturing large-scale high-carbon silicon-manganese steel, which is applied to a large steel factory. The method includes:

[0055] When using electric furnace smelting and continuous casting to produce Ф800mm tool steel 8MnSi, in order to avoid secondary oxidation of molten steel, protective pouring is used from the ladle to the tundish, and the tundish uses double-layer insulation; the combination of mold, casting strand and end is adopted Electromagnetic stirring, the electromagnetic stirring current of the mold is 90A, the frequency is 2Hz, the electromagnetic stirring current of the cast stream is 100A, the frequency is 4Hz, the electromagnetic stirring current of the terminal is 900A, the frequency is 5Hz; the low superheat in the mold The pouring temperature is 25°C; the casting speed in the crystallizer is controlled at 0.3m / min; the specific water volume of the secondary cooling water is 0.7L / kg.

[0056] The continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com