Material for manufacturing boat and process method for manufacturing boat through material

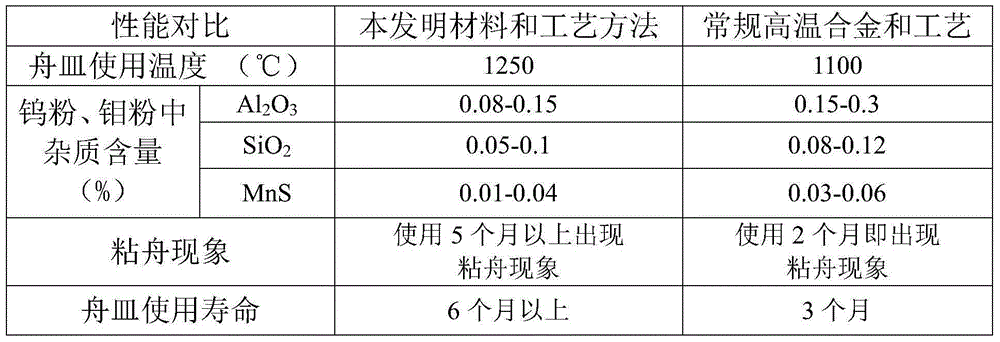

A process method and a boat technology are applied to high-temperature boat materials and the field of preparing boats for high-temperature reduction furnaces, which can solve the problems of unsatisfactory boat materials, production and application limitations, and single materials, so as to reduce material costs, Improved appearance quality and high dimensional accuracy of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) batching; batching is carried out according to the weight ratio of each composition in the material described in the present invention: metal nickel 90Kg, metal tungsten: 57.5Kg, graphite: 150 grams, metal titanium 300 grams, rare earth silicon 400 grams;

[0026] (2) Manufacture presses and press wax molds; use pressure to press the wax into the presses of aluminum alloy materials, wherein the presses are processed by numerical control, and the waxes are cast waxes at medium temperature, and are taken out after cooling and solidification;

[0027] (2) Shell making: coating and hanging refractory material on the surface of the wax mold to form a refractory shell, in which 830 silica sol is used as the adhesive for the surface layer, zircon sand and zirconium powder are used for the ingredients, and 1430 silica sol is used as the adhesive for the reinforcement layer , the ingredients are made of mullite and mullite powder, and the process of forming a hard shell must ...

Embodiment 2

[0034] (1) batching; batching is carried out according to the weight ratio of each composition in the material described in the present invention: metal nickel 175Kg, metal tungsten: 120Kg, graphite: 300 grams, metal titanium 600 grams, rare earth silicon 800 grams;

[0035] (2) Manufacture presses and press wax molds; use pressure to press the wax into the presses of aluminum alloy materials, wherein the presses are processed by numerical control, and the waxes are cast waxes at medium temperature, and are taken out after cooling and solidification;

[0036] (2) Shell making: coating and hanging refractory material on the surface of the wax mold to form a refractory shell, wherein the surface layer uses 830 silica sol as the adhesive, the ingredients use zircon sand and zirconium powder, and the reinforcement layer adopts 1430 silica sol as the adhesive, The ingredients are mullite and mullite powder, and the process of forming a hard shell must be repeated many times to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com