Jet dispensing device and technology

A technology of injection point and process, which is applied to the device and coating of surface coating liquid, can solve the problems of high manufacturing process requirements, complicated technical operation, and difficult control of glue injection volume, so as to improve quality and consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

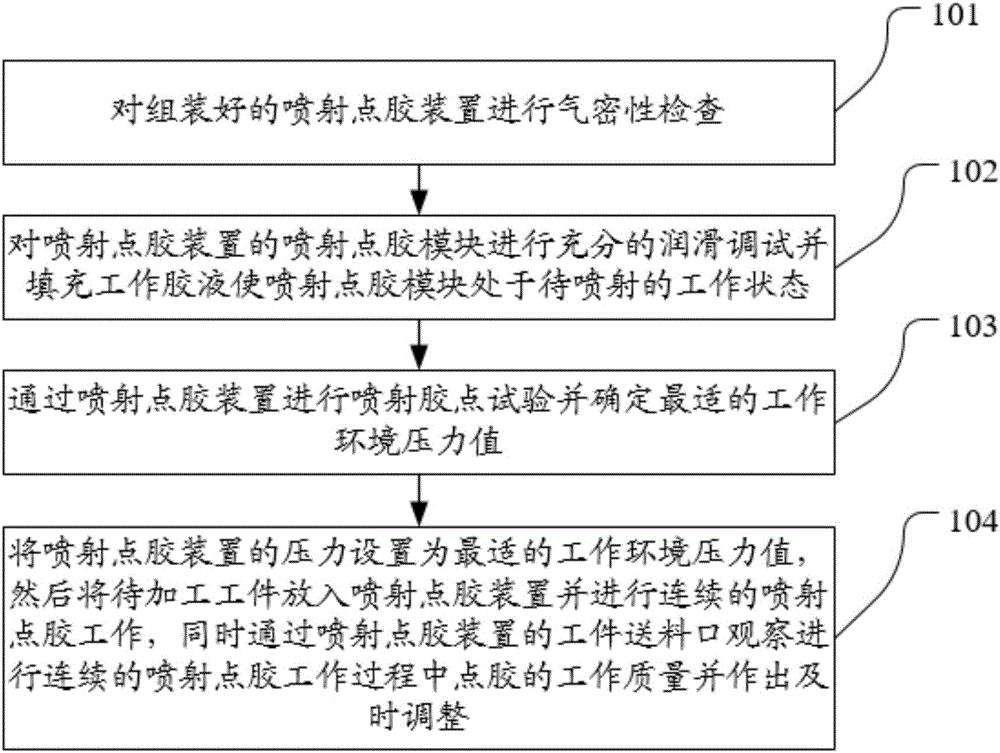

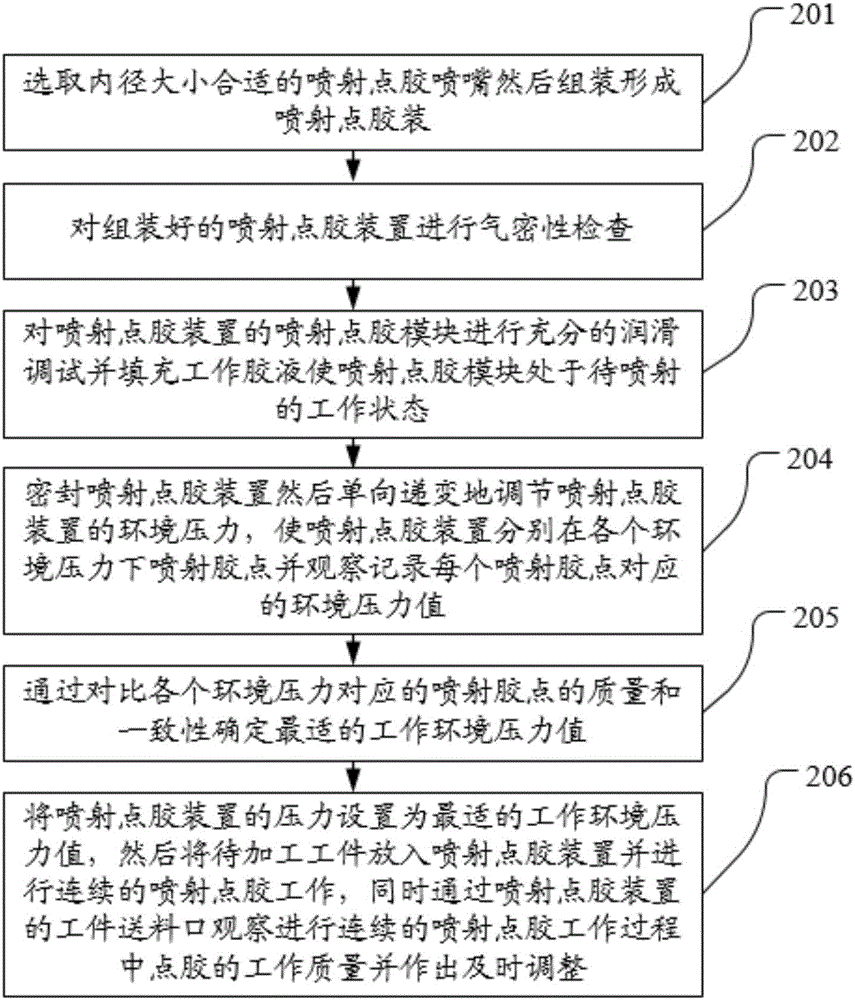

[0042] The embodiment of the present invention discloses a jet dispensing device and process. The environmental pressure of jet dispensing is controlled to the optimum working environment pressure value obtained in advance experiments through a low-pressure generating device and a low-pressure working