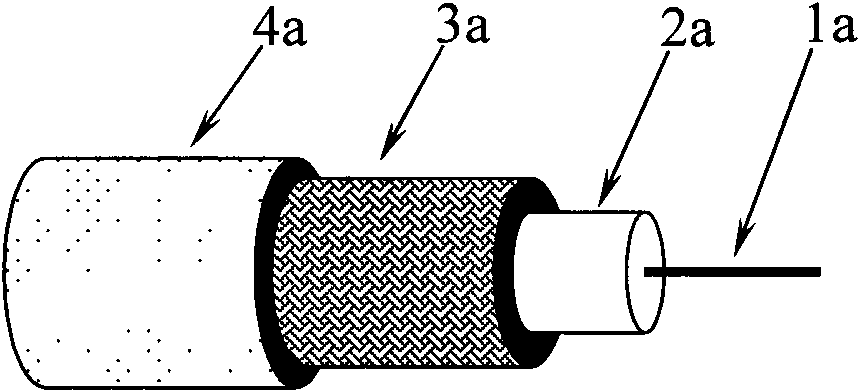

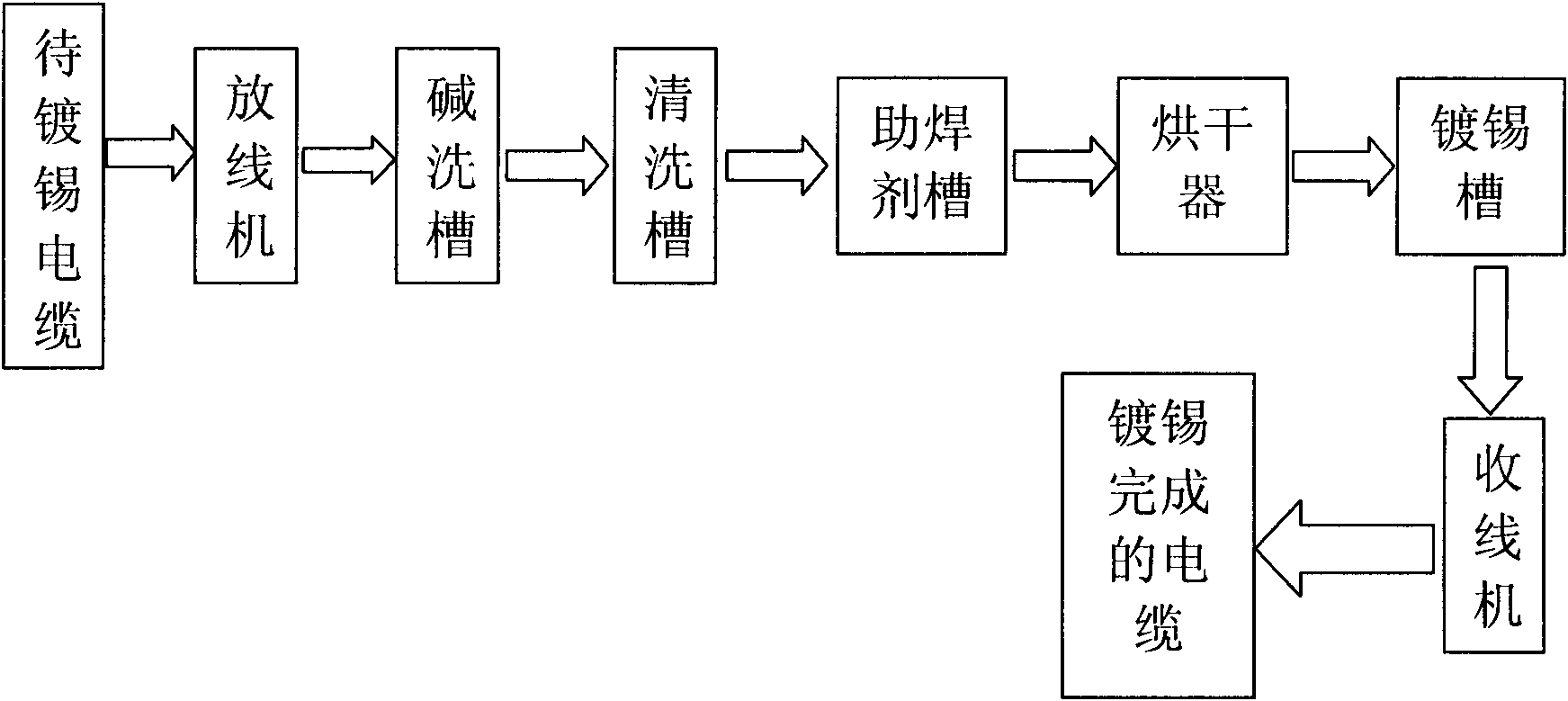

Vertical tinning equipment for semi-flexible coaxial cable shielding layer and tinning method thereof

