High temperature-resistant filter tip of cigarette, preparation method and application thereof

A technology of high temperature resistance and cigarette filter, applied in the application, e-liquid filter, tobacco and other directions, can solve the problems of high temperature resistance and low smoke efficiency of filter tips in new cigarette cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

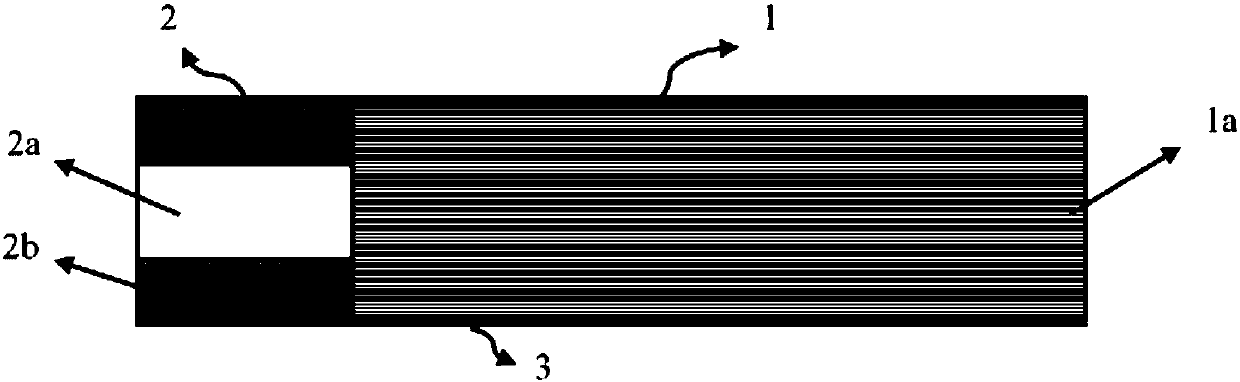

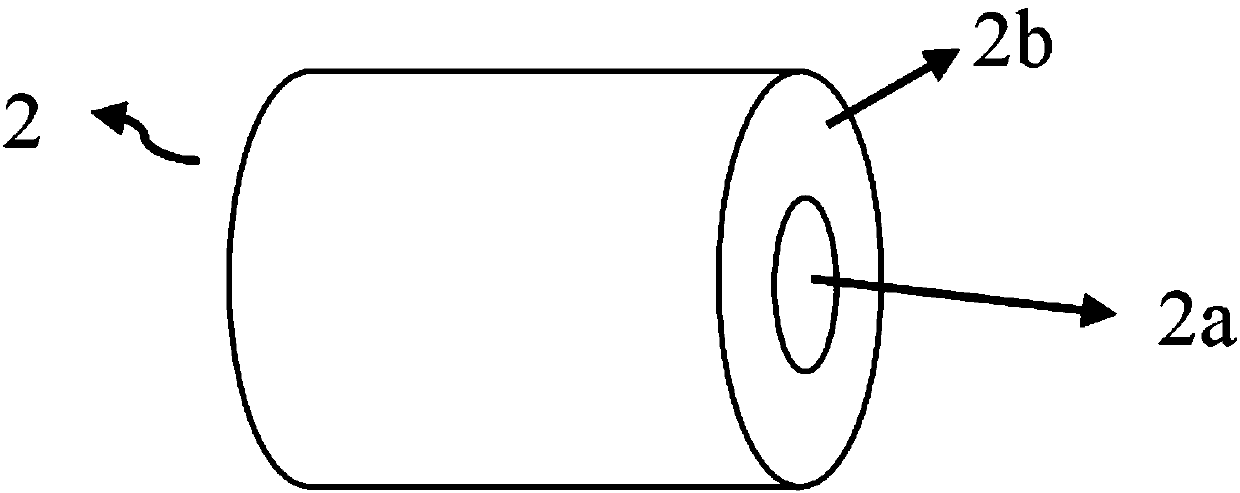

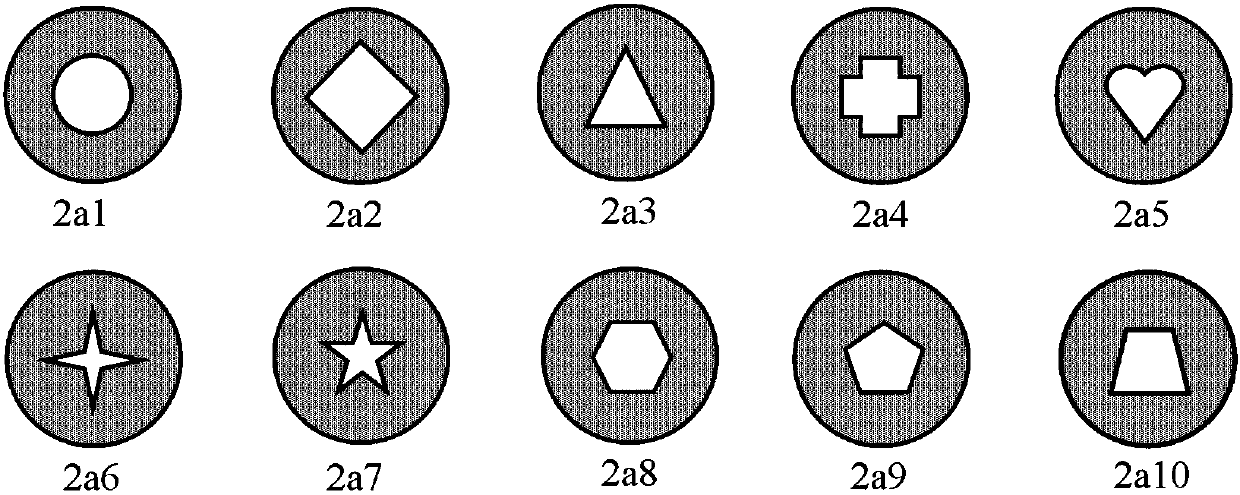

[0041] A high temperature resistant smoke filter, the structure of which refers to figure 1 , figure 2 , consisting of tow section 1, high temperature resistant functional section 2 and forming paper 3. The tow section is made of cellulose acetate tow 1a, and the pressure drop of the tow section is 600Pa. The high temperature resistant functional section 2 is composed of an airflow channel 2a and a main body 2b, and the airflow channel 2a runs through the high temperature resistant functional section 2 . Such as image 3 As shown in Figure a1, there is an airflow channel 2a in the high temperature resistant functional section 2, the cross section of the airflow channel 2a is circular, and the axis of the airflow channel 2a and the main body 2b are on the same straight line. The diameter of the main body 2b is 7.4 mm, and the cross-sectional area ratio of the air flow channel 2a and the main body 2b is 8:10. The length ratio of the high temperature resistant functional sec...

Embodiment 2