box, effectively suppressing high-speed, micro-volume The degree of deformation and splashing caused by the collision between the jet glue droplet and the wall surface of the workpiece mounting substrate, and between the droplet and the droplet effectively improves the quality and consistency of the jet dispensing, and solves the problems in the prior art. The precision of the required instruments is high, it is difficult to control the injection volume of the glue, the manufacturing process requires high requirements, and the technical operation is complicated, which leads to the technical problem of greatly reducing the injection efficiency.

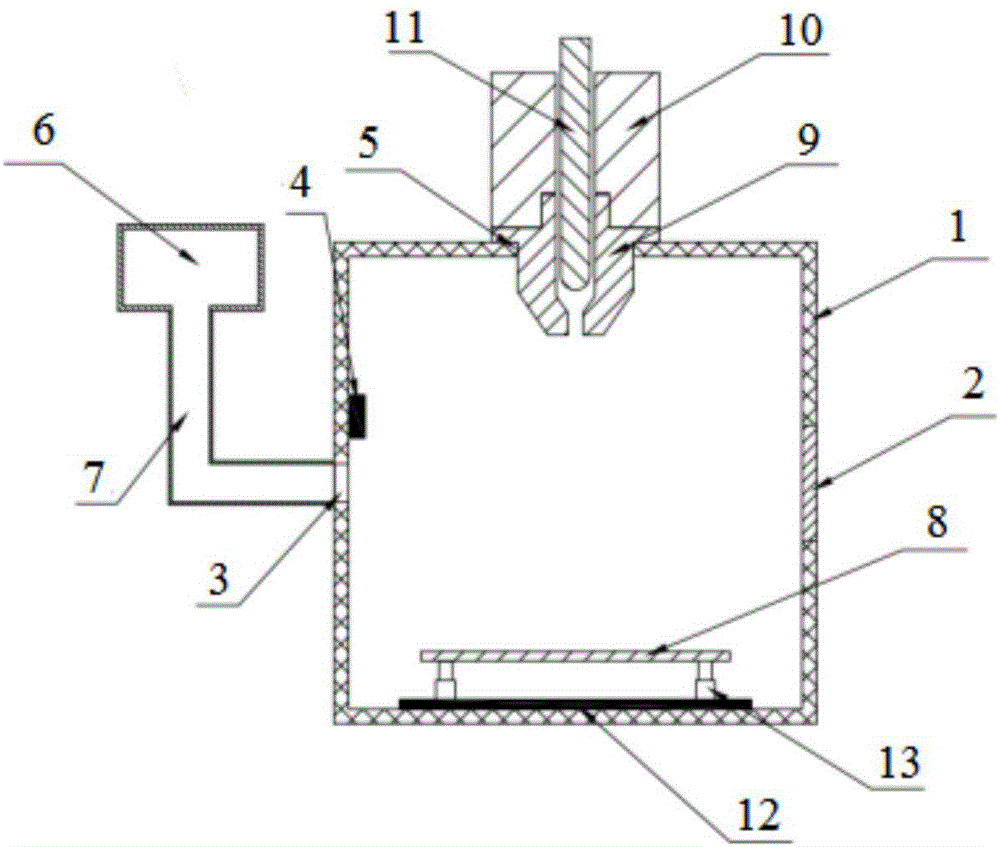

[0043] see figure 1 , an embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com