Tubal curtain advanced support constructing method for deep mine roadway of coal mine passing through fault fracture zone

A technology for deep tunnels and construction methods, applied in tunnels, shaft equipment, shaft linings, etc., can solve the problems of delayed production, large deformation and instability due to extrusion, large-scale collapse, etc., achieving obvious effects, small impact on production progress, Simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described now in conjunction with accompanying drawing:

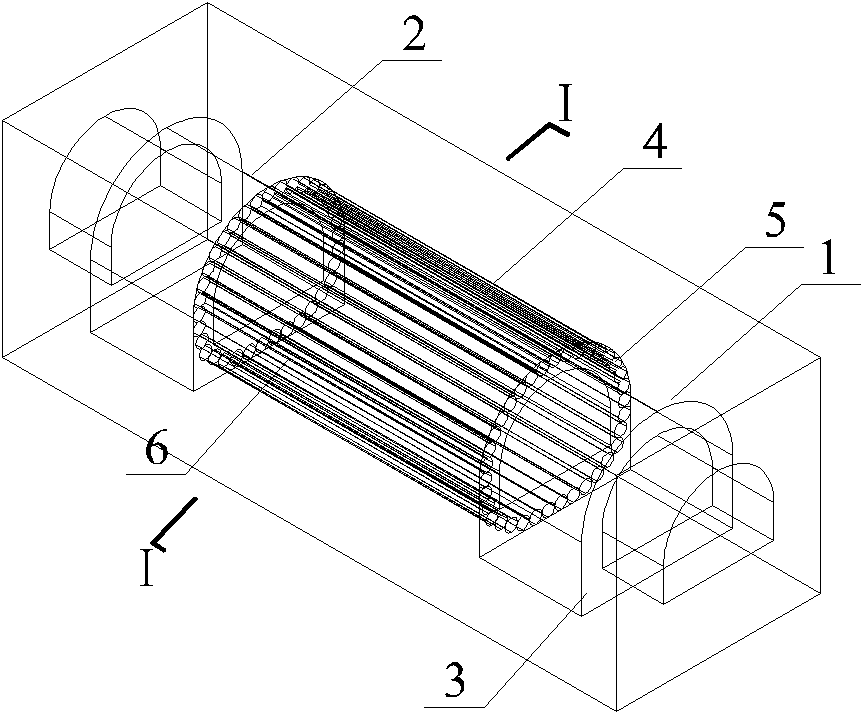

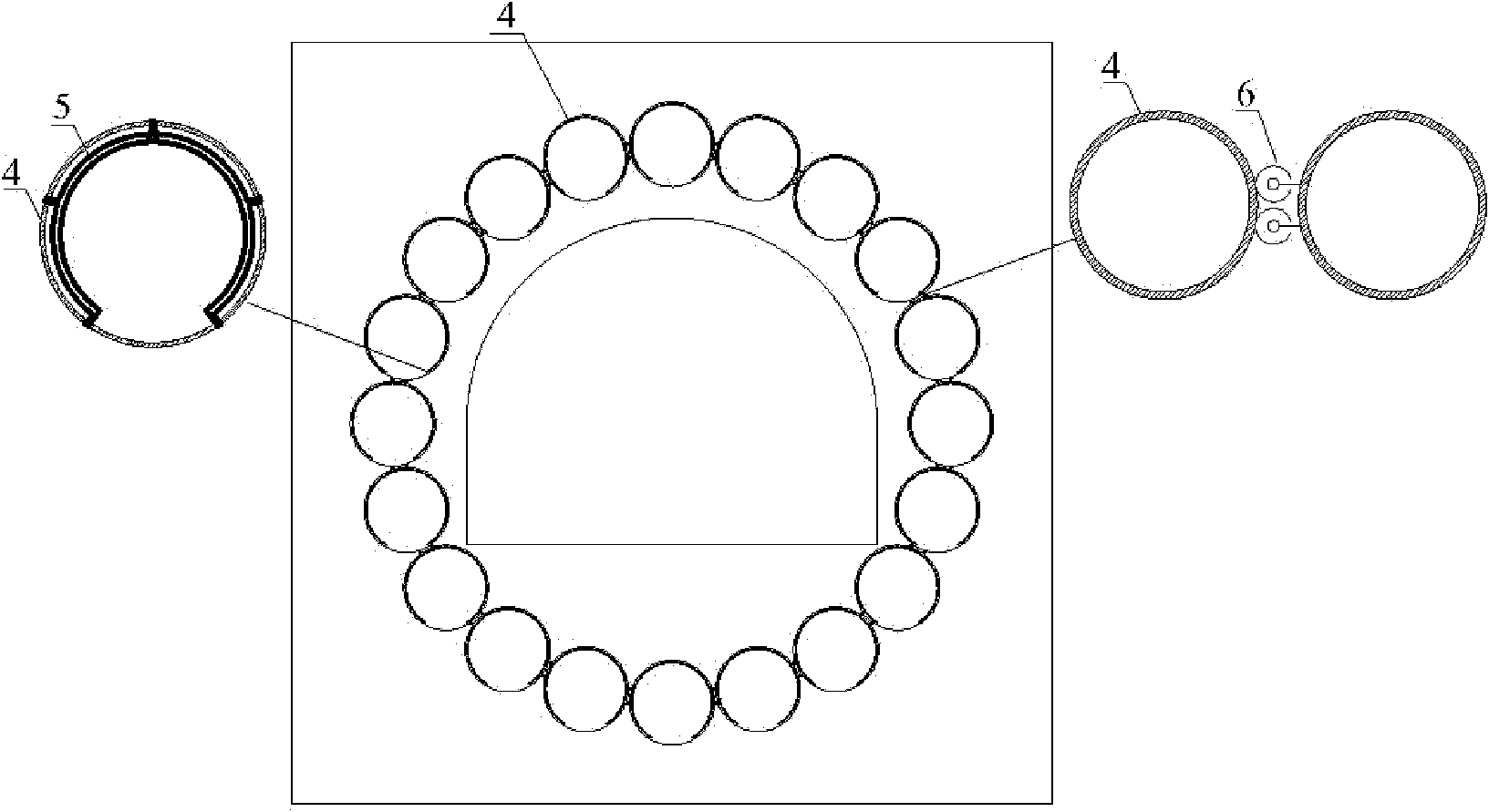

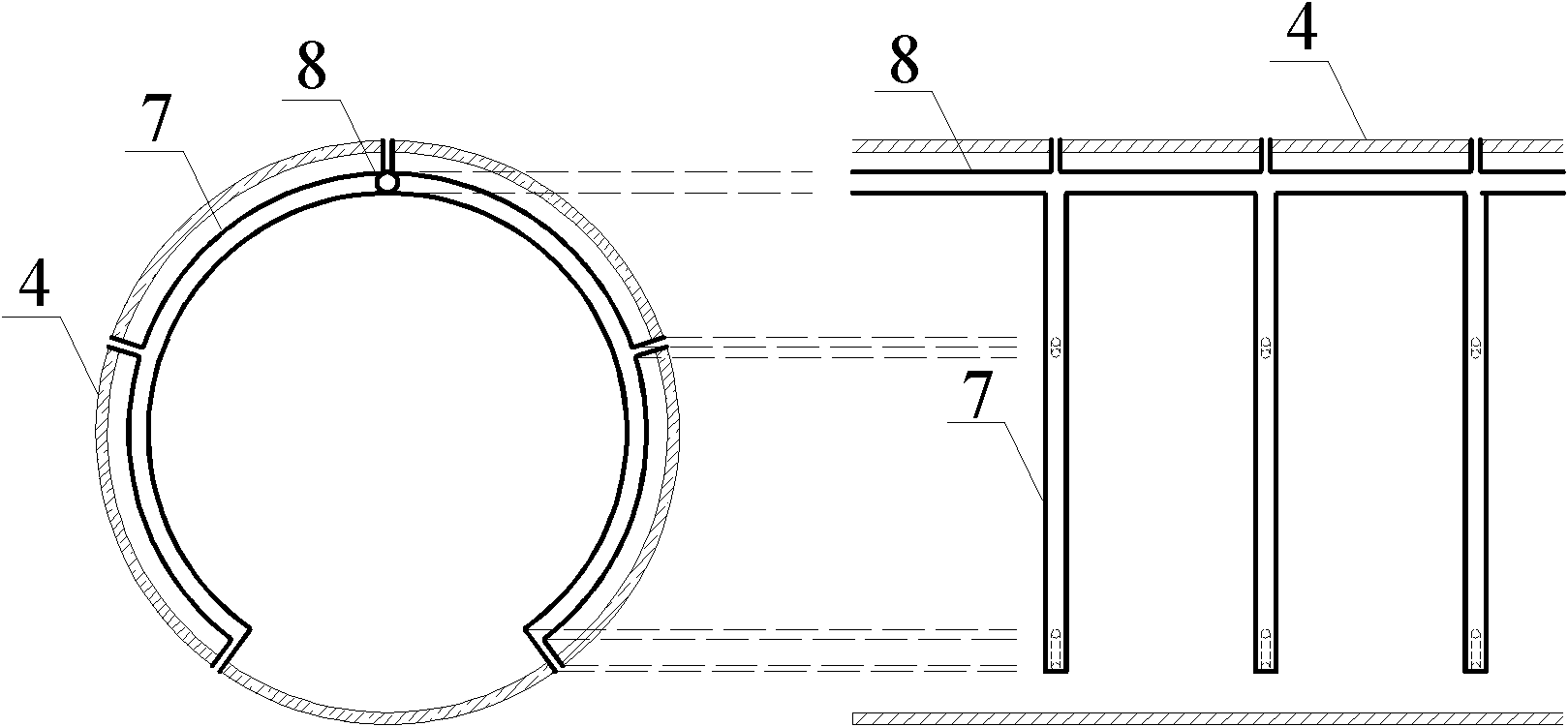

[0027] according to figure 1 , figure 2 , image 3 and Figure 4 It can be seen that the construction method for the pipe curtain advance support of a coal mine deep shaft roadway crossing the fault fracture zone provided by the present invention includes a starting working room 1 and a receiving working room 2, and a pipe curtain closed structure formed by connecting steel pipes 4 through locks 6. In addition, This construction method also includes: the counter force working surface 3 of the pipe jacking machine that provides counter force for the jacking process of the pipe jacking machine, the preset annular grouting system 5 in the steel pipe 4, and the connecting ring for connecting the axial steel pipe 4 9. Its specific implementation steps are:

[0028] A. Build the originating studio 1 and the receiving studio 2 at both ends of the fault fracture zone. The cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com