Method for controlling deformation generated when connection pipe is welded to large-diameter thin-wall barrel

A thin-walled cylinder, welding deformation technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Small welding deformation, the effect of solving the collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A connecting pipe with a diameter of 1000mm is to be welded on a pre-rectification column, the material of the cylinder is Q345R, the diameter is φ3000mm, and the wall thickness is 14mm.

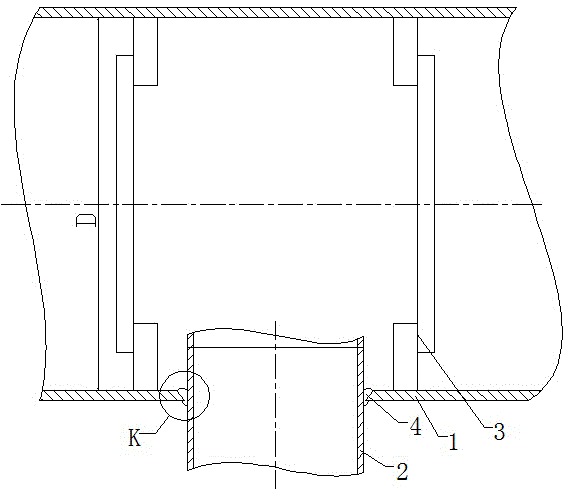

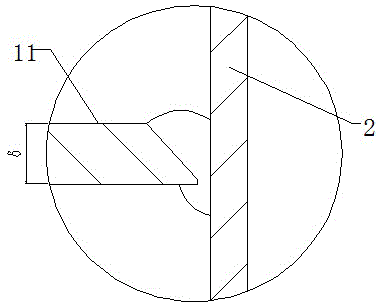

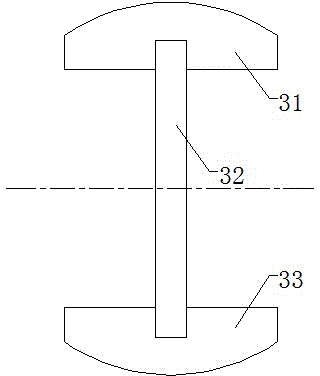

[0027] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the connecting groove 2 is opened on the cylinder body 1, the connecting groove 4 adopts the inner groove, and the internal support 3 is added inside the cylinder body 1, and the form of the internal support 3 is as follows image 3 , Figure 4 As shown, an inner support 3 is installed on the cylinder body 1 on both sides of the connecting pipe 2. After the connecting pipe 2 is adjusted in place, it is connected with the cylinder body 1 by spot welding, and then the connecting pipe 2 is turned to the bottom of the cylinder body 1.

[0028] like Figure 5 As shown, the entire circular weld 5 is divided into eight arc-shaped segmented welds, namely A1 segment, A2 segment...A8 segment, and each segmente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com