Thin-wall aluminum alloy three-plate butting one-time fusion welding process method

A process method and aluminum alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as difficult to remedy, burn through, and easy collapse of aluminum alloy sheets, and achieve the effect of convenient design and improved working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A thin-walled aluminum alloy three-plate butt welding process method, the specific steps are:

[0020] The first step is to prepare the welding workpiece

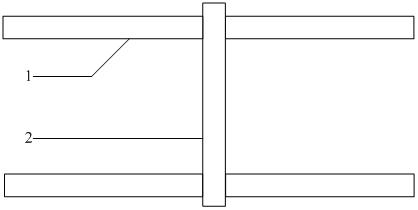

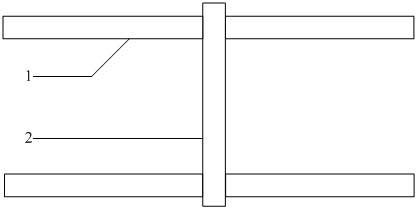

[0021] A welding workpiece, including: box plate 1, vertical rib partition 2; box plate 1 is an aluminum alloy thin plate, which is reinforced by a pressed square socket, and has an external dimension of 380mm×3000mm×2mm; the external dimension of the vertical rib partition 2 is 3000mm × 404mm × 1mm; the upper and lower ends of the vertical rib partition 2 are embedded in the box plate and protrude, and the protruding amount is 2mm.

[0022] The second step is to prepare the welding process equipment

[0023] Prepare the welding process equipment. The welding process equipment is an ordinary mechanical structure, and it is enough to ensure that the force on the joint area to be welded is uniform. Reliable positioning of the welding workpiece, preparation of retractable inner support and outer pressing mechanism, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com