[0049] A high temperature resistant smoke filter, the structure of which refers to figure 1 , consisting of tow section 1, high temperature resistant functional section 2 and forming paper 3. The tow section 1 is made of cellulose acetate tow 1a, and the pressure drop of the tow section 1 is 400Pa. The high temperature resistant functional section 2 is composed of an airflow channel 2a and a main body 2b, and the airflow channel 2a runs through the high temperature resistant functional section 2 . Such as image 3 As shown in Figure a2, there is an airflow channel 2a in the high temperature resistant functional section 2, the cross section of the airflow channel 2a is square, and the axis of the airflow channel 2a and the main body 2b are on the same straight line. The diameter of the main body 2b is 7.4mm, and the ratio of the cross-sectional area of the airflow channel 2a to the main body 2b is 1:5. The length ratio of the high temperature resistant functional section 2...

Embodiment 3

[0058] A high temperature resistant smoke filter, the structure of which refers to figure 1 , consisting of tow section 1, high temperature resistant functional section 2 and forming paper 3. The tow section 1 is made of cellulose acetate tow 1a, and the pressure drop of the tow section 1 is 300Pa. The high temperature resistant functional section 2 is composed of an airflow channel 2a and a main body 2b, and the airflow channel 2a runs through the high temperature resistant functional section 2 . Such as image 3 As shown in Figure a3, there is an airflow channel 2a in the high temperature resistant functional section 2, the cross section of the airflow channel 2a is an equilateral triangle, and the axis of the airflow channel 2a and the main body 2b are on the same straight line. The diameter of the main body 2b is 7.4mm, and the ratio of the cross-sectional area of the airflow channel 2a to the main body 2b is 1:10. The length ratio of the high temperature resistant fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com