MMW SMMW silicon-based on-chip end-on-fire antenna

A submillimeter-wave, end-fired antenna technology, applied in the direction of antenna, antenna support/mounting device, antenna grounding switch structure connection, etc., can solve the problems of low gain, reduced radiation efficiency, low resistivity, etc., and achieve simple structure, High efficiency, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

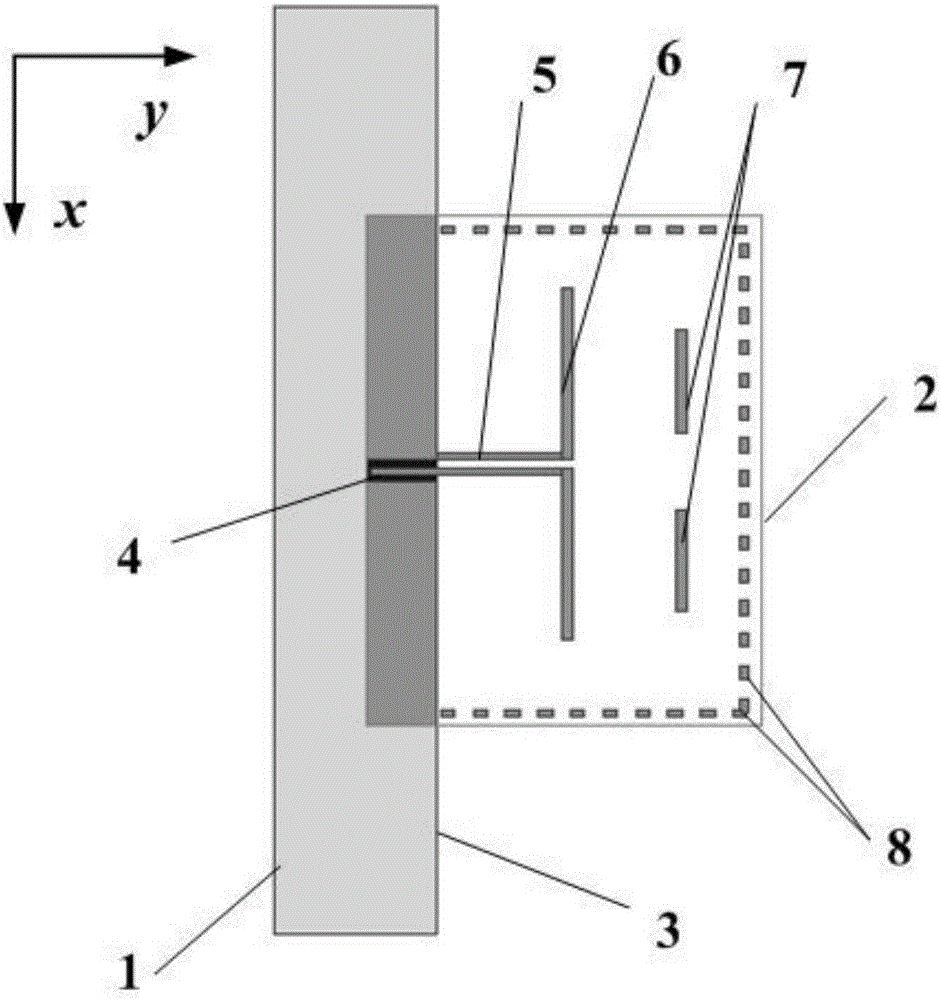

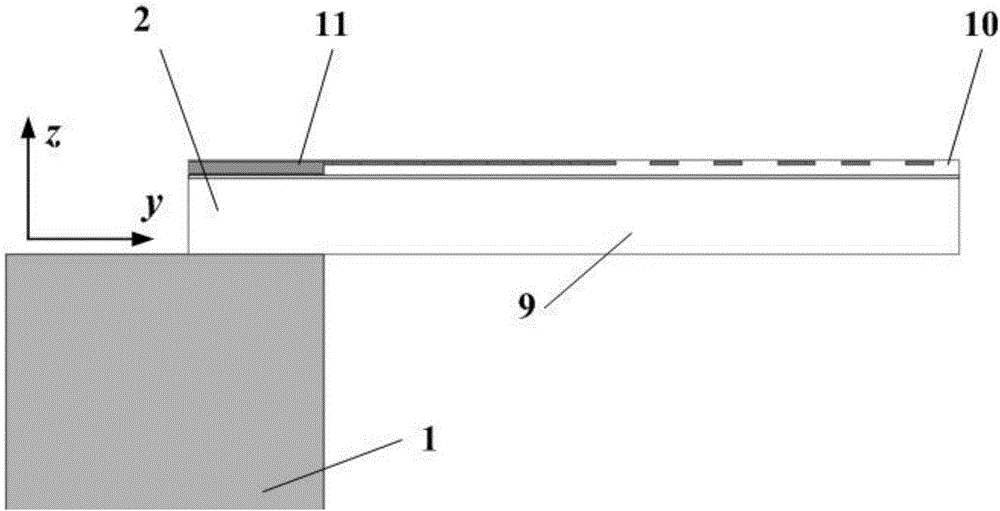

[0027] Such as Figure 1~4 As shown, a millimeter-wave and sub-millimeter-wave silicon substrate-mounted end-fire antenna includes a metal support platform 1, and an on-chip antenna 2 arranged on one side of the metal support platform; the on-chip antenna includes a silicon substrate 9, set SiO on the upper surface of silicon substrate 2 layer 10, and is arranged on the upper surface of the silicon substrate and is located in the SiO 2 The metal wiring layer 11 on one side of the layer; the metal wiring layer is located on the side of the on-chip antenna close to the metal support platform; the metal wiring layer is provided with a CPW feed port 4; the SiO 2 The layer is provided with a parallel double wire 5 connected to the CPW feed port, and is provided with a Yagi antenna active vibrator 6 connected with the parallel double wire; the side of the metal support table close to the on-chip antenna is provided with a reflective surface 3 , the reflector is combined with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com