Method for adopting laser cladding to repair TC4-DT titanium alloys

A TC4-DT and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of affecting the performance of the base metal, the economic loss of titanium alloy parts, and the complex structure, so as to prolong the service life and reduce the number of workpieces Effect of high deformation and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Repairing cracks in TC4-DT titanium alloy forgings by laser cladding.

[0044] (1) Prepare 150-300-mesh TC4-DT powder for restoration;

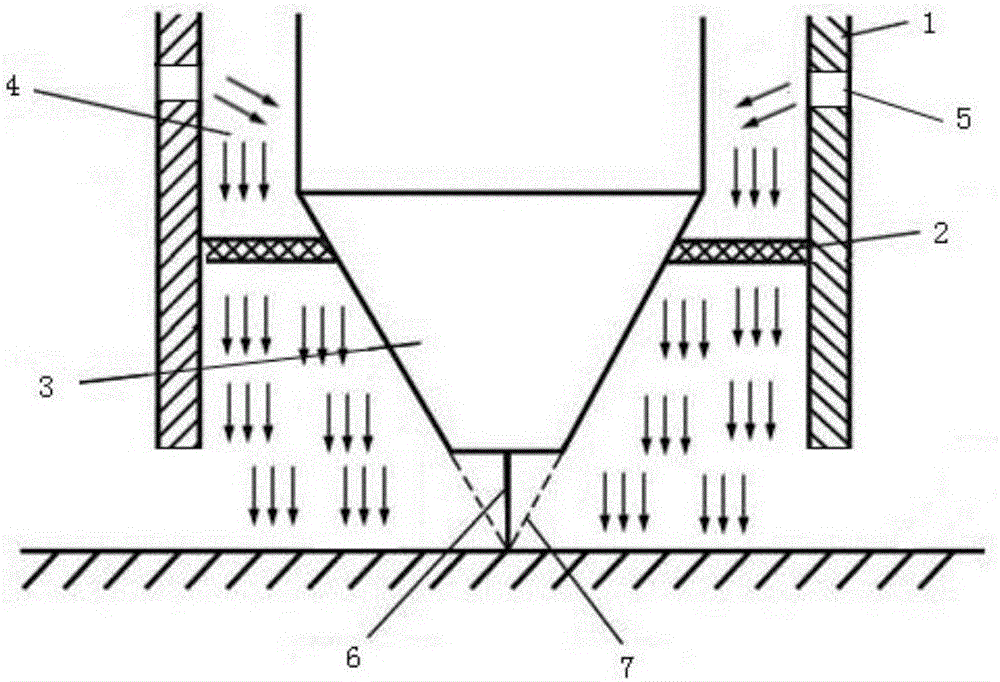

[0045](2) The measured crack length is 17.32 mm. Use a manual grinding gun to completely remove the cracks on the forging, and grind to obtain a V-shaped groove with a length of about 25 mm, a width of about 10 mm, and a depth of about 3 mm, which is cleaned with acetone;

[0046] (3) Install the laser cladding head with additional drag cover and mesh copper sheet;

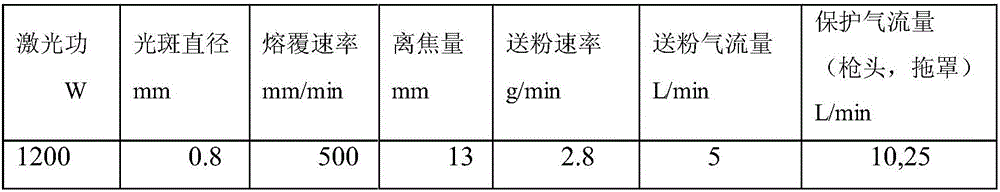

[0047] (4) Carry out laser cladding filling to the polished groove by adopting the process parameters in Table 1;

[0048] The process parameter of table 1 concrete example one

[0049]

[0050] (5) After the repair, the cladding layer is measured to have a machining allowance of 0.64mm;

[0051] (6) Fluorescence detection and X-ray detection are carried out on the repaired workpiece, and there are no cracks, unfused, inclusions and other defects;

[0052] (7) Use t...

Embodiment 2

[0057] Repair of pre-cracks in TC4-DT titanium alloy test block by laser cladding.

[0058] (1) Prepare 150-300-mesh TC4-DT powder for restoration;

[0059] (2) Preset a 10mm crack on the TC4-DT test block, use a manual grinding gun to completely remove the crack on the test block, and grind to obtain a V-shaped groove with a length of about 14mm, a width of about 8mm, and a depth of about 2.5mm. Wipe clean with acetone;

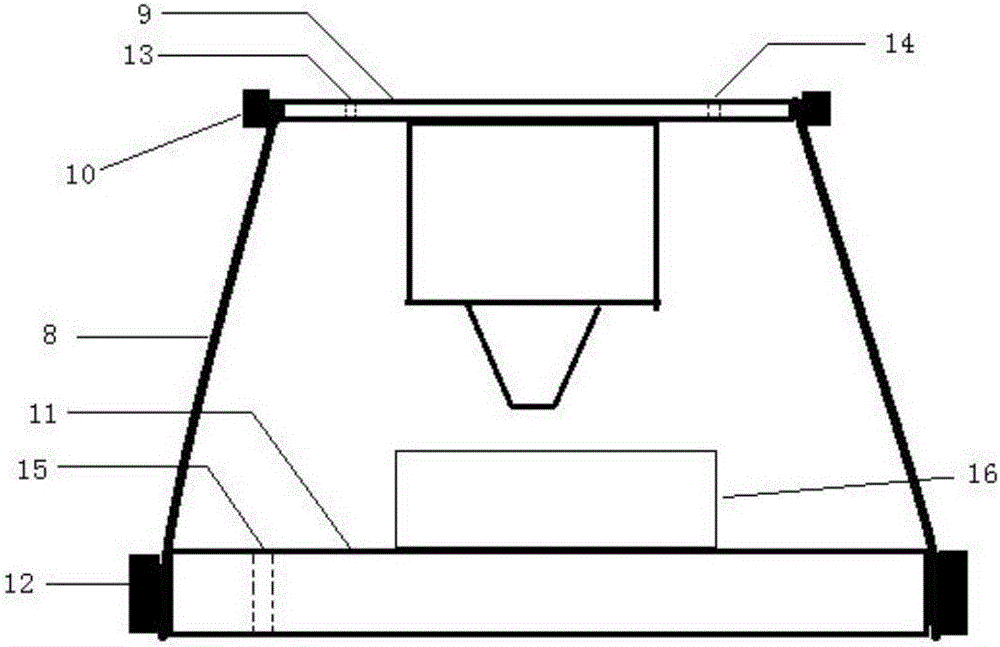

[0060] (3) Install the argon-filled environmental protection cover 8, the upper part of the argon-filled environmental protection cover is installed on the chuck 9 at the rear end of the laser welding head and tightened with a clamp 10, and the lower part of the argon-filled environmental protection cover is installed on the working chassis 11 and clamped The hoop 12 is tightened, the chuck 9 is provided with an exhaust port 13 and an oxygen content measurement port 14, and an air inlet 15 is provided on the chassis of the workbench. The TC4-DT titanium all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com