Laser near net shaping method of low-porosity titanium alumina ceramic piece

A technology of near-net laser shaping and alumina, which is applied in the direction of ceramic products, other household utensils, household utensils, etc., can solve the problems of losing the use value of structural parts, achieve the suppression of thermal growth and cooling shrinkage, solve the problem of pores, expand Effect of Feasible Parameter Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

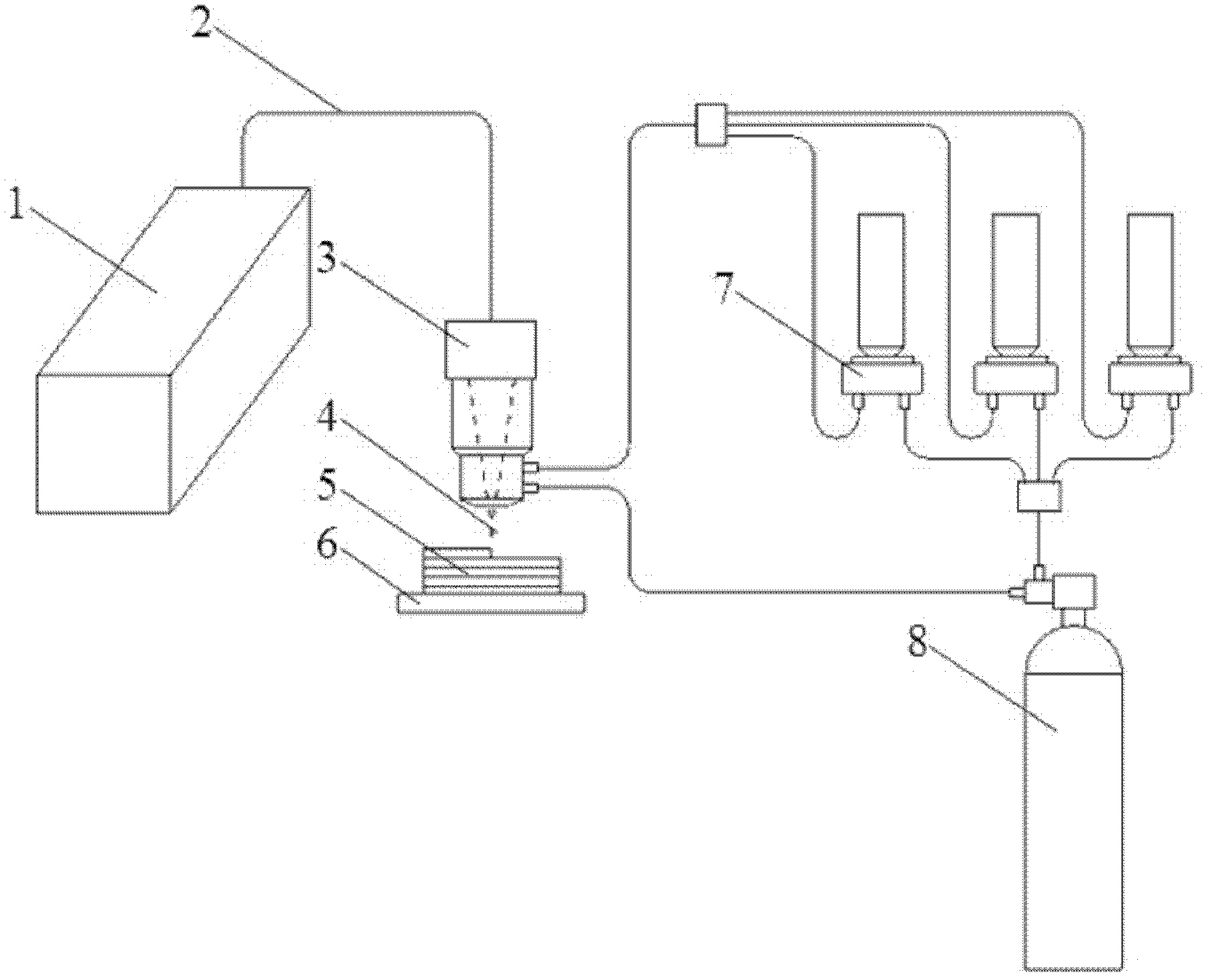

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 As shown, the laser near-net forming method of low porosity alumina-titanium ceramics requires that the embodiment of the present invention: the length of alumina-titanium ceramics is 17mm, the width is 2mm, and the height is 6mm, using JK1002 type Nd:YAG solid The continuous laser performs laser near-net forming on alumina titanium powder, and the specific forming steps are as follows:

[0037] A. Select 42-90 μm near-spherical aluminum oxide titanium according to the requirements, add 10wt.% SiC, mix the powder with a good ratio in a planetary ball mill for 24 hours, and then dry it in an electric blast drying oven at 100°C for 4 hours;

[0038] B. Before processing, sand the forming substrate 6 with sandpaper and clean it with alcohol;

[0039] C. Put the pretreated composite powder into the powder feeder 7, and adjust the working distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com