Molding process for plastic red wine goblet

A molding process and technology for red wine glasses, applied in the field of plastic manufacturing, can solve the problems of high manufacturing cost, many defective products, complicated processes, etc., and achieve the effects of good consistency, consistent molding effect, and neat and smooth cup mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] A molding process for plastic wine glasses, including five processes:

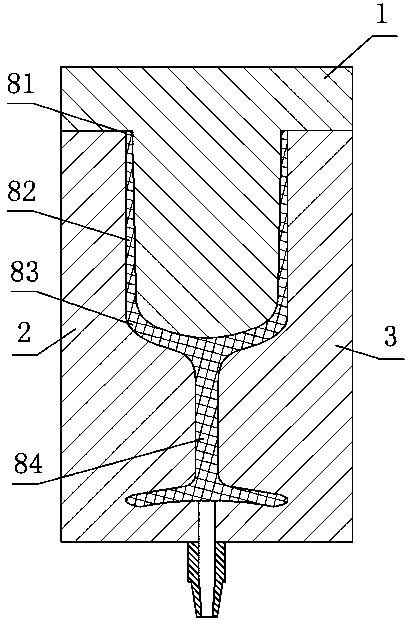

[0021] a. Injection molding: the primary product is obtained by demolding, the cup body is wide at the top and narrow at the bottom or straight, and the bottom is curved to close the bottom;

[0022] b. Mold clamping: transfer the primary product to the blow mold;

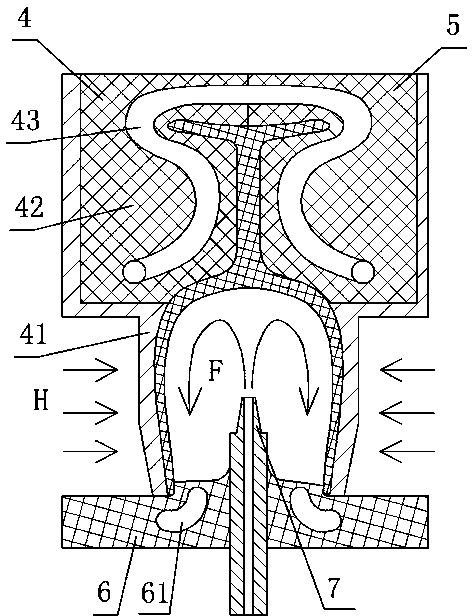

[0023] c. Heating: Put the mold with the primary product into the oven for heating, and the softening time is 30-40 seconds;

[0024] d: Blow molding: Blow for 8~12 seconds after closing the mold, and keep the air pressure at 25~28MPa;

[0025] e: demoulding, polishing treatment.

[0026] In this process, in the process of mold clamping, heating and blow molding, the plastic wine glass is in an upside-down state, with the mouth of the cup facing down and the tall part facing up; high-pressure air blows upward from the nozzle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com