A semi-flexible coaxial, tin-plating equipment technology, applied in coating, hot-dip plating process, metal material coating process, etc., can solve the problems of low production efficiency, air hole defects, insufficient adhesion of shielding net, etc., and achieve improvement Production efficiency, solution to lack of adhesion, effects of shortening residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

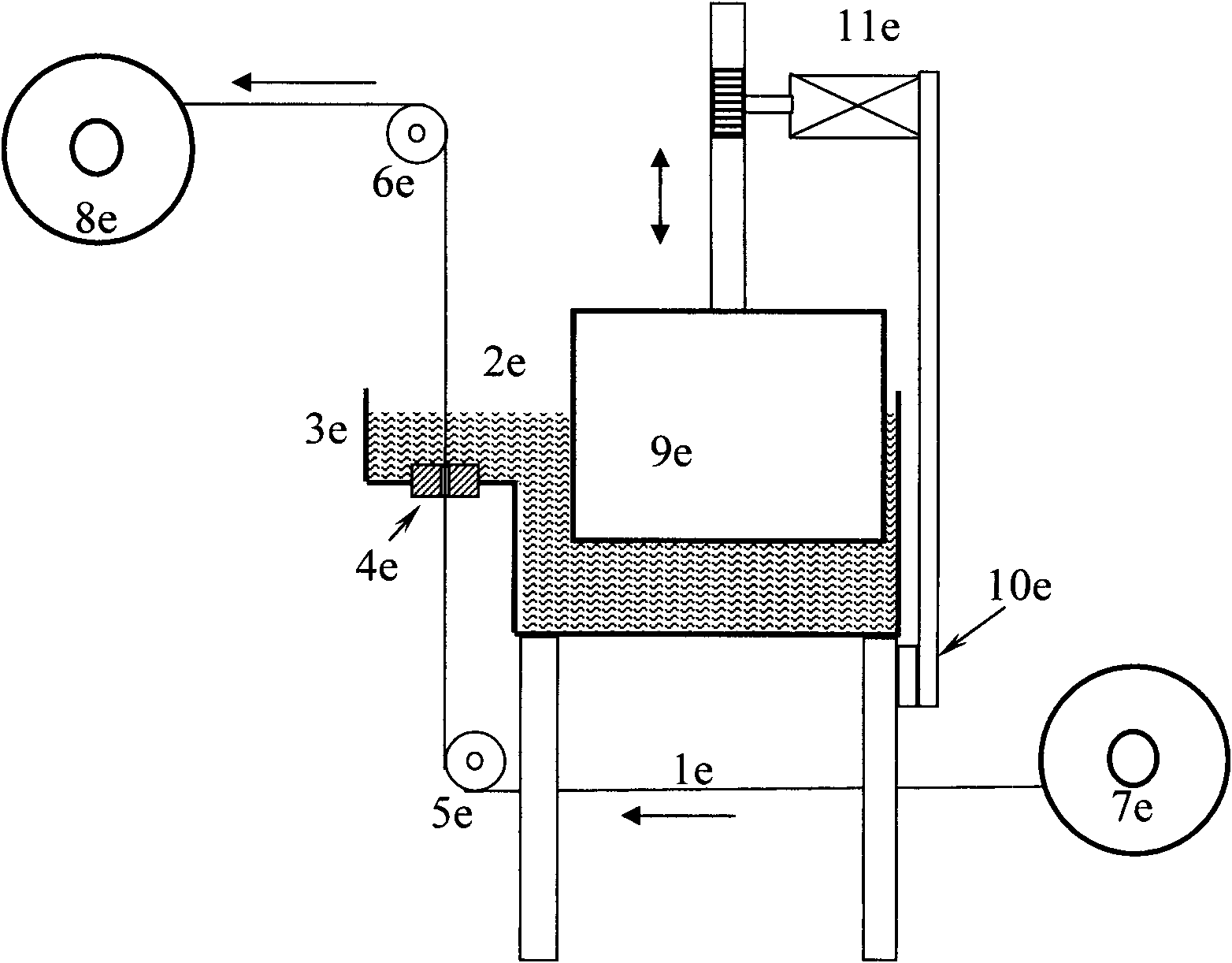

[0029] The device for rapid vertical tinning of the shielding layer of a semi-flexible coaxial cable and the tinning method thereof according to the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0030] The present invention is used for semi-flexible coaxial cable shield layer rapid vertical tinning equipment and tinning method thereof are based on the following mechanism:

[0031] First of all, regarding the air hole defects in the tin plating of the coaxial cable shielding layer, after repeated tests, it was found that these tiny air holes are formed at the moment when the cable leaves the tin bath. The reasons for the analysis are as follows:

[0032] The cables are pre-soaked with flux before entering the tin bath, and some of the flux penetrates the inside of the wire shield. The commonly used lead-free fluxes are basically composed of organic matter, and its main components are prone to generate a large amount of gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com