Ladder waveform steel plate and steel truss combined assembled envelop enclosure structure and construction method thereof

A corrugated steel plate and enclosure structure technology, which is used in foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of low rigidity of foundation pit enclosure structure, large impact on surrounding environment, and inability to be used repeatedly, and achieves high construction efficiency. , Reducing the influence of deformation, the effect of good soil and water retaining functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

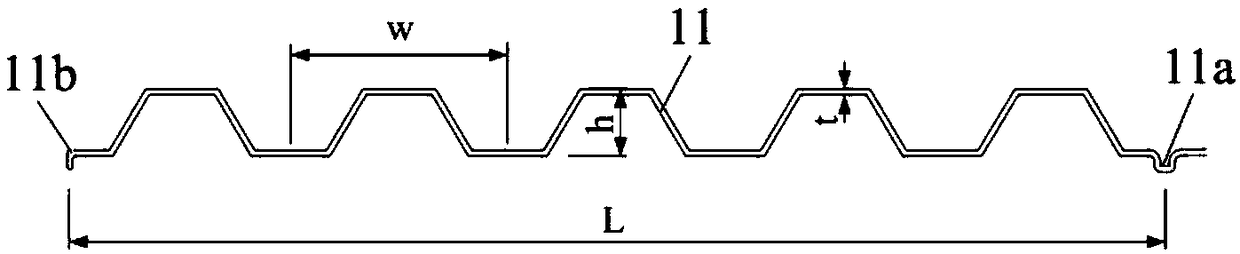

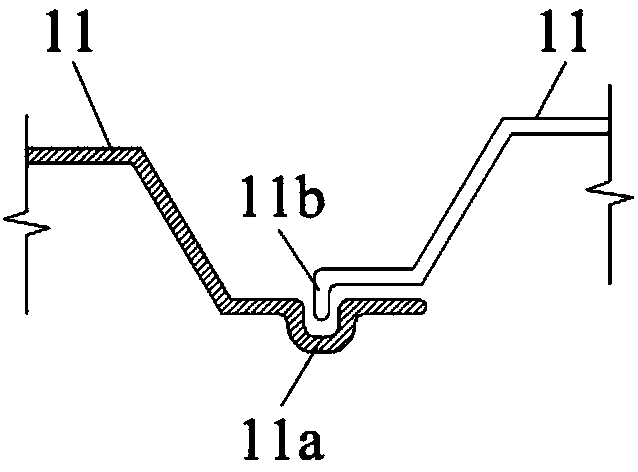

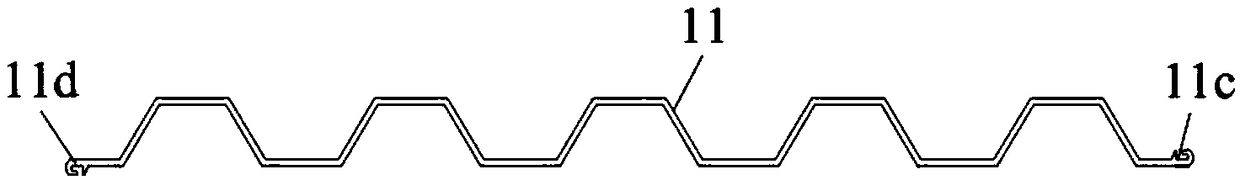

[0061] Example 1: Combining Figure 1-6 and Figure 11 , Figure 12 Illustrate the assembled enclosure structure 10 of the combination of ladder corrugated steel plate and steel truss of the present invention, it is formed by continuous splicing of a plurality of enclosure structure units, as Figure 5 with Image 6 As shown, each enclosure structure unit includes two ladder corrugated steel plates 11 parallel to each other, and the two ladder corrugated steel plates 11 are respectively arranged on the pit facing surface E and the soil facing surface F of the foundation pit 1, and are connected to the two ladder corrugated steel plates Between 11 and a plurality of steel trusses 15 arranged along its height direction, the height direction of the ladder corrugated steel plate 11 is the depth direction of the foundation pit 1; A plurality of connecting rods 12 of the ladder corrugated steel plate 11 and the steel truss 15, the enclosure structure unit here refers to a section...

Embodiment 2

[0082] Embodiment two: combine Figure 1-6 and Figure 11 , Figure 12 Illustrate the construction method of the prefabricated enclosure structure of the combination of ladder corrugated steel plate and steel truss in the first embodiment of the present invention, the specific steps are as follows:

[0083] S1: Determine the appropriate enclosure structure unit model according to the design requirements, and prefabricate and process multiple enclosure structure units. Each enclosure structure unit is composed of two ladder corrugated steel plates 11, connected between the two ladder corrugated steel plates 11 and along the A plurality of steel trusses 15 arranged in the height direction, and a plurality of connecting rods 12 connected between the ladder corrugated steel plates 11 and the steel trusses 15 are fixedly connected as a whole, and the gap between the ladder corrugated steel plates 11, the steel trusses 15 and the connecting rods 12 The nodes are connected by facto...

Embodiment 3

[0091] Embodiment three: different from embodiment one, as Figure 7 to Figure 12 As shown, the enclosure structure unit includes: a trapezoidal corrugated steel plate composite member fixedly connected with connecting rods and connectors, and a steel truss composed of chords and web members. The connectors 17 have a flat C-shaped or Ω-shaped cross-section, and multiple The connecting piece 17 is set through the height direction of the ladder corrugated steel plate 11 and is fixedly connected with the connecting rod 12 and the ladder corrugated steel plate 11 to form a composite member of the ladder corrugated steel plate. A plurality of steel trusses 15 are detachably connected to the two oppositely arranged connectors In 17, the ladder corrugated steel plate composite members and steel trusses 15 can be prefabricated separately in the factory, and then transported to the construction site to adopt the prefabricated construction of "component inserting and driving", and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com