Drilling device for underground gas holes and drilling method thereof

The technology of a drilling device and a drilling method is applied in the field of drilling devices for underground gas holes, which can solve problems such as easy collapse of underground gas holes, and achieve the effects of stabilizing the rock wall, increasing the extraction volume, and increasing the concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

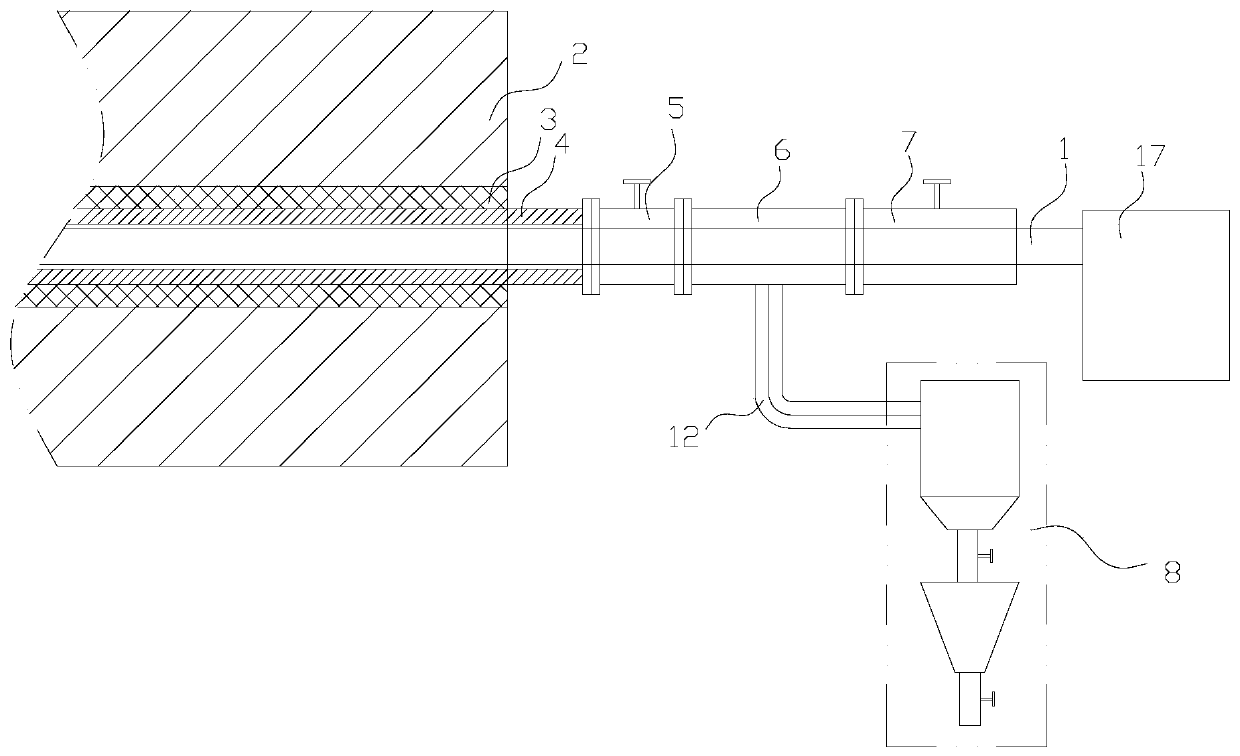

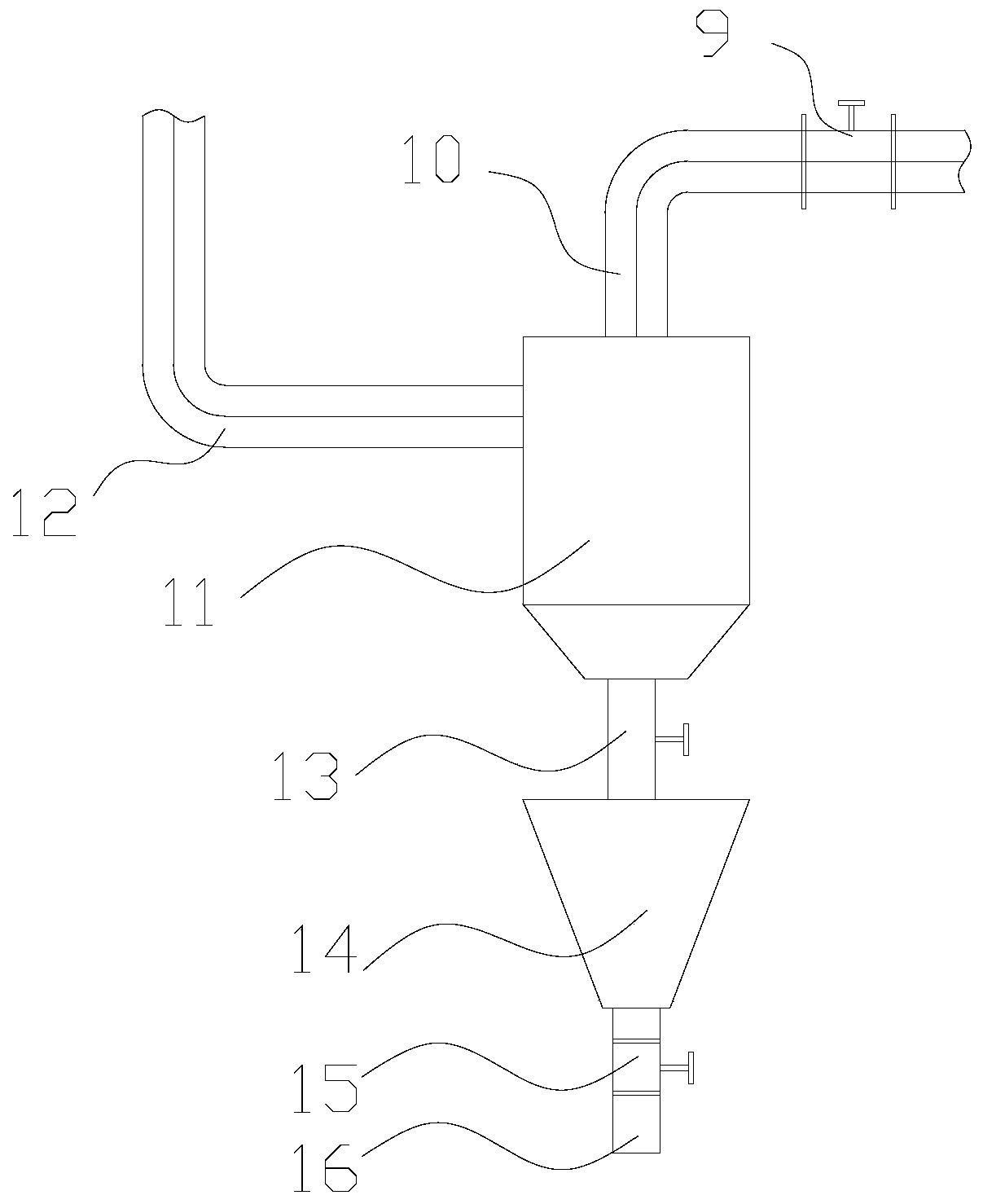

[0033] refer to figure 1 and figure 2 , a drilling device for an underground gas hole, comprising a drill pipe 1, a sealing casing 4, a pressure maintaining valve 5, a three-way pipe 6, a dynamic and static combined sealing device 7, a drilling rig 17 and a water slag separation device.

[0034] Wherein, the drill pipe 1 is connected with the drilling rig 17, and the drill pipe 1 has a hollow structure. When drilling, the inner hole of the drill pipe 1 will be used to pressurize and supply the cooling liquid to the hole in the coal rock layer, which is used to clean the end of the drill pipe 1. At the same time, the coolant can flush the cut cuttings out of the drill hole and support the hole wall.

[0035] The hole-sealing sleeve 4 is sealed and fitted at the mouth of the gas hole, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com