Method for processing split thin-walled parts

A technology of thin-walled parts and a processing method, which is applied in the processing field of split thin-walled parts, can solve problems such as deformation of open thin-walled parts, and achieve the effect of solving the deformation problem and improving the level of manufacturing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

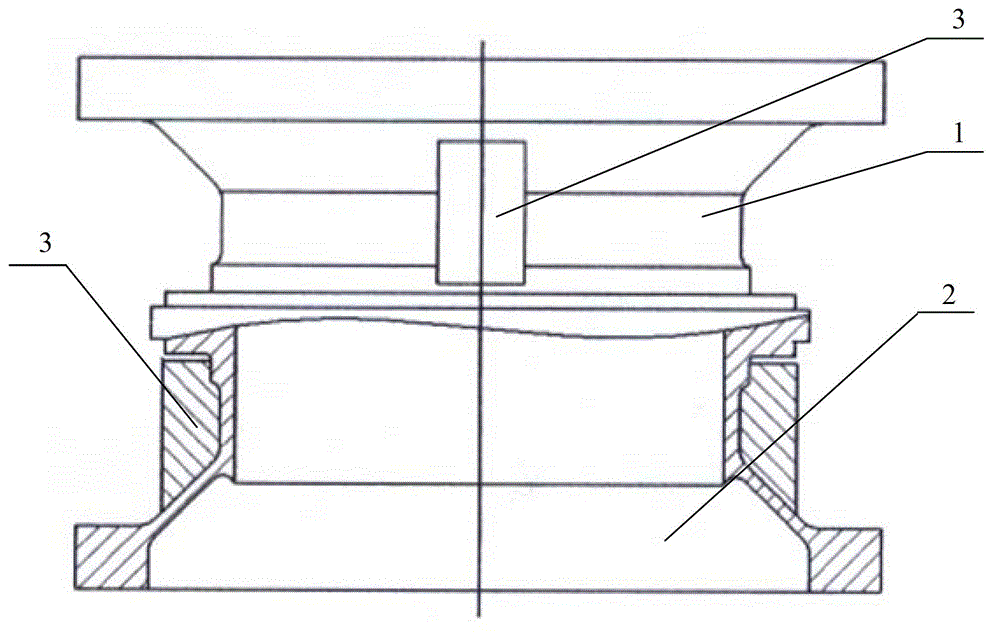

[0043] Finished parts after processing: The parts are split-type thin-walled ring parts, which are composed of upper half rings, lower half rings, longitudinal mounting edges and bolts. The materials of the upper and lower half rings are superalloys. The main dimensions and technical conditions are: the maximum diameter of the part is Ф380mm, the height is 56.5mm, and the inner circle size is Ф279 +0.09 mm, the wall thickness is 2±0.12mm, the outer circle is not allowed to be processed after welding the two half-rings and the longitudinal mounting edge, and the jump between the inner circle and the reference is required to be 0.03mm, and the two half-rings are assembled by bolts.

[0044] Processing method of the present invention specifically comprises the steps:

[0045] Step 1: blank selection,

[0046] The blank adopts ring forging, and one blank is selected to process two parts;

[0047] Step 2: Before welding the ring forging, the two parts are roughly processed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com