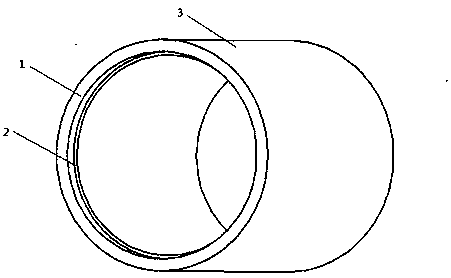

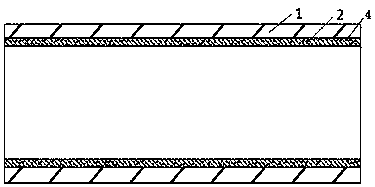

Composite metal pipe with internal glass coating and preparation process of composite metal pipe

A composite metal pipe and inner coating technology, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy cracks and seepage, attenuation of pipeline transportation capacity, non-wear-resistant resin lining, etc., to achieve wear-resistant Excellent resistance and aging resistance, low resistance, and the effect of solving non-wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh glass powder raw materials according to the following volume percentage: ZnO30%, B 2 o 3 25%, P 2 o 5 15%, Bi 2 o 3 10%, Al 2 o 3 10%, Fe 2 o 3 10%; mix the raw materials according to the ordinary glass powder preparation process→melt→ball mill→sieve to prepare glass powder; weigh glass slurry raw materials according to the number of parts by mass: 80 parts of the above-mentioned glass powder, with a median particle size of 1.5 μm 10 parts of copper powder, 10 parts of stainless steel powder with a median particle size of 1.5 μm; the raw materials were added into the adhesive according to the glass slurry preparation process, and then mixed and ball-milled to prepare a coating slurry with good suspension; The centrifuge of the drying device, under the action of centrifugal force, coats the slurry on the inner surface of the stainless steel pipe and dries and solidifies it at 90°C to form a layer of green body with a thickness of 0.2mm on the inner surface ...

Embodiment 2

[0024] Weigh glass powder raw materials according to the following volume percentage: ZnO40%, B 2 o 3 15%, P 2 o 5 10%, Bi 2 o 3 15%, Al 2 o 3 15%, Fe 2 o 3 5%; the raw materials are mixed according to the ordinary glass powder preparation process → melting → ball milling → sieving to prepare glass powder; take glass slurry raw materials by mass parts: 75 parts of the above-mentioned glass powder, copper with a median particle size of 1 μm 25 parts of powder; the raw materials are added into the adhesive according to the glass slurry preparation process, mixed and ball milled, and prepared into a coating slurry with good suspension; then, using a centrifuge with a drying device, under the action of centrifugal force, the The slurry is coated on the inner surface of the white copper tube and dried and solidified at 100°C to form a layer of 0.5mm thick green body on the inner surface of the white copper tube; then the white copper tube with the green layer is dried in a ...

Embodiment 3

[0026] Weigh glass powder raw materials according to the following volume percentage: ZnO50%, B 2 o 3 10%, P 2 o 5 10%, Bi 2 o 3 10%, Al 2 o 3 10%, Fe 2 o 3 9%, 1%TiO 2 The raw materials are mixed according to the ordinary glass powder preparation process → melting → ball milling → sieving to prepare glass powder; take glass slurry raw materials by mass parts: 80 parts of the above-mentioned glass powder, stainless steel powder with a median particle size of 0.8 μm 20 parts; the raw materials are added into the adhesive according to the glass slurry preparation process, mixed and ball-milled, and prepared into a coating slurry with good suspension; then, the slurry is mixed under the action of centrifugal force by using a centrifuge with a drying device. The material is coated on the inner surface of the stainless steel pipe and dried and solidified at 110°C to form a layer of 0.8mm thick green body on the inner surface of the stainless steel pipe; then the stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com