Covering agent for chromium zirconium copper smelting as well as preparation method and use method thereof

A covering agent, chrome-zirconium-copper technology, applied in the field of covering agent for high-strength and high-conductivity alloy smelting, chrome-zirconium-copper smelting, can solve the problems of low welding cost, uneven composition, scrapping, etc., and achieve the solution of porosity, Effective, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Select 65% silicate, 15% carbonate, 5% fluoride, 6% chloride, 5% boron, and 4% oxide, and configure the melt covering agent according to the above ratio. Packaged in bags.

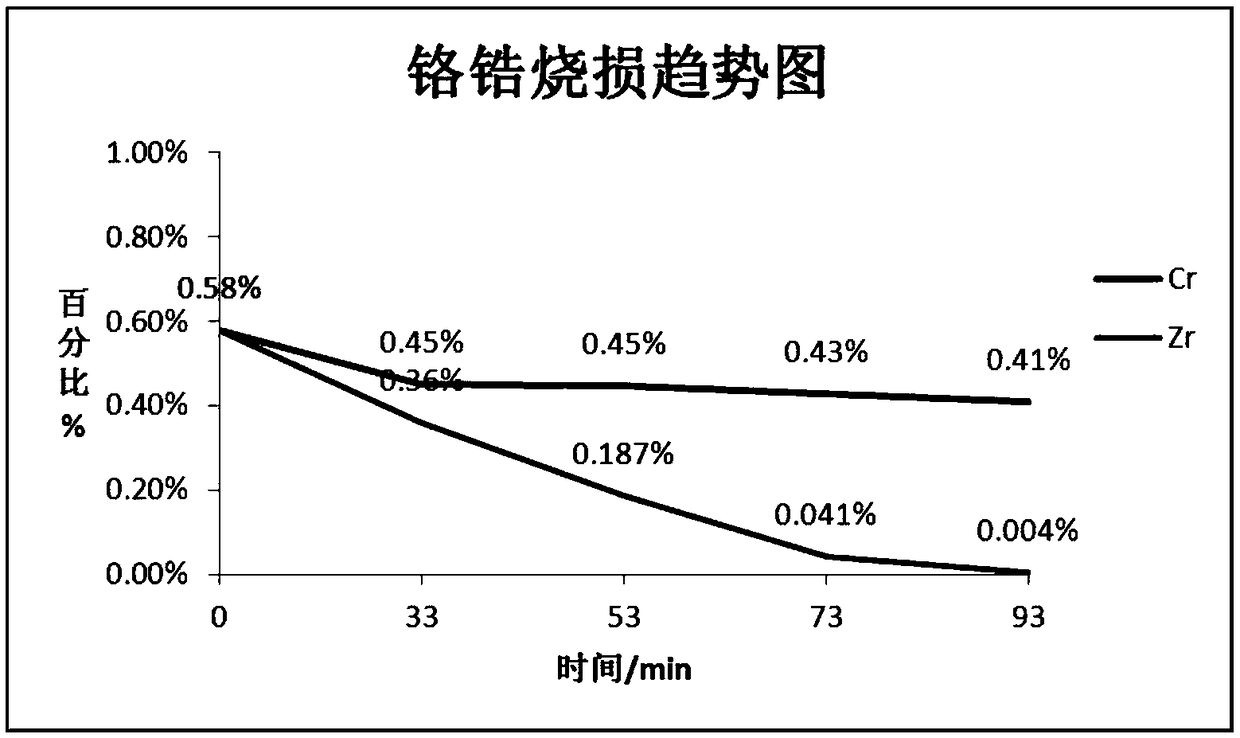

[0033] In a non-vacuum state, chrome-zirconium copper is smelted in a 50kg medium-frequency induction furnace. After the copper is melted, a covering agent is added, and the temperature is raised to about 1300°C. The thickness of the surface is about 2mm. At the same time, add metal chromium and keep it warm for more than 10 minutes, then lower the voltage, control the temperature at 1180 ° C ~ 1240 ° C, add copper-zirconium master alloy, keep warm, record the change of zirconium burning loss, and the trend of chromium zirconium burning loss Such as figure 1 shown.

Embodiment 2

[0035] Select 70% of silicate, 10% of carbonate, 5% of fluoride, 6% of chloride, 5% of boron and 4% of oxide, and configure the melt covering agent according to the above ratio. Packaged in bags.

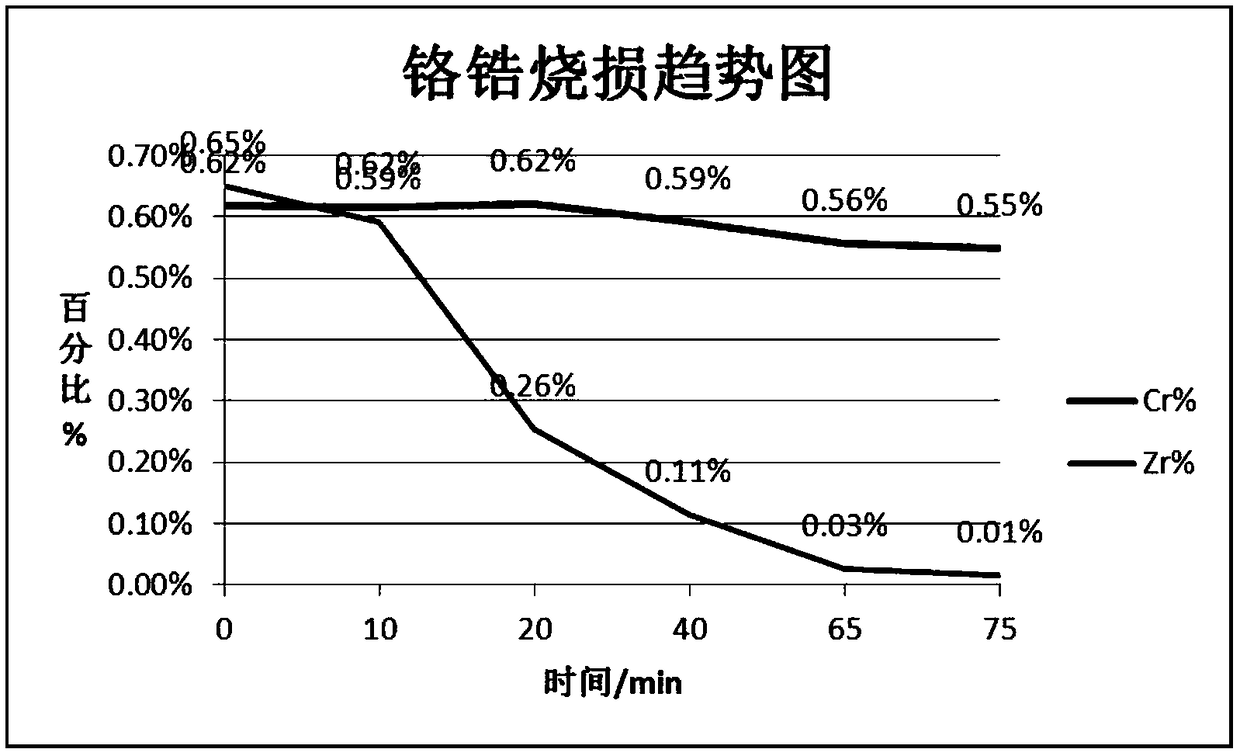

[0036] In a non-vacuum state, chrome-zirconium copper is smelted in a 50kg medium-frequency induction furnace. After the copper is melted, a covering agent is added, and the temperature is raised to about 1300°C. The thickness of the surface is about 2mm. At the same time, add metal chromium and keep it warm for more than 10 minutes, then lower the voltage, control the temperature at 1180 ° C ~ 1240 ° C, add copper-zirconium master alloy, keep warm, record the change of zirconium burning loss, and the trend of chromium zirconium burning loss Such as figure 2 shown.

Embodiment 3

[0038] Select 75% of silicate, 5% of carbonate, 5% of fluoride, 6% of chloride, 5% of boron and 4% of oxide, and configure the melt covering agent according to the above ratio. Packaged in bags.

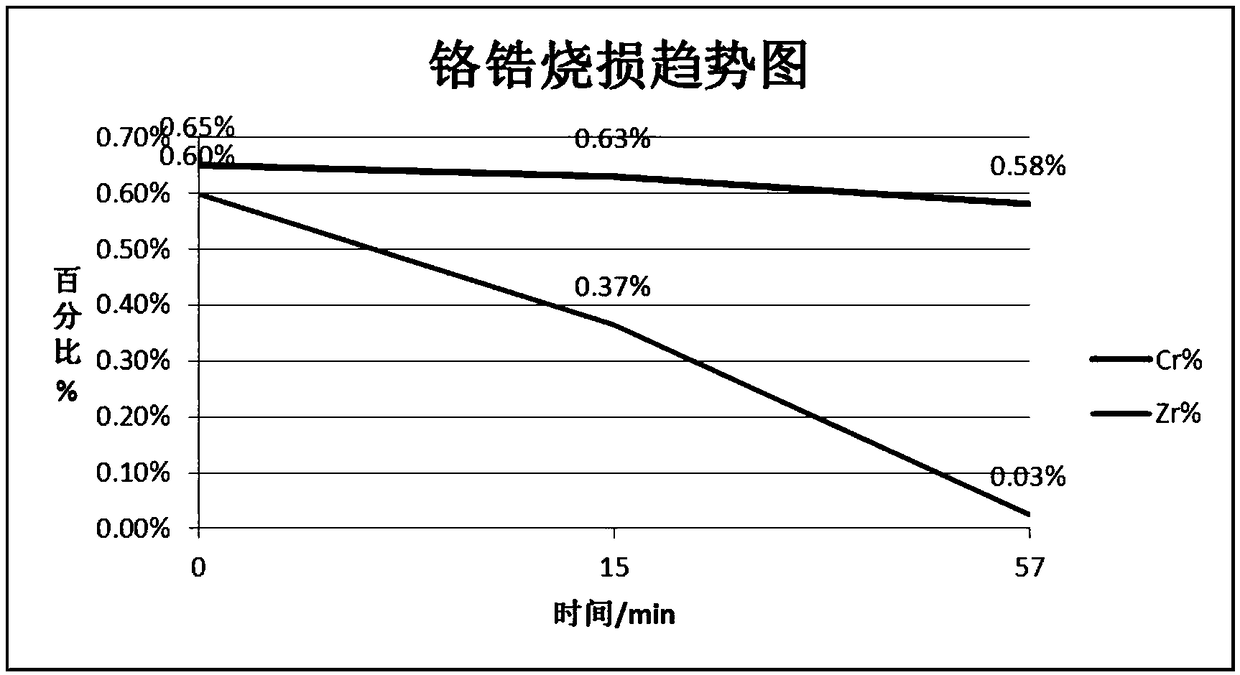

[0039] In a non-vacuum state, chrome-zirconium copper is smelted in a 50kg medium-frequency induction furnace. After the copper is melted, a covering agent is added, and the temperature is raised to about 1300°C. The thickness of the surface is about 2mm. At the same time, add metal chromium and keep it warm for more than 10 minutes, then lower the voltage, control the temperature at 1180 ° C ~ 1240 ° C, add copper-zirconium master alloy, keep warm, record the change of zirconium burning loss, and the trend of chromium zirconium burning loss Such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com