Preparation method for lithium sulfide self-supporting carbon sphere/carbon nanofiber composite material, and lithium-sulfur battery

A technology of carbon nanofibers and composite materials, applied in the direction of lithium batteries, battery electrodes, nanotechnology, etc., can solve the problems of reducing battery electrochemical performance, battery cycle capacity attenuation, active material loss, etc., to achieve the suppression of shuttle effect and adaptability Good, improved content and loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

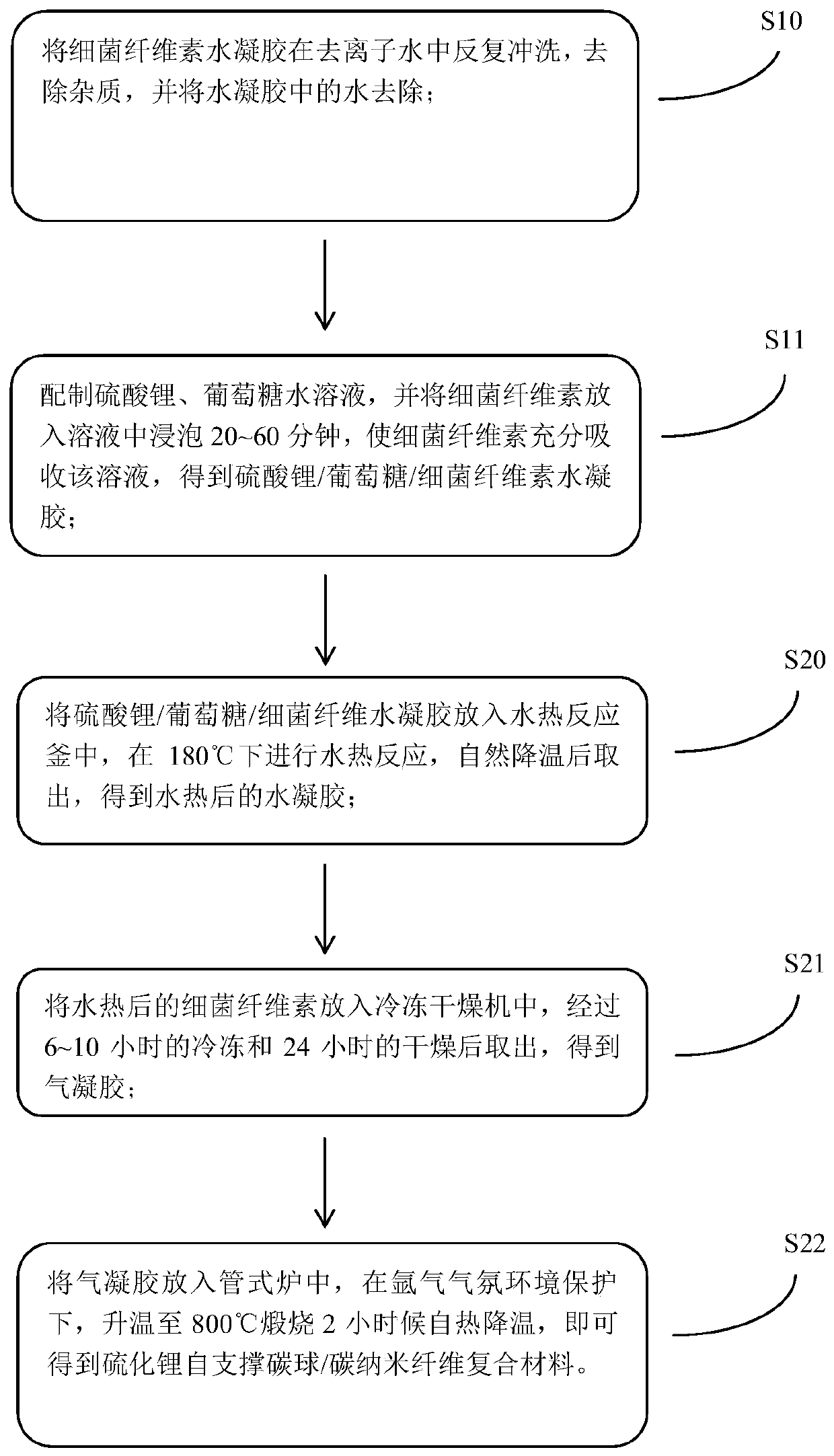

[0032] see figure 1 , the present invention proposes a method of utilizing bacterial cellulose hydrogel to prepare a lithium-sulfur battery positive electrode material of lithium sulfide self-supporting carbon sphere / carbon nanofiber composite material, comprising the following steps:

[0033] Step S1, preparing lithium sulfate / glucose / bacterial cellulose hydrogel composite material;

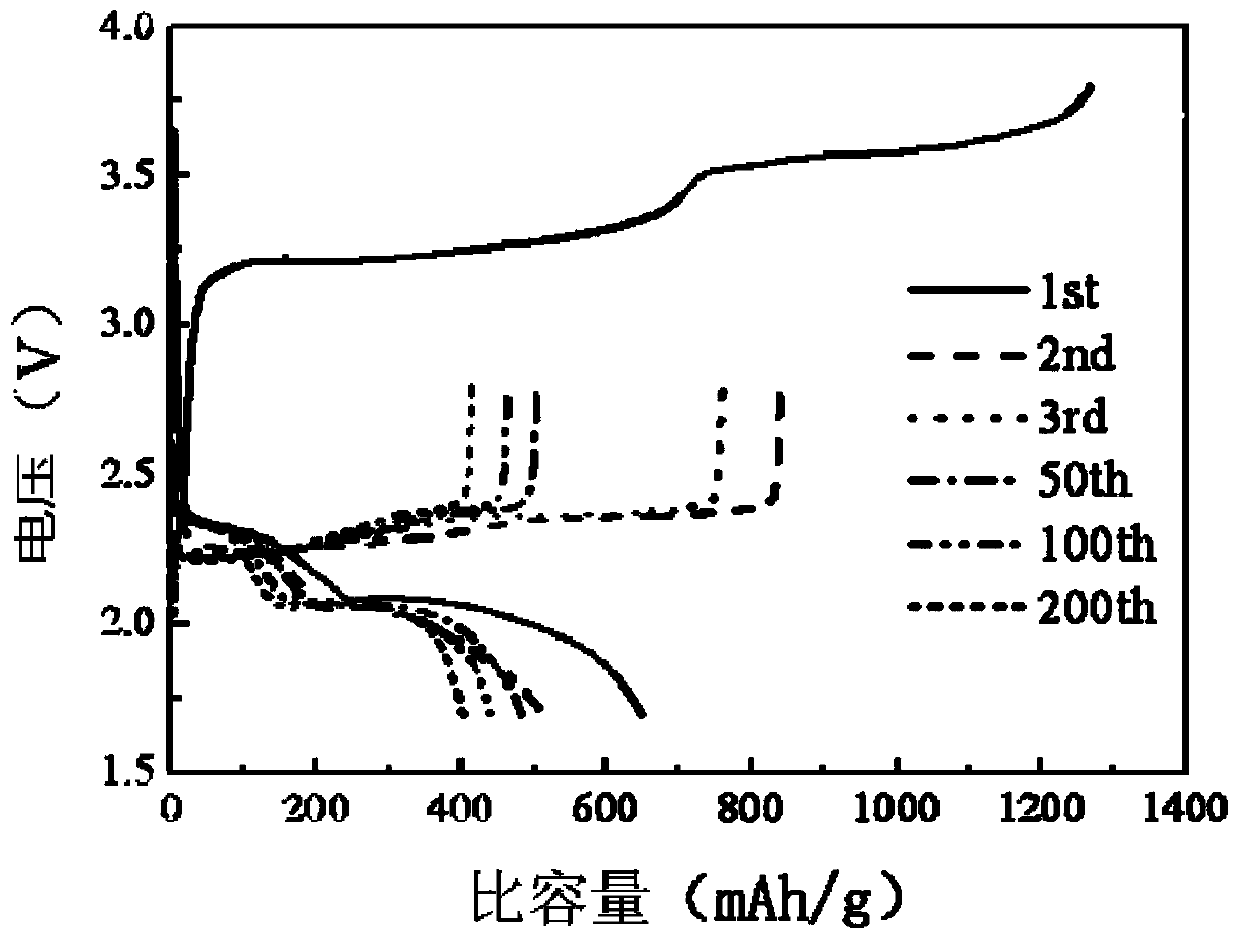

[0034] Step S2, converting the glucose in the lithium sulfate / glucose / bacterial cellulose hydrogel composite material into carbon spheres, so that the lithium sulfate is better covered by the carbon material, slowing down the diffusion of lithium polysulfide, and the bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com