Ultrasonic suspension conveying device

A transmission device, ultrasonic technology, used in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of pollution, mechanical damage particles of transmission objects, etc., to achieve wide application prospects, high energy utilization and electromechanical conversion efficiency, Resolve the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

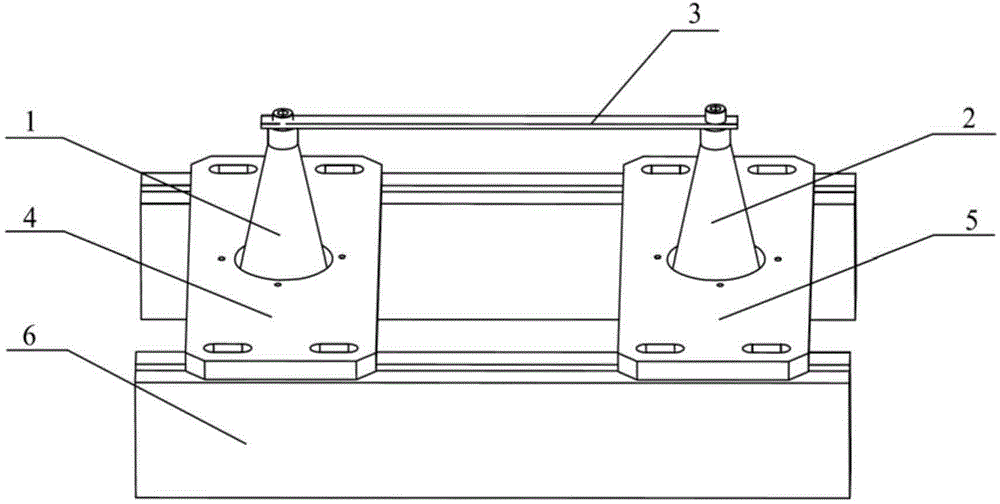

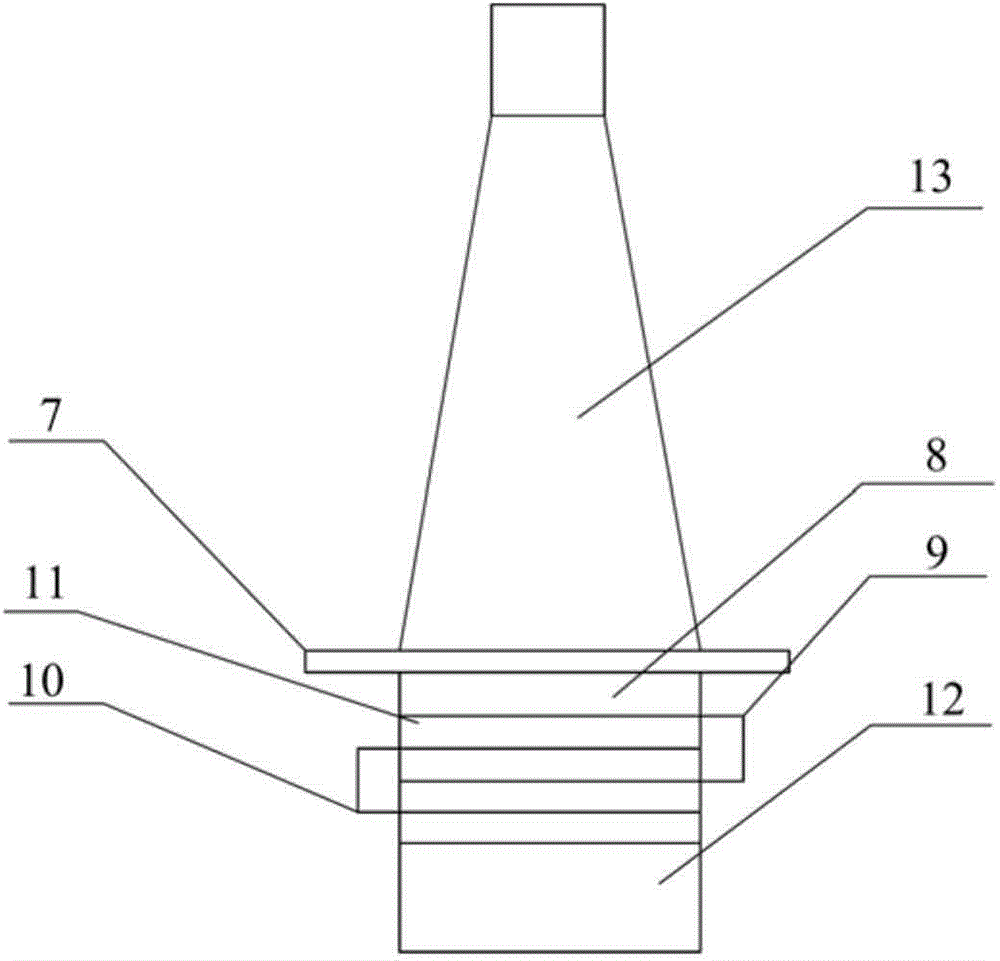

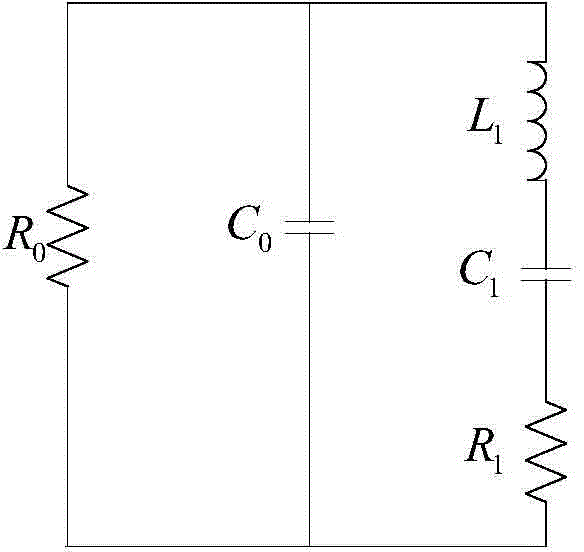

[0041] The ultrasonic levitation transmission device proposed by the present invention connects two prestressed stacked ultrasonic transducers by a transmission track. By applying a simple harmonic voltage to the electrodes of a stacked ultrasonic transducer, the inverse piezoelectric effect of the piezoelectric material is used to generate mechanical vibration, and the energy gathering effect of the horn is used to gather energy, and the vibration energy passes through the horn and the transmission track. The connection part makes the transmission track produce the same simple harmonic vibration, and the vibration of the transmission track makes the interaction between the transmission track and the squeezed air film generate an upward suspension force, so that the object to be transported is suspended; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com