Heat conduction material co-extruded with optical diffusion material, and preparation method thereof

A heat-conducting material and co-extrusion technology, which is applied in the field of polycarbonate resin composite materials, can solve the problems of insufficient strength and deformation of all-plastic LED fluorescent tubes, and achieve the effects of light weight, pollution reduction and deformation resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

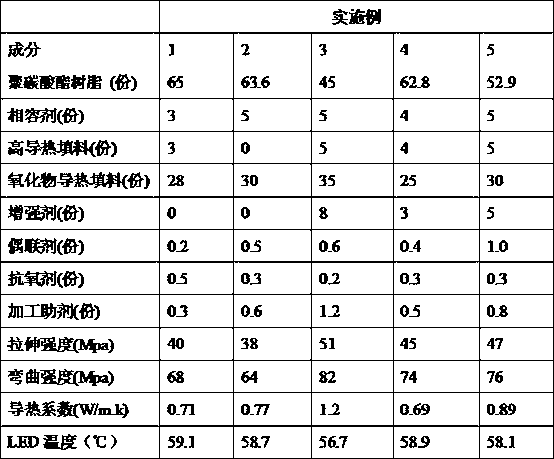

Embodiment 1

[0025] In terms of parts by mass, 3 parts of aluminum nitride and 28 parts of aluminum oxide are first treated with 0.2 parts of silane coupling agent, and then the treated thermal conductive filler and 65 parts of PC, 3 parts of methyl methacrylate-butane Acrylic-styrene copolymer, 0.5 part of antioxidant 1076 and 0.3 part of pentaerythritol stearate are mixed homogeneously in high-speed mixer, join the feeding hopper of twin-screw extruder, through melt extruding, granulate, at 250 ℃ or so extrusion granulation and injection molding into samples.

Embodiment 2

[0027] In terms of parts by mass, 30 parts of magnesium oxide are first treated with 0.5 parts of silane coupling agent, and then the treated thermally conductive filler and 63.6 parts of PC, 5 parts of methyl methacrylate-butadiene-styrene copolymer , 0.3 parts of antioxidant 1076 and 0.6 parts of pentaerythritol stearate are mixed evenly in a high-speed mixer, added to the hopper of a twin-screw extruder, melted and extruded, granulated, and extruded at about 250 ° C for granulation And injection molded into samples.

Embodiment 3

[0029] In terms of parts by mass, 5 parts of boron nitride and 35 parts of aluminum oxide are first treated with 0.6 parts of titanate coupling agent, and then the treated thermal conductive filler and 45 parts of PC, 5 parts of styrene-maleic anhydride Copolymer, 8 parts of tetraacicular zinc oxide whiskers, 0.2 parts of antioxidant 168 and 1.2 parts of silicone lubricating and dispersing agent were mixed uniformly in a high-speed mixer, added to the hopper of a twin-screw extruder, and melted and extruded , pelletized, extruded pelletized at around 250°C and injection molded into samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com