Wear-free laminated spiral solid-liquid separator

A solid-liquid separator, spiral technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., to solve the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

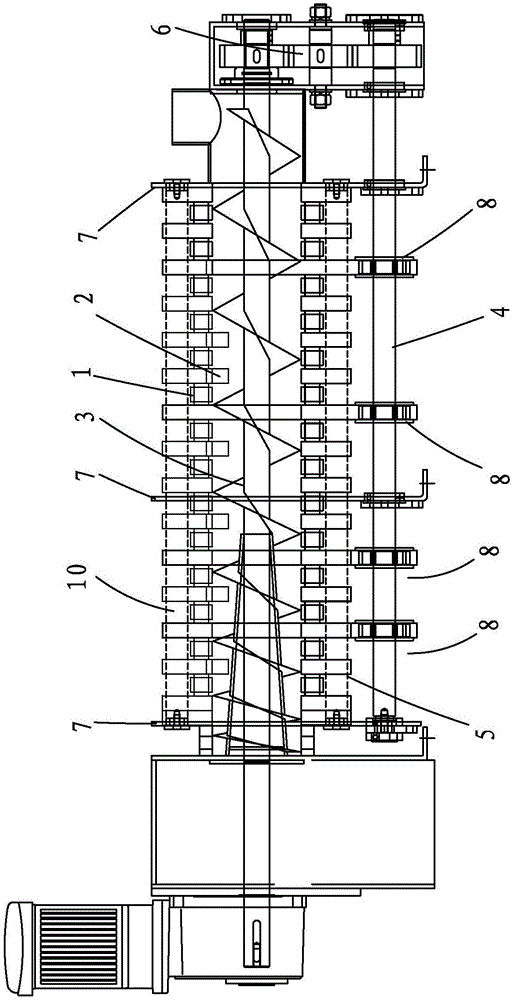

[0036] Such as figure 1 As shown, a wear-free laminated spiral solid-liquid separator includes a fixed ring 1, a movable ring 2, and a screw shaft 3, and the screw shaft 3 is radially provided with staggered fixed rings 1 and movable rings 2;

[0037] It also includes a main driving rod 4 and a secondary driving rod 5;

[0038] The screw shaft 3 is connected to the main drive rod 4 through a transmission mechanism 6, and the transmission mechanism 6 can be a gear transmission, a sprocket transmission, or a belt transmission;

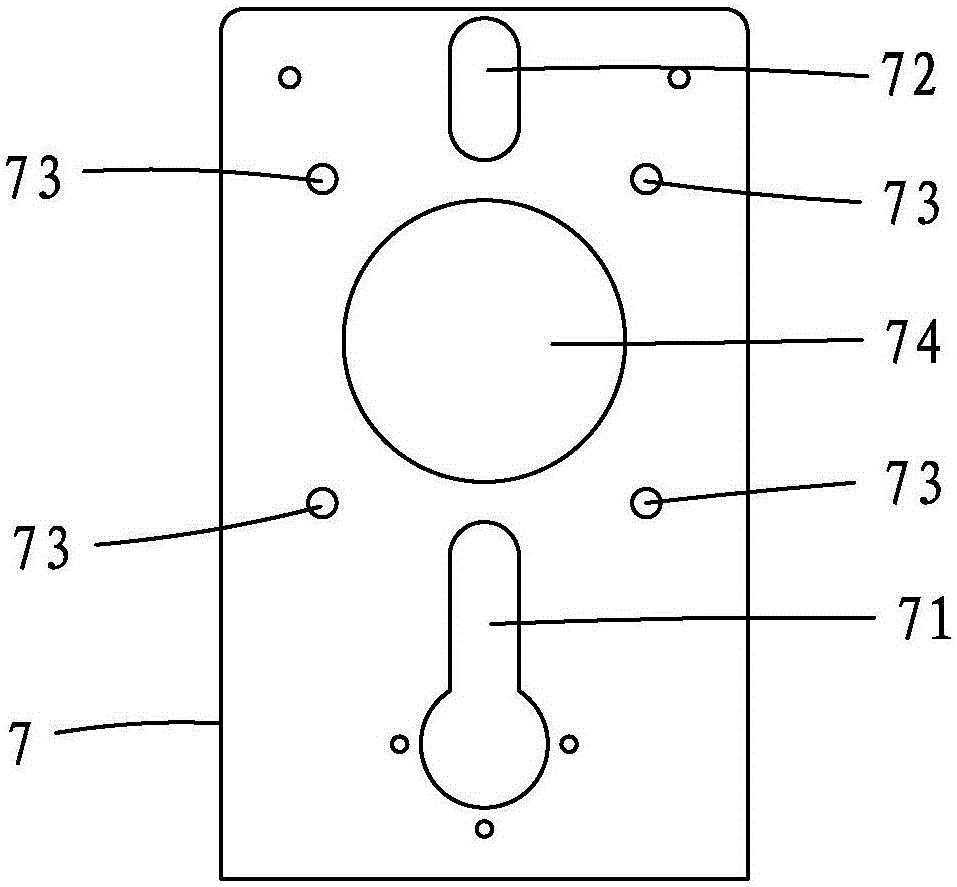

[0039] The main driving rod 4 is supported by three support plates 7, and four eccentric bearings 8 are arranged at intervals on the main driving rod 4;

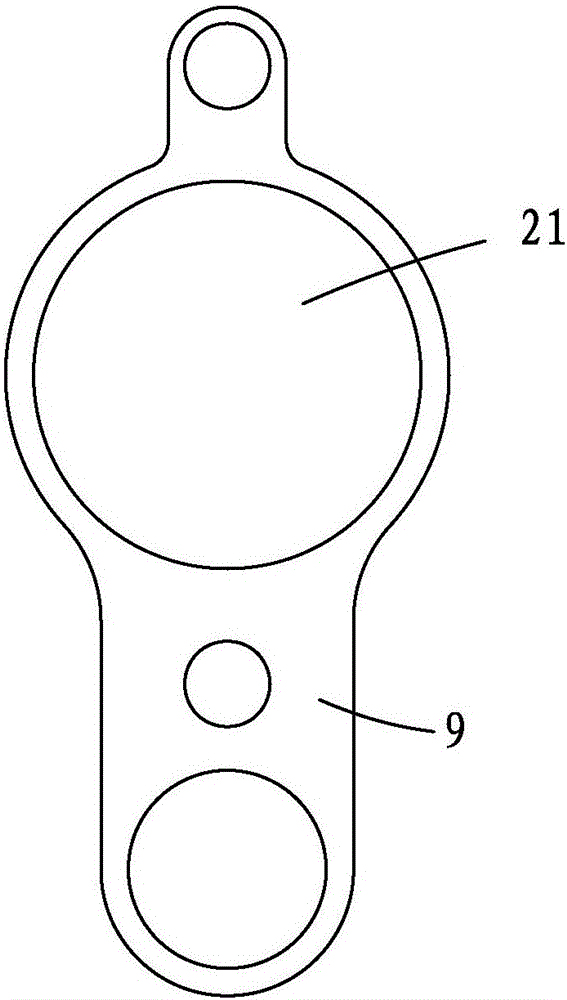

[0040] Each eccentric bearing 8 is respectively connected to the auxiliary driving rod 5 through a driving piece 9, and the auxiliary driving rod 5 is sheathed on one end of the movable ring 2 to connect all the movable rings 2 as a whole. And the drive piece 9 is integrated with the movable ring 